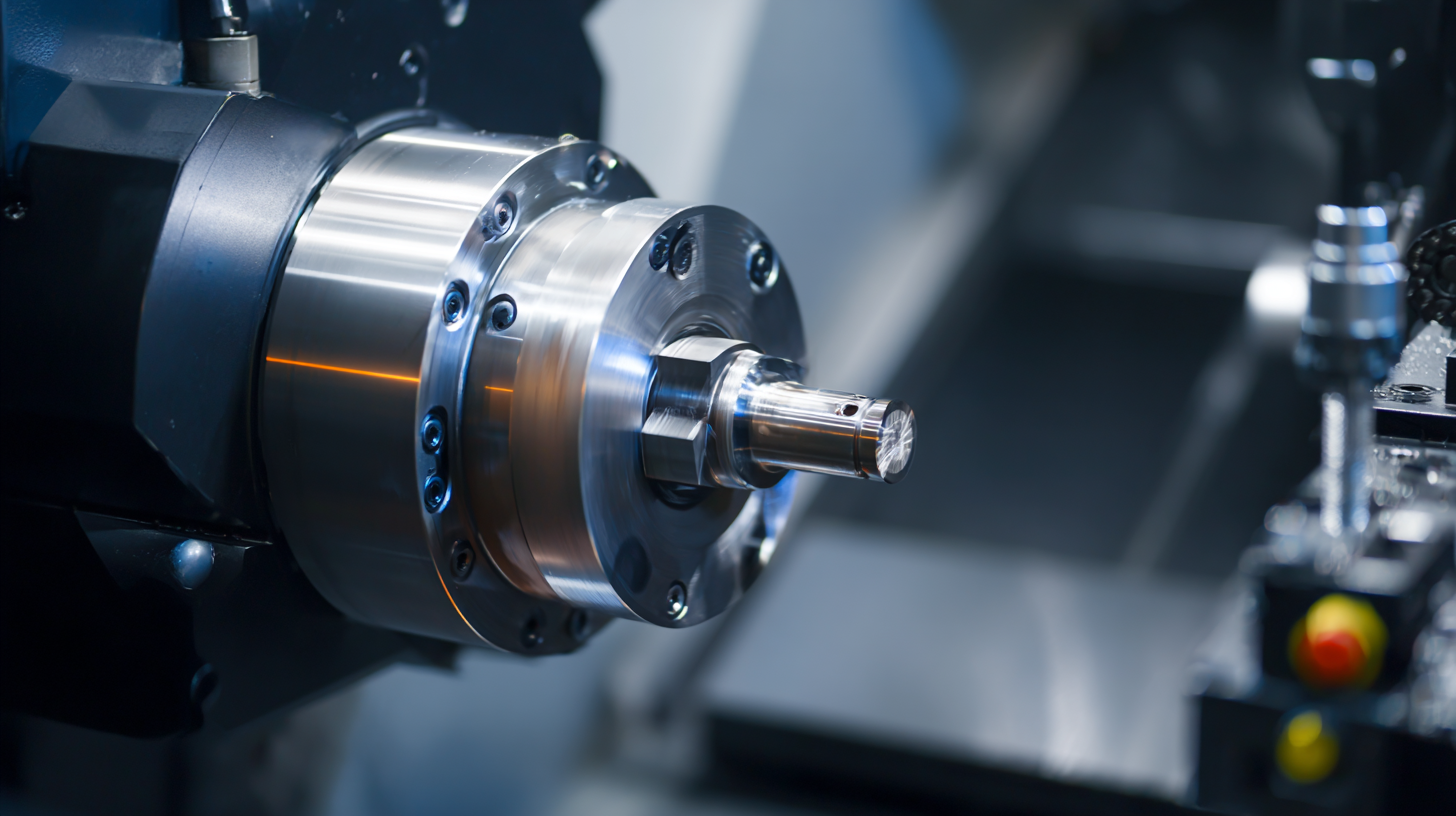

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

In today’s competitive manufacturing landscape, the integration of advanced technology is crucial for enhancing efficiency and productivity. One essential tool that has emerged as a game-changer is the small CNC lathe. According to a recent report from MarketsandMarkets, the global CNC machine market is expected to reach $117 billion by 2025, driven by the increasing demand for precision and automation in production processes. Small CNC lathes, in particular, are gaining traction among manufacturers due to their versatility, reduced footprint, and cost-effectiveness. These machines enable lean production techniques, allowing businesses to produce high-quality components with minimal waste. As Chinese manufacturing continues to focus on quality and innovation, having the best small CNC lathe can not only elevate a company's production capabilities but also enhance its competitive edge in the global export market.

Benefits of Comprehensive After-sales Support for Small CNC Lathes

After-sales support is crucial for maximizing the potential of small CNC lathes, especially in today's fast-paced manufacturing environment. As small businesses increasingly turn to CNC technology to enhance their production capabilities, having a robust after-sales support system can significantly reduce downtime and improve operational efficiency. A report from a leading industry group indicates that companies leveraging comprehensive after-sales services witness a 30% reduction in equipment downtime, enabling them to maintain a competitive edge in production schedules.

Investing in small CNC lathes with strong after-sales support also means that manufacturers can benefit from continuous training and access to the latest technology updates. For instance, subsequent integrations of cutting-edge systems, such as advanced laser technologies, can enhance precision and reduce cycle times, allowing for the production of thousands of parts weekly. It's essential to choose CNC partners who provide consistent training and technical assistance to navigate the complexities of these machines effectively.

Tip: When selecting a small CNC lathe, prioritize those that come with a guarantee of comprehensive after-sales support, including responsive customer service, maintenance services, and training programs. This will not only enhance your production capabilities but also ensure that your staff is well-equipped to utilize the machinery to its full potential.

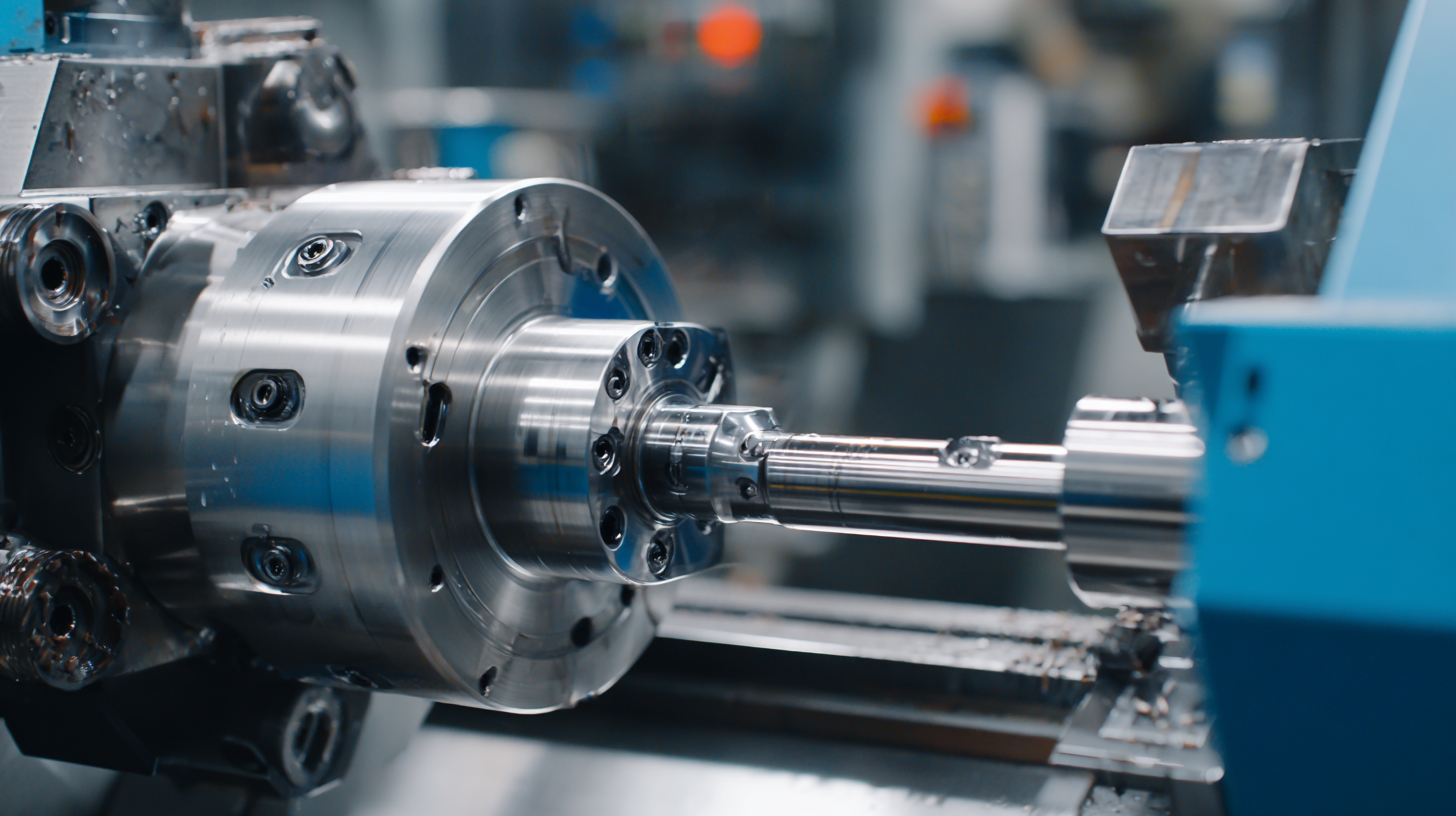

Understanding Repair Costs and Their Impact on Manufacturing Efficiency

When considering the integration of a small CNC lathe into your manufacturing process, understanding the repair costs associated with these machines is crucial. Unexpected breakdowns can lead to significant downtime, which not only disrupts production schedules but also impacts overall efficiency. By being proactive in identifying potential issues and understanding maintenance needs, manufacturers can mitigate these costs. For instance, scheduling routine inspections and adhering to recommended service intervals often result in early detection of wear and tear, preventing costly failures.

One effective tip to further reduce repair costs is to invest in proper training for your operators. Well-trained staff are more likely to recognize signs of impending issues and can adjust operations accordingly. Implementing a continuous training program ensures that your team remains up-to-date with the latest best practices, maximizing both machine performance and longevity. Additionally, tracking the performance metrics of your CNC lathe can help identify minor deviations that could signal future problems, thus allowing for timely interventions.

Finally, consider the total cost of ownership of the CNC lathe when making your purchase decision. While some machines may have a lower upfront cost, they might also come with higher maintenance and repair costs over time. It’s essential to weigh these aspects to select a lathe that not only fits your budget but also supports long-term manufacturing efficiency.

Impact of CNC Lathe on Manufacturing Efficiency

Choosing Reliable Service Providers for CNC Lathe Maintenance

When it comes to maintaining CNC lathes, selecting reliable service providers is crucial for optimizing manufacturing efficiency. The rapid advancements in computer numerical controllers (CNCs) have enhanced their capabilities, making it essential for businesses to partner with skilled technicians. Reports indicate that companies leveraging proper maintenance can see productivity increases of up to 20%. This improvement often results from reduced downtime and extended machine lifespan, demonstrating the importance of selecting experienced service teams familiar with the latest CNC advancements.

Additionally, the landscape of CNC maintenance is evolving with technology. Many service providers are now integrating digital solutions for monitoring machine health and performance. For instance, predictive maintenance technologies allow for proactive service, potentially reducing emergency repairs by 40%. As manufacturers look to improve their operational efficiency, focusing on trusted service providers that utilize modern tools and methodologies will not only streamline maintenance but also contribute to a more robust manufacturing process.

Ensuring that your CNC lathe is serviced by professionals who stay abreast of industry trends and technologies is an investment that pays dividends in operational performance.

Strategies to Minimize Downtime Through Effective Repairs

In today's manufacturing landscape, minimizing downtime is crucial for ensuring optimal efficiency, especially for businesses utilizing small CNC lathes. According to the 2023 State of Manufacturing Report, companies experience an average of 20% of their operational time lost due to equipment failures. Implementing effective repