Insights on Best CNC Lathe Parts in 2025 Industry Trends and Comprehensive Comparison Guide

As we look ahead to 2025, the CNC lathe parts industry is poised for significant transformation, driven by advancements in technology and shifting market demands. This blog aims to provide insights into the best CNC lathe parts available, highlighting their characteristics, applications, and benefits. Understanding the different types of CNC lathe parts—ranging from high-speed spindles to precision tool holders—will not only help manufacturers optimize their production processes but also enhance the quality of their final products. Additionally, we will explore the latest trends influencing these components, ensuring that readers are well-equipped to make informed decisions in an ever-evolving landscape. Whether you are a seasoned professional or new to the industry, this comprehensive comparison guide will serve as a valuable resource for navigating the intricate world of CNC lathe parts.

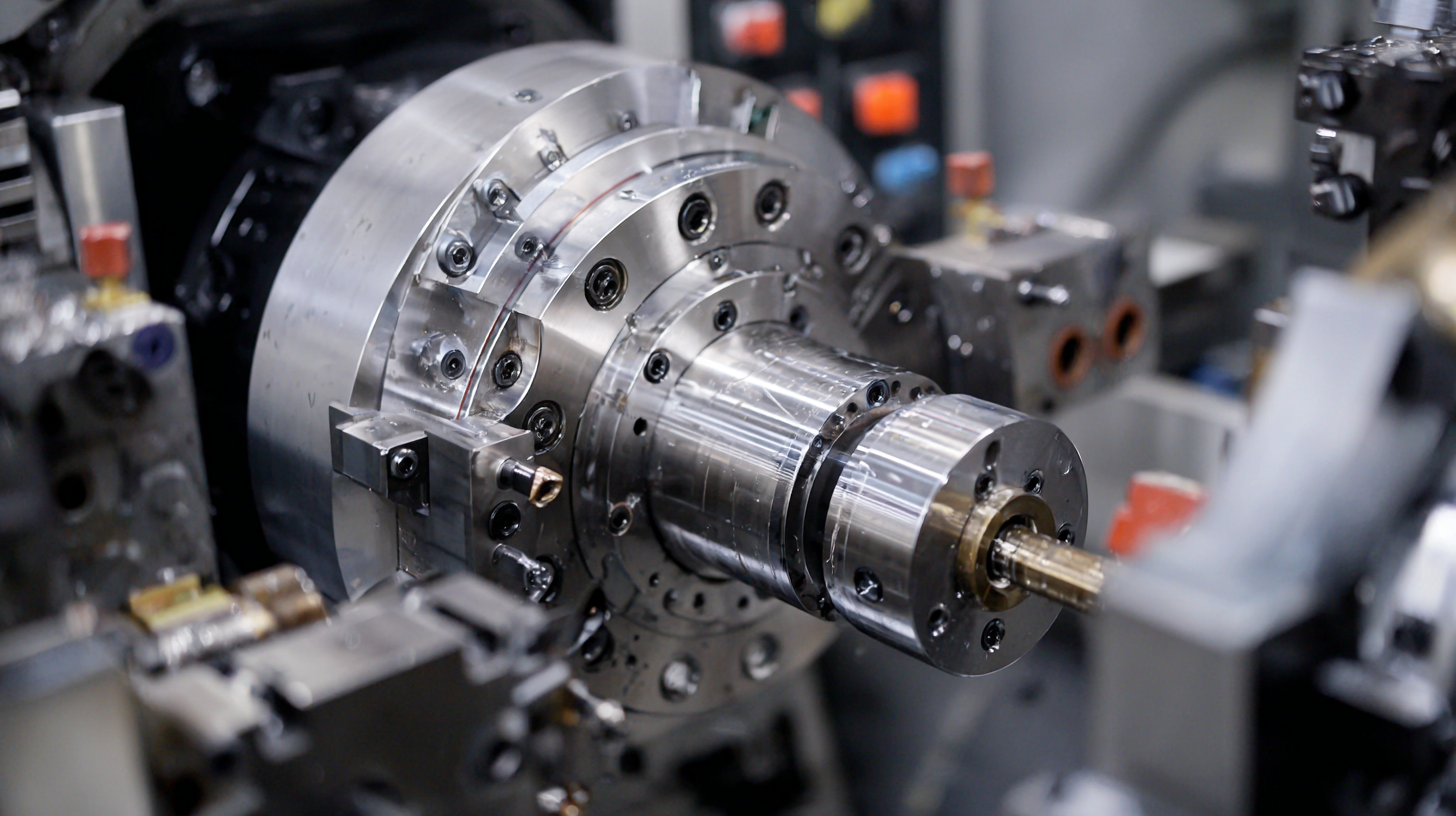

Best CNC Lathe Parts to Enhance Precision Manufacturing in 2025

In 2025, precision manufacturing will hinge significantly on the selection of CNC lathe parts that enhance efficiency and accuracy. The industry is witnessing an upward trend in the use of advanced tool holders, which are becoming essential for maximizing machining precision. These tool holders are designed to securely hold cutting tools, ensuring that operators achieve the highest quality finishes—an important requirement in sectors like aerospace and medical manufacturing.

