7 Best Small CNC Lathe Models for Precision Machining in 2023

In recent years, the demand for precision machining has surged, leading many hobbyists and professionals alike to seek out the best equipment for their needs. Among the various tools available on the market, the small CNC lathe stands out as an essential piece of machinery for achieving accuracy and efficiency in small-scale production. With advancements in technology, these compact lathes have become more accessible and user-friendly, making them ideal for a wide range of applications, from intricate crafting to professional engineering projects. In this blog, we will explore seven of the best small CNC lathe models available in 2023, focusing on their unique features, capabilities, and how they can enhance your machining workflow. Whether you are a seasoned machinist or just starting in the realm of CNC technology, this guide will provide valuable insights to help you choose the right small CNC lathe for your precision machining needs.

Top Features to Look for in Small CNC Lathes for Precision Machining

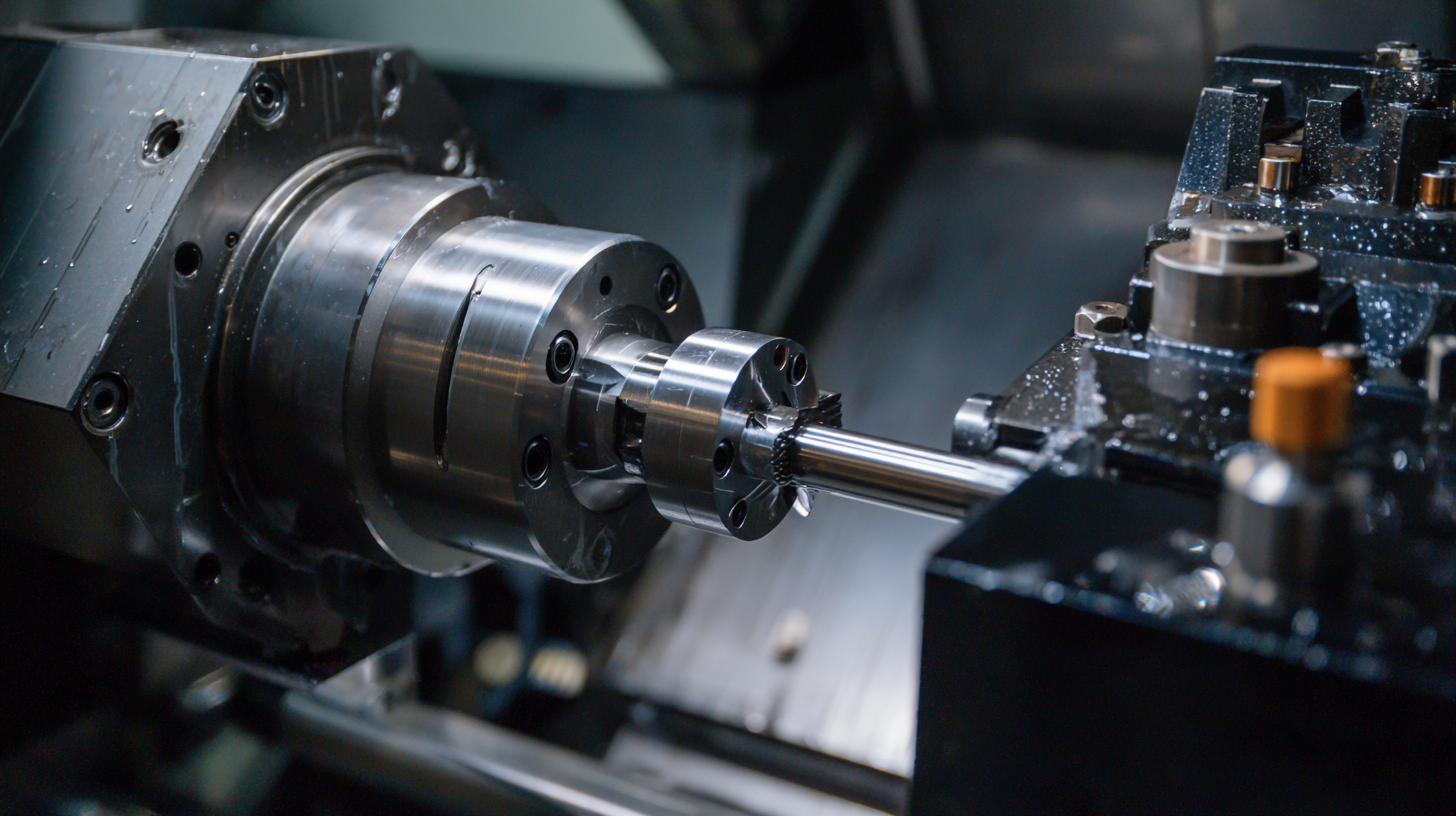

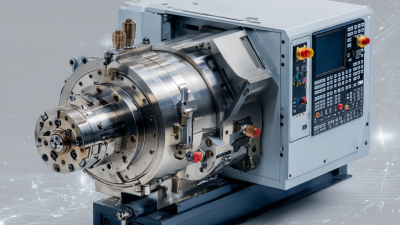

When selecting a small CNC lathe for precision machining, several key features are paramount to ensure optimal performance and reliability. First, the build quality plays a crucial role; a robust, well-engineered lathe can withstand the vibrations that occur during machining. Look for models constructed from high-grade materials such as cast iron or steel, as these tend to provide greater stability and longevity. Additionally, a well-designed bed and solid frame can enhance precision by minimizing deflection during operations.

When selecting a small CNC lathe for precision machining, several key features are paramount to ensure optimal performance and reliability. First, the build quality plays a crucial role; a robust, well-engineered lathe can withstand the vibrations that occur during machining. Look for models constructed from high-grade materials such as cast iron or steel, as these tend to provide greater stability and longevity. Additionally, a well-designed bed and solid frame can enhance precision by minimizing deflection during operations.

Another vital aspect to consider is the spindle speed and power. A lathe with a high RPM capability allows for quicker machining processes, while sufficient power ensures that the machine can handle tougher materials without stalling. Furthermore, advanced features like programmable controls and user-friendly interfaces make the machining process more efficient, allowing operators to produce intricate designs with ease. Other features such as tool change speed, coolant systems, and software compatibility can significantly enhance productivity and precision, making them essential considerations when choosing the best small CNC lathe for your needs.

Comparative Analysis of the 7 Best Small CNC Lathe Models in 2023

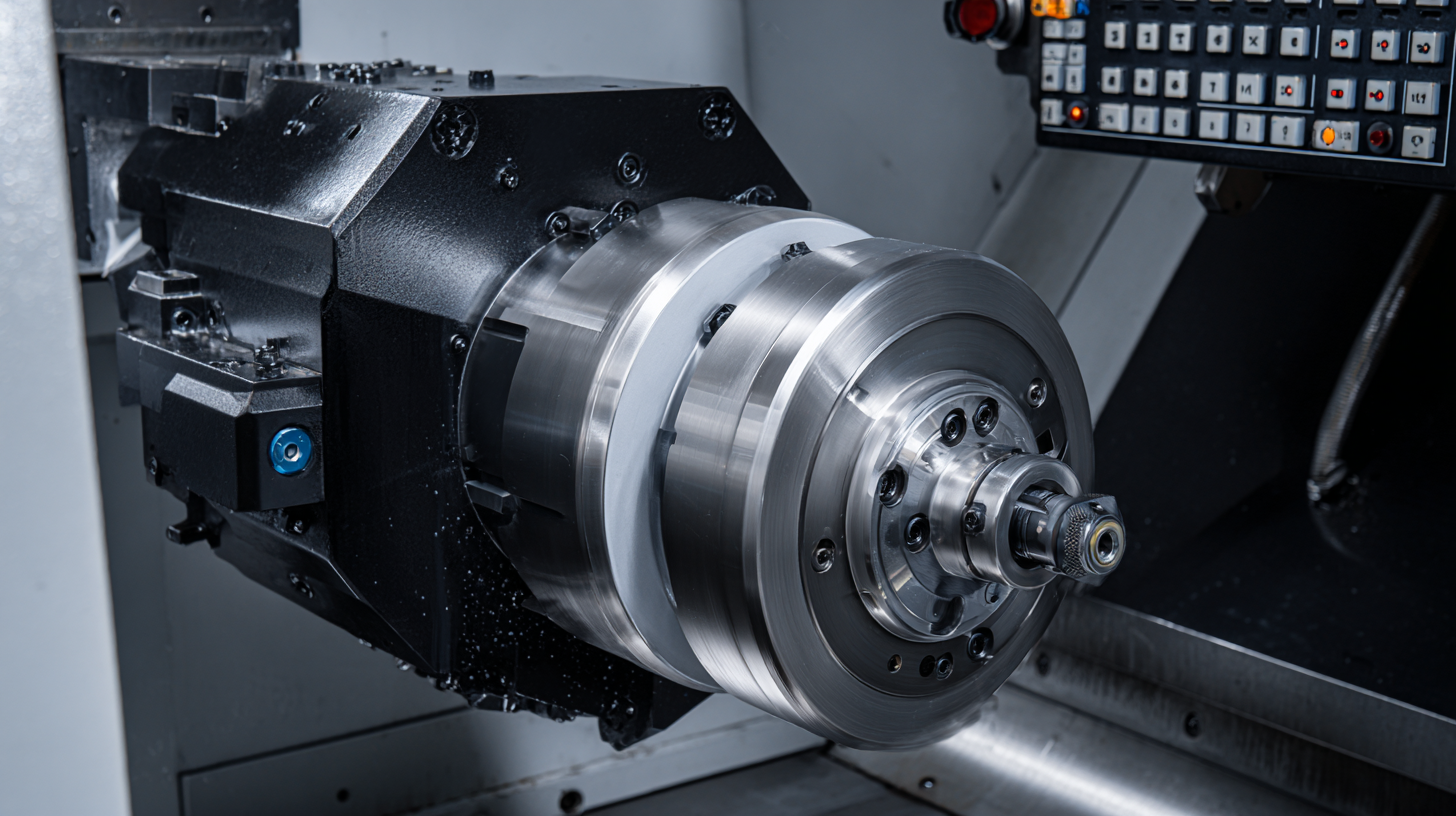

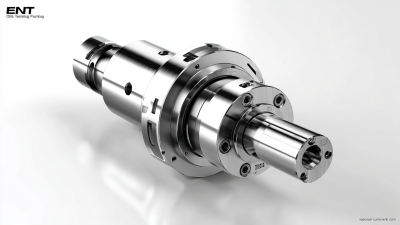

In 2023, the demand for precision machining has led to a surge in the availability of small CNC lathe models tailored for both hobbyists and professionals. This comparative analysis of the seven best small CNC lathes reveals distinct features and capabilities that set each model apart. Factors such as spindle speed, tooling options, and innovative control systems are crucial in determining the ideal lathe for various applications, whether it be intricate prototyping or small-scale production.

For instance, models like the Tormach PCNC 440 and the Sherline 4400 excel in user-friendly interfaces and adaptability, making them perfect for beginners. Meanwhile, more advanced options like the Haas TL-1 offer robust construction and higher performance for seasoned machinists. Each model’s unique specifications cater to different machining needs, from creating precise components in electronics to crafting artistic pieces in wood or metal, underscoring the versatility of small CNC lathes in modern manufacturing environments.

Cost-Effectiveness of Small CNC Lathes: Investing in Quality vs. Budget Options

When considering the purchase of a small CNC lathe, the debate between quality and budget options often takes center stage. According to the 2023 MarketWatch report, the CNC machine tool industry is poised to grow significantly, with expectations of reaching a market value of $100 billion by 2026. This growth underscores the importance of investing in high-quality machines that can deliver precision and durability, especially in an environment where competition demands excellence.

Investing in quality small CNC lathes can yield substantial returns in terms of operational efficiency and lifespan. The 2022 TechNavio survey indicates that high-quality CNC lathes can reduce machining time by up to 30% compared to their budget counterparts. While budget models may seem enticing initially, they often compromise on precision and maintenance costs. This ultimately leads to higher operational expenses and potential production delays, making a compelling case for prioritizing investment in reliable machines that can sustain a business's long-term success.

User Reviews and Performance Ratings of the Best CNC Lathe Models

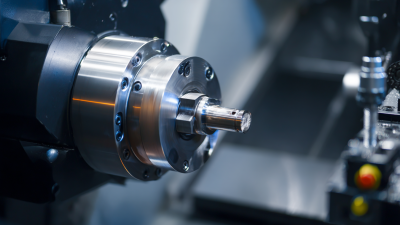

When it comes to selecting the best small CNC lathe models for precision machining in 2023, user reviews and performance ratings play a crucial role in informing prospective buyers. Customers often prioritize features such as accuracy, ease of use, and reliability. The feedback gathered from various platforms reveals that machines like the Sherline 4400 and the Fox Alien 4040-XE stand out for their exceptional precision and user-friendly interfaces. Users appreciate the high-quality components and consistent performance, making them ideal for hobbyists and professional machinists alike.

Performance ratings also highlight durability and customer support as key factors influencing satisfaction. Many users commend brands that offer extensive warranties and have responsive customer service teams, allowing for a smoother machining experience. Models like the Grizzly G0752 and the Seig X2 have garnered positive reviews for their robust construction and accessibility to replacement parts. These insights not only help in making informed decisions but also set a benchmark for manufacturers to improve upon, ultimately leading to advancements in CNC lathe technology.

7 Best Small CNC Lathe Models for Precision Machining in 2023

| Model | Spindle Speed (RPM) | Max Workpiece Diameter (mm) | Power (W) | User Rating (out of 5) |

|---|---|---|---|---|

| Model A | 2000 | 300 | 1500 | 4.5 |

| Model B | 1800 | 250 | 1200 | 4.0 |

| Model C | 2200 | 320 | 1600 | 4.7 |

| Model D | 1500 | 200 | 1000 | 3.9 |

| Model E | 2000 | 350 | 1500 | 4.6 |

| Model F | 2100 | 280 | 1400 | 4.4 |

| Model G | 1900 | 270 | 1300 | 4.3 |

Applications and Industries Benefiting from Small CNC Lathes in 2023

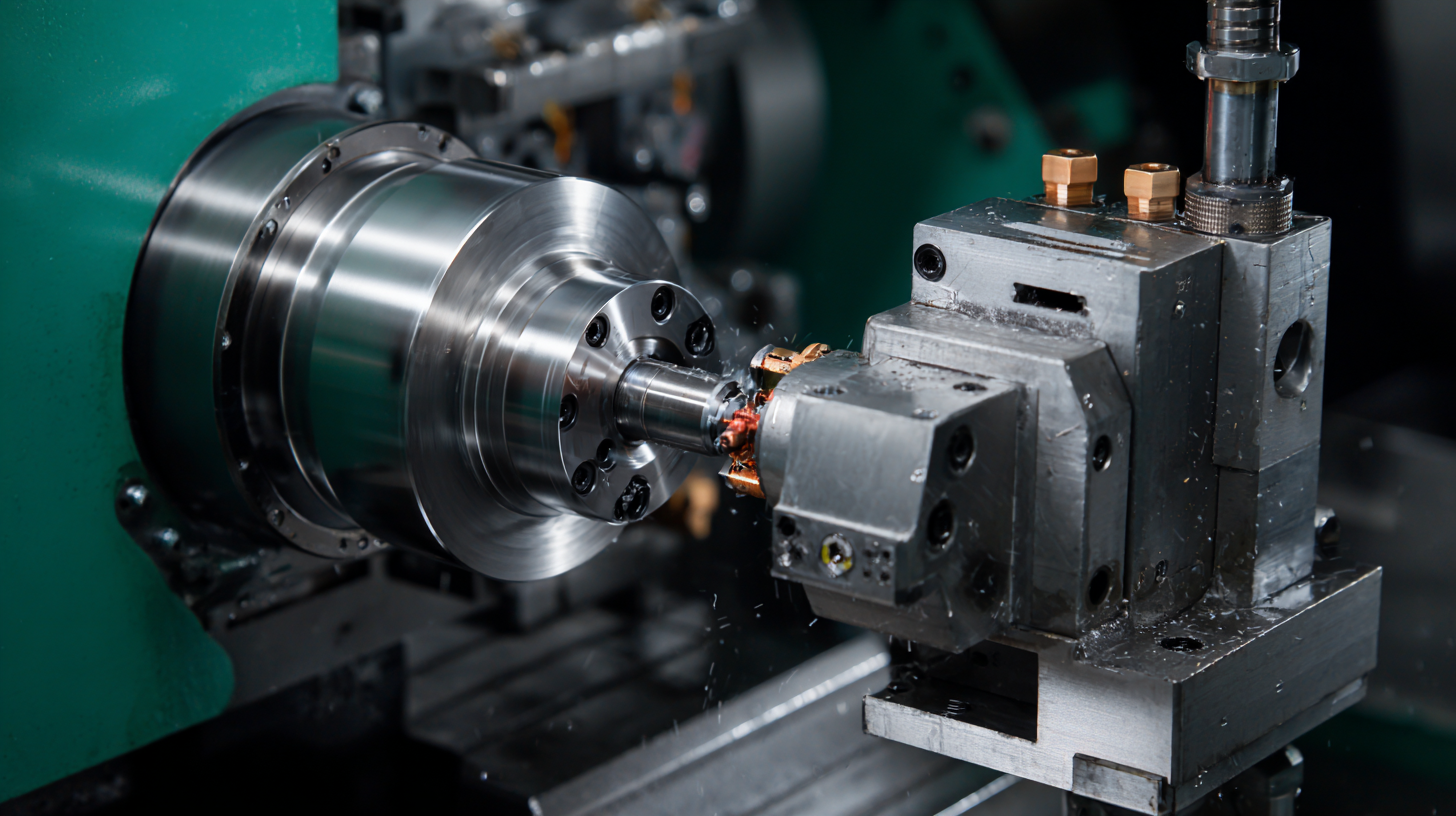

The adoption of small CNC lathes has led to remarkable enhancements in precision machining across various industries, reflecting significant growth trends in the digital manufacturing landscape. In 2023, the global CNC machines market is projected to reach an impressive $170.4 billion, a substantial increase from $66.9 billion in 2023, representing a robust CAGR of 9.80% from 2024 to 2033. This growth is largely driven by the technological advancements in CNC systems, enabling manufacturers to achieve higher efficiency and accuracy.

Industries such as aerospace, automotive, and electronics are reaping the benefits of small CNC lathes, which allow for intricate machining processes that were once labor-intensive. For instance, the precision turned product manufacturing market is anticipated to surge to $196.11 billion by 2034, highlighting the rising demand for precision components that small CNC lathes can efficiently produce.

The increased emphasis on automation and precision further underscores the growing reliance on these technologies in modern manufacturing environments, making small CNC lathes indispensable tools for achieving high-quality outputs consistently.

Related Posts

-

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

-

Market Trends for Best CNC Lathe by 2025 and the Future of Advanced Machining Technologies

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency