2025 Market Insights: How to Choose the Best CNC Vertical Machining Center for Your Business

In the rapidly evolving landscape of manufacturing, the choice of a CNC vertical machining center (VMC) has become pivotal for businesses aiming to enhance productivity and maintain competitiveness. According to a recent market report by Grand View Research, the global CNC machining market is expected to reach $100.9 billion by 2025, reflecting a growing demand for precision and efficiency across various sectors. One of the critical factors influencing the selection of a VMC is the after-sales service advantages and repair costs, which can significantly impact long-term operational efficiency.

As manufacturers increasingly seek advanced features and digital capabilities, understanding how to navigate these elements is essential. This blog will provide valuable insights and tips on choosing the best CNC vertical machining center that aligns with your business needs, ensuring you make an informed investment that drives success in the coming years.

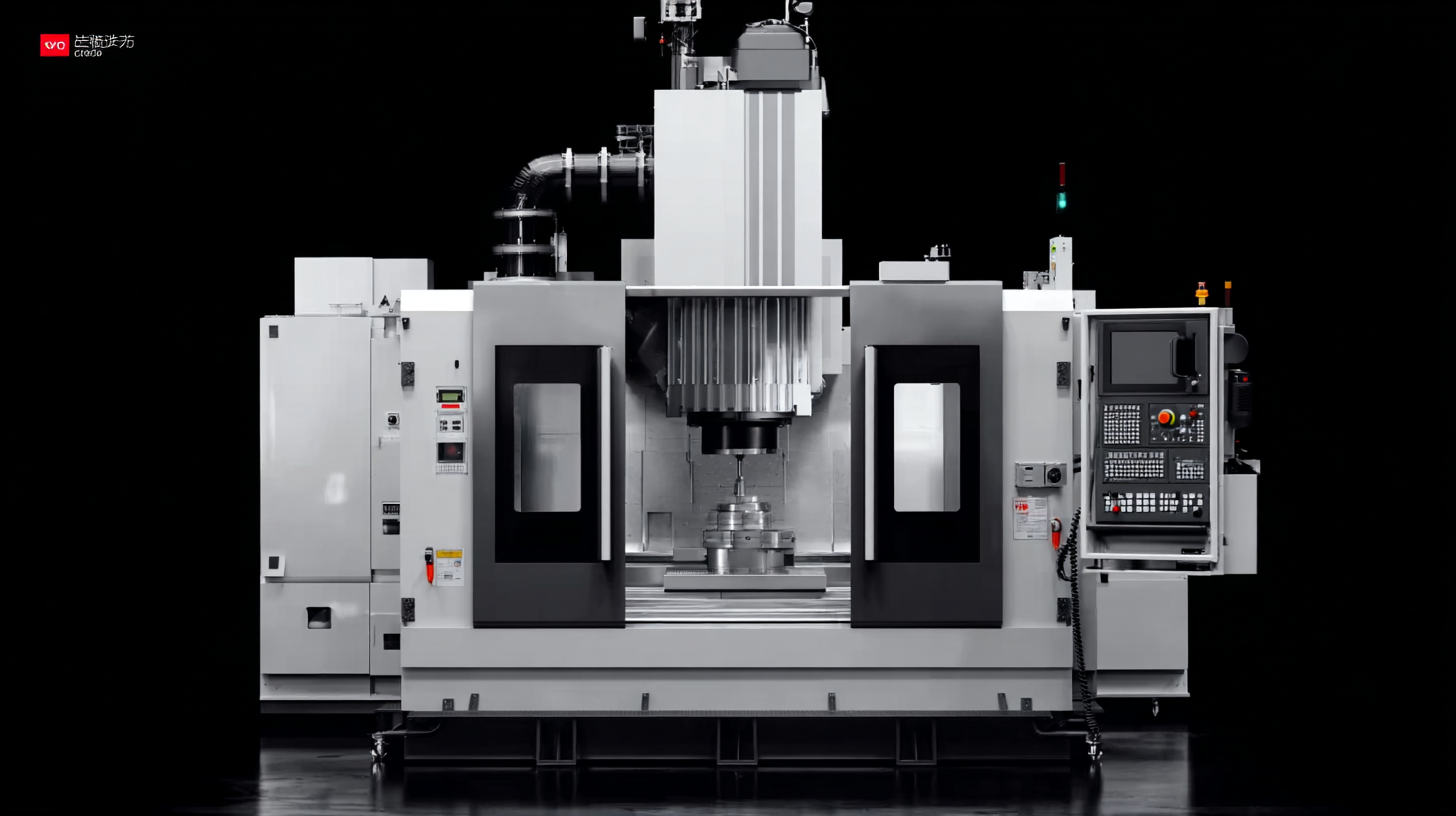

Understanding the Types of CNC Vertical Machining Centers Available in 2025

In 2025, choosing the right CNC vertical machining center (VMC) for your business is crucial for enhancing productivity and staying competitive in the market. The landscape of CNC vertical machining centers has evolved significantly, offering a diverse range of options tailored to meet various manufacturing needs. The main types of VMCs include standard vertical machining centers, high-speed VMCs, and multi-axis VMCs, each designed for specific applications such as precision tooling, complex geometries, or high-volume production.

As the CNC machining sector is projected to grow substantially, expected to reach $195.59 billion by 2032, understanding these different types of VMCs becomes essential. Standard vertical machining centers are versatile and can handle a variety of tasks, while high-speed VMCs are optimized for faster feed rates and cutting, making them ideal for intricate designs. Multi-tasking VMCs, on the other hand, combine the functions of milling and turning, providing greater flexibility. With advancements in technology and an expanding market, selecting the right VMC will not only streamline operations but also enhance overall efficiency and capability in meeting client demands.

Key Factors to Consider When Selecting a CNC Vertical Machining Center for Your Business

When selecting a CNC vertical machining center for your business, understanding key factors is crucial to ensure optimal performance and alignment with your operational goals. The market for CNC machining centers has seen significant growth, projected to reach a value of approximately $291.7 billion by 2032, with a compound annual growth rate of 4.9% during the forecast period. This growth indicates not only increasing demand but also advancements in technology that can impact your purchasing decisions.

Tips: First, consider the machine's precision and reliability. Look for features such as robust construction, quality components, and advanced control systems that enhance accuracy. Additionally, assess the machining center's flexibility to handle various materials and part sizes. This adaptability can be vital as your business evolves.

Another vital aspect is the availability of support and service. A reputable manufacturer should provide comprehensive after-sales support, including maintenance and troubleshooting. This ensures that your machining center operates smoothly, minimizing downtime and associated costs. Finally, evaluate the machine's compatibility with your existing setups and workflow processes to ensure seamless integration into your operations.

2025 Market Insights: CNC Vertical Machining Center Features Comparison

This chart illustrates the key features to consider when selecting a CNC Vertical Machining Center for your business in 2025. Each feature is rated on a scale from 1 to 10, providing insights into their relative importance and effectiveness in manufacturing operations.

Evaluating CNC Vertical Machining Center Features: What Matters Most in 2025

When evaluating CNC vertical machining centers for your business in 2025, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, the control system plays a crucial role. Look for machines equipped with advanced software that supports intuitive programming and real-time monitoring. This not only enhances precision but also streamlines the production process, allowing for quicker adjustments and less downtime.

Another essential consideration is the machine's rigidity and design. A robust construction minimizes vibrations during operation, which directly affects the quality of the machined parts. Moreover, an ergonomic design can significantly improve operator comfort and safety, which is particularly important for operations with high machine utilization. Finally, consider the flexibility of the CNC vertical machining center. Models that offer modular tooling systems or the capability to handle different materials are invaluable as they allow businesses to adapt to changing demands and optimize productivity across various projects.

Budgeting Strategies: Cost vs. Value of CNC Vertical Machining Centers for Your Operations

When investing in CNC vertical machining centers, it is crucial for businesses to strike a balance between cost and value. A recent industry report highlights that the average price of a decent CNC vertical machining center ranges from $50,000 to over $150,000, depending on the specifications and capabilities. However, purchasing decisions should not solely be based on upfront costs; understanding the long-term value these machines can provide is essential. Companies should consider factors such as precision, operational speed, and maintenance requirements, which can significantly impact overall productivity and profitability.

Moreover, as the manufacturing landscape becomes increasingly competitive, the emphasis on advanced technology has never been greater. For instance, investing in machines with a higher helix angle can improve cutting force efficiency and optimize chip formation, resulting in better machining outcomes. According to a comprehensive study, the right machining center can increase production efficiency by up to 30% and reduce operational costs over time. Therefore, businesses should employ strategic budgeting that not only accounts for initial purchase prices but also the ongoing costs and returns associated with enhanced machining capabilities. Choosing the right CNC vertical machining center is not just a financial decision; it is a strategic move that can profoundly influence a company’s operational success.

Moreover, as the manufacturing landscape becomes increasingly competitive, the emphasis on advanced technology has never been greater. For instance, investing in machines with a higher helix angle can improve cutting force efficiency and optimize chip formation, resulting in better machining outcomes. According to a comprehensive study, the right machining center can increase production efficiency by up to 30% and reduce operational costs over time. Therefore, businesses should employ strategic budgeting that not only accounts for initial purchase prices but also the ongoing costs and returns associated with enhanced machining capabilities. Choosing the right CNC vertical machining center is not just a financial decision; it is a strategic move that can profoundly influence a company’s operational success.

Future-Proofing Your Investment: Choosing CNC Vertical Machining Centers for Long-Term Success

When it comes to investing in a CNC vertical machining center, future-proofing your choice is essential for ensuring long-term success. Machining technology is evolving rapidly; therefore, selecting equipment that can adapt to changes in manufacturing processes and market demands is crucial. Consider factors such as compatibility with advanced software and the ability to integrate automation features. Investing in a machine with a robust architecture and a reputation for reliability will provide the flexibility needed to incorporate future enhancements without necessitating a complete overhaul of your operations.

Moreover, assess the manufacturer’s support and upgrade options. A strong warranty and responsive customer service can save significant downtime in the future. Additionally, factories that offer continuous training and education for operators will help you maximize the capabilities of the CNC vertical machining center over its lifespan. Choosing a model that accommodates a wide range of materials and tooling options will allow your business to pivot swiftly as trends and technologies progress, ensuring that your investment remains relevant in an ever-changing landscape.