Tip 1: When selecting CNC lathe parts, prioritize tool holders that offer superior grip and stability. This will not only improve precision but also extend the life of your tools and reduce downtime.

Moreover, recent advancements in shopfloor optical inspection technology are revolutionizing production processes. Implementing such inspection systems can drastically enhance production efficiency by enabling real-time quality control, thus minimizing errors and waste.

Tip 2: Invest in integrated inspection tools that can provide immediate feedback during the machining process. This will help in swiftly identifying and correcting any deviations, ensuring that your production stays on track.

As the CNC machine market continues to grow, staying updated with the latest trends and technologies will be crucial for manufacturers looking to enhance their capabilities and maintain a competitive edge.

Emerging CNC Lathe Technologies and Their Impact on Industry Productivity

In the rapidly evolving landscape of CNC lathe technology, 2025 is poised to witness significant advancements that will reshape industry productivity. Emerging technologies, such as artificial intelligence and machine learning, are being integrated into CNC lathes, allowing for real-time data analysis and adaptive machining processes. These innovations facilitate enhanced precision and reduced cycle times, enabling manufacturers to respond more quickly to market demands and increasing overall efficiency.

In the rapidly evolving landscape of CNC lathe technology, 2025 is poised to witness significant advancements that will reshape industry productivity. Emerging technologies, such as artificial intelligence and machine learning, are being integrated into CNC lathes, allowing for real-time data analysis and adaptive machining processes. These innovations facilitate enhanced precision and reduced cycle times, enabling manufacturers to respond more quickly to market demands and increasing overall efficiency.

Additionally, advancements in materials and tooling technology are set to revolutionize machining capabilities. The introduction of high-performance alloys and coatings can improve tool longevity and maximize productivity, reducing downtime for maintenance and tool changes. Moreover, automated features, such as predictive maintenance and remote monitoring, empower operators to ensure optimal machine performance, thus minimizing disruptions. As these technologies gain traction, businesses that invest in modern CNC lathe systems will benefit from higher output quality and improved operational agility in a competitive market.

Key Factors Driving CNC Lathe Parts Innovation in 2025 and Beyond

The CNC lathe parts market is poised for significant transformation as we move towards 2025. Key factors driving this innovation include advancements in automation technology, the rising demand for precision machining, and the integration of IoT in manufacturing processes. With the global CNC machine market projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, achieving a remarkable compound annual growth rate (CAGR) of 9.9%, we can expect a corresponding evolution in the quality and functionality of CNC lathe parts.

Additionally, the growth of adjacent industries, such as 3D printing, will further influence CNC lathe technology. The 3D printing sector is projected to exceed $40 billion by 2030, highlighting the increasing adoption of additive manufacturing processes in traditional machining environments. This convergence of technologies will enhance the precision and personalization of CNC lathe parts, driving manufacturers to innovate and adapt to the shifting market demands. Furthermore, as the CNC router machine market is also expected to grow, reaching $691 million in 2023 with a CAGR of 3.5% through 2030, the overall landscape for CNC machining solutions will become increasingly competitive and diverse.

Comparative Analysis of Top CNC Lathe Part Brands: Performance & Cost

In recent years, the CNC lathe parts market has seen significant advancements, accompanied by notable shifts in performance and cost dynamics. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow from $76 billion in 2020 to $102 billion by 2026, highlighting a robust demand for high-quality lathe components. This growth is driven by the increasing need for precision manufacturing in sectors such as aerospace, automotive, and medical devices. Brands like Haas Automation and Mazak have consistently been recognized for their superior quality, leveraging precision engineering and innovative features to boost overall performance, often achieving efficiencies upward of 30% compared to competitors.

When conducting a comparative analysis of top CNC lathe part brands, one must also delve into the cost versus performance ratio. Research by Technavio indicates that while premium brands may command higher upfront costs—ranging from 15% to 25% more than lower-end options—their longevity and reduced maintenance expenses often justify the investment over time. For example, brands such as Okuma and DMG Mori not only offer enhanced functionalities but also come equipped with longer service intervals, resulting in lower total cost of ownership. As manufacturers continue to prioritize operational efficiency and cost-effectiveness, the emphasis on selecting the right CNC lathe parts will become increasingly critical.

Sustainability Trends in CNC Lathe Parts: Eco-friendly Materials and Practices

As the manufacturing industry evolves, sustainability has become a core focus, especially in the production of CNC lathe parts. In 2025, eco-friendly materials will play a pivotal role in shaping manufacturing practices. Innovations in biodegradable polymers and recycled metals are leading the charge, reducing the carbon footprint associated with traditional manufacturing processes. These materials not only decrease waste but also enhance the overall sustainability of the products, resonating with environmentally-conscious consumers and industries alike.

In addition to material improvements, companies are adopting greener practices throughout their production chains. Energy-efficient machinery and processes are being prioritized, minimizing energy consumption and promoting a reduction in greenhouse gas emissions. Furthermore, manufacturers are investing in closed-loop systems that emphasize reusability and recycling. This shift towards sustainability not only benefits the environment but also often leads to cost savings in production, making it a win-win scenario for businesses and the planet. As the demand for sustainable CNC lathe parts increases, those who prioritize these practices will position themselves at the forefront of the industry.