Top Strategies for Choosing the Best CNC Turning Machine for Your Business

In today's competitive manufacturing landscape, selecting the right CNC turning machine is crucial for optimizing production efficiency and ensuring product quality. According to a recent industry report, the global CNC machines market is projected to reach $100 billion by 2026, with significant contributions from high-quality manufacturers in China. This growth is driven by the increasing demand for precision-engineered components across various sectors, including aerospace, automotive, and electronics. Investing in a state-of-the-art CNC turning machine not only enhances operational capabilities but also provides a competitive edge in a rapidly evolving market. Therefore, understanding the key strategies for choosing the best CNC turning machine for your business is essential for leveraging these advancements and achieving long-term success.

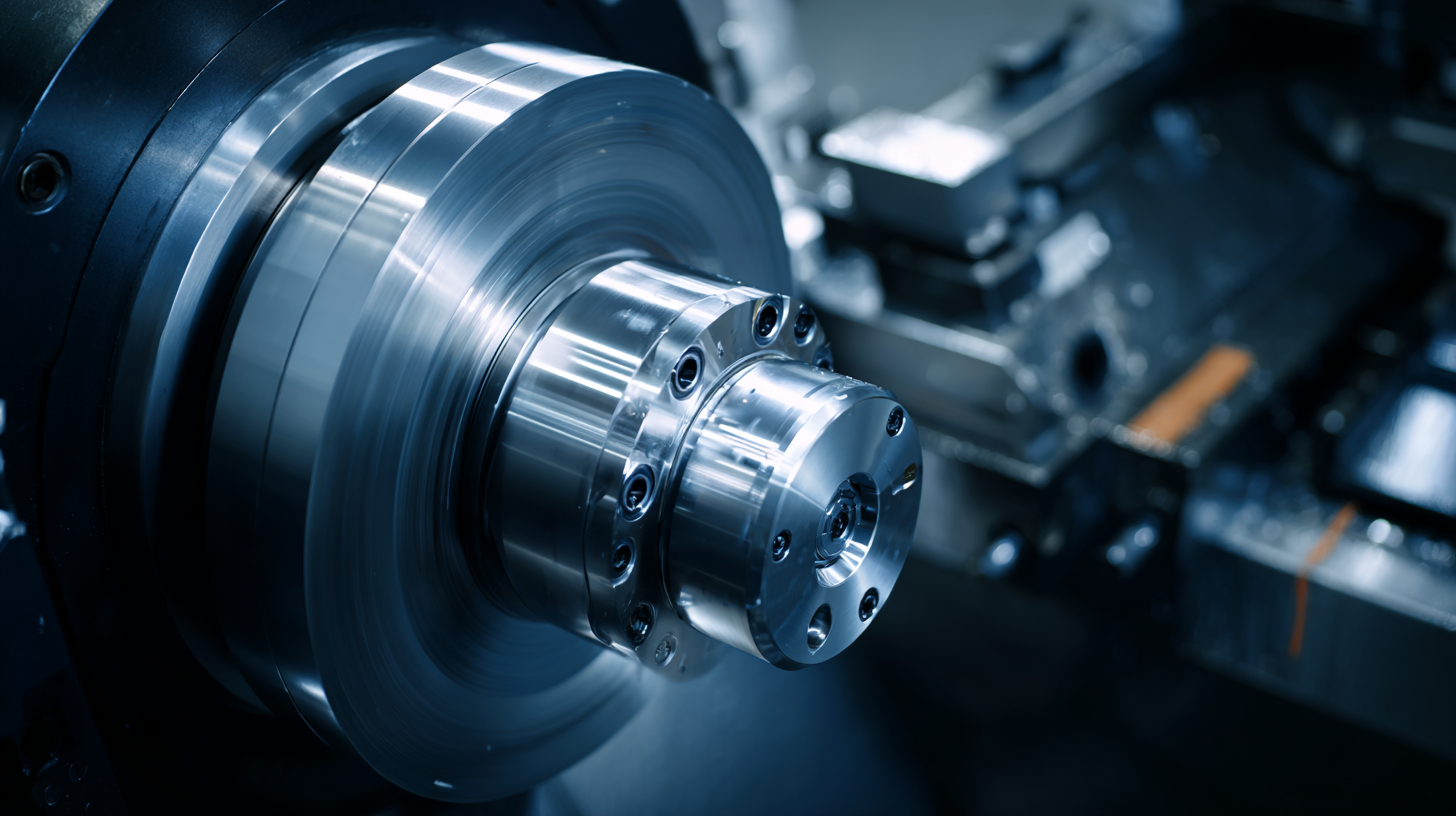

Understanding CNC Turning Machines: Key Features to Consider

When selecting a CNC turning machine for your business, understanding its key features is crucial to ensuring optimal performance and productivity. One of the most significant aspects to consider is the machine's spindle speed and torque. High spindle speeds allow for faster machining, which can enhance your overall production efficiency. Meanwhile, adequate torque is essential for managing tougher materials, providing the necessary power to maintain precision even under heavy loads. This balance is a fundamental consideration in selecting a machine that meets your specific operational demands.

Another vital feature to evaluate is the machine's control system. Modern CNC turning machines often come equipped with advanced control interfaces that offer user-friendly operations and extensive programming options. A high-quality control system enhances your capability to execute complex designs with ease, minimizing the learning curve for operators. Additionally, look for machines that support various programming languages and connectivity options, allowing for seamless integration into your existing workflow. Ensuring that the machine's control technology aligns with your production requirements will ultimately influence your business's competitive advantage.

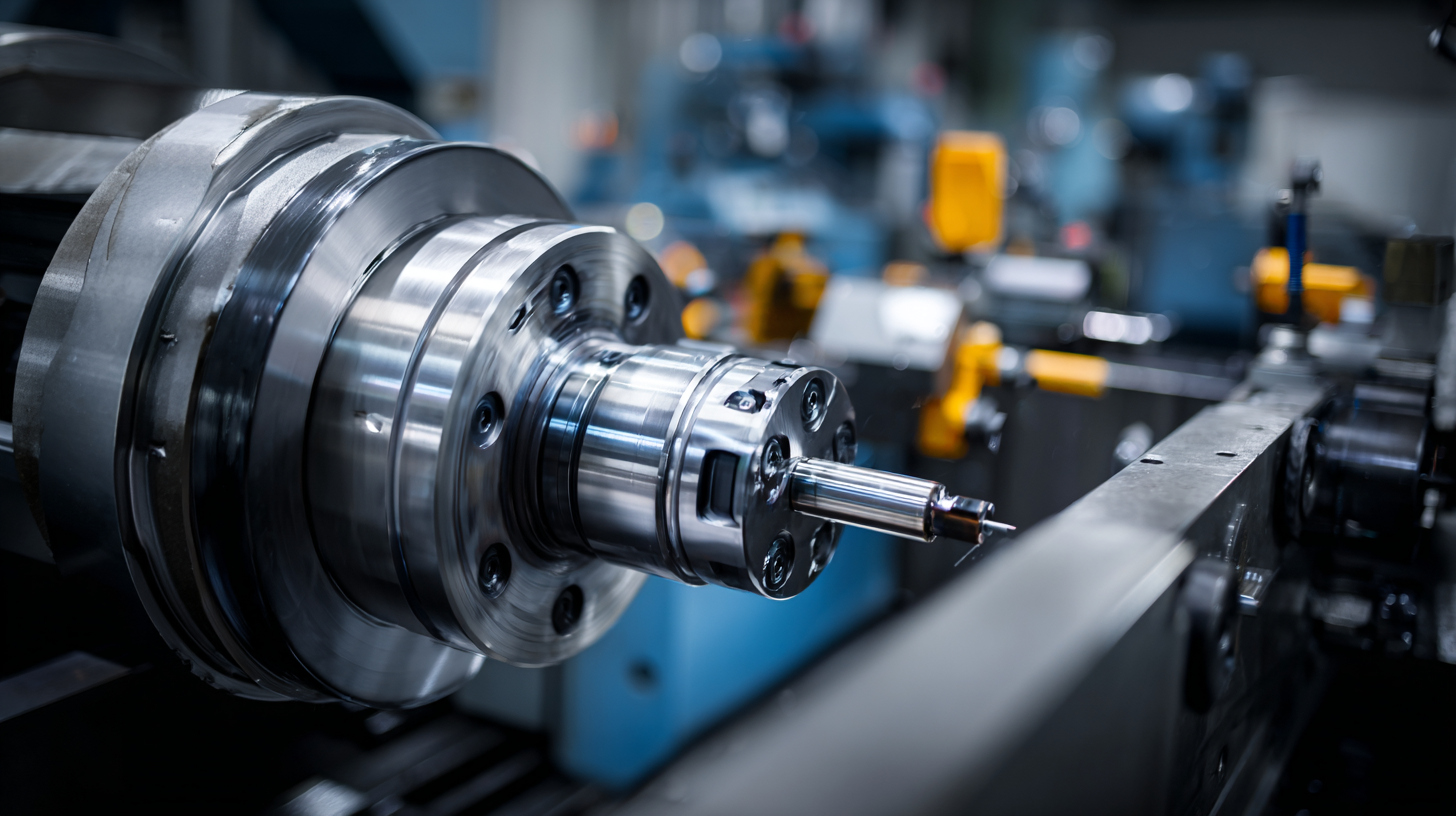

Assessing Your Business Needs for Optimal Machine Selection

When considering the purchase of a CNC turning machine, it is crucial to assess your business needs thoroughly. The first step is to evaluate the types of materials you typically work with, as different machines are optimized for varying materials, such as metals, plastics, or composites. Understanding the volume of production is also vital; a machine that can handle high volume may not be necessary if your operations are predominantly low-volume and custom jobs.

Furthermore, consider the specific features that could enhance your production capabilities. Features such as precision, speed, and automation options should align with your operational requirements. It is beneficial to identify your future needs as well, as investing in a versatile machine can help you adapt to market changes. By thoughtfully analyzing these elements, you can make an informed decision and choose a CNC turning machine that not only meets your current demands but also supports your business growth in the long run.

Top Strategies for Choosing the Best CNC Turning Machine

Navigating Industry Regulations: Import and Export Certifications Explained

When selecting a CNC turning machine for your business, understanding the complex landscape of import and export regulations is crucial. The global market for CNC machinery continues to expand, with a projected growth rate of 6.2% annually, according to a report by Markets and Markets. This growth is partly driven by rising automation demands in various industries, necessitating compliance with stringent international standards and certifications. Ensuring that your CNC turning machines meet these industry regulations not only facilitates smoother cross-border transactions but also enhances your competitive edge in the marketplace.

Import and export certifications, such as CE marking for European markets or ISO certifications, play a pivotal role in operational stability and legal compliance. Industry studies reveal that businesses with proper certifications are 30% more likely to succeed in international markets. By obtaining certifications, businesses can avoid costly delays at customs and foster trust with international clients. Moreover, keeping up-to-date with regulatory changes and obtaining all necessary documentation can significantly reduce the risks associated with non-compliance, ensuring a seamless supply chain for your CNC turning operations.

Evaluating Manufacturer Reputation and Service Support

When selecting a CNC turning machine for your business, evaluating the manufacturer's reputation and service support is crucial. A company’s standing in the industry can often provide insight into the reliability and performance of its machines. Researching customer reviews, industry ratings, and testimonials can give a clear picture of a manufacturer’s commitment to quality and customer satisfaction. Look for companies that have consistently positive feedback and have been in the market for a significant period, as this often indicates a trustworthy provider.

Equally important is the level of service support offered by the manufacturer. A CNC turning machine is a considerable investment, and having robust technical support can make a significant difference in your operational efficiency. Ensure that the manufacturer provides comprehensive after-sales support, including training, maintenance, and prompt spare parts availability. A reliable support system not only minimizes downtime but also enhances the overall performance of your machine, allowing your business to maintain productivity and competitiveness in the market.

Top Strategies for Choosing the Best CNC Turning Machine for Your Business - Evaluating Manufacturer Reputation and Service Support

| Criteria | Description | Rating (1-5) |

|---|---|---|

| Manufacturer Reputation | Researching online reviews and industry metrics to gauge the manufacturer's standing in the market. | 4 |

| Service Support | Evaluating responsiveness and quality of customer support services for troubleshooting and maintenance. | 5 |

| Warranty and Maintenance | Understanding the warranty terms and after-sales maintenance options available. | 3 |

| Technology and Innovation | Assessing the incorporation of advanced technology and innovative features in machine design. | 4 |

| Cost Effectiveness | Comparing costs with competitors and evaluating total cost of ownership over time. | 4 |

Cost-Benefit Analysis: Budgeting for Your CNC Investment

When considering the investment in a CNC turning machine, conducting a thorough cost-benefit analysis is essential. This process begins with identifying all potential expenses, which include not only the purchase price of the machine but also installation, training, maintenance, and operational costs. Understanding these figures helps businesses assess the total financial commitment and prepare for ongoing expenses that come with owning advanced machinery.

On the benefit side, CNC turning machines can significantly enhance productivity through automation and precision. By analyzing the expected return on investment (ROI), businesses can project how increased efficiency and reduced labor costs will lead to higher profit margins. For companies in industries such as aerospace or automotive manufacturing, even a minor reduction in production time can translate into substantial savings. Therefore, taking the time to evaluate both the costs and anticipated benefits provides a clearer picture of whether the CNC investment aligns with long-term business goals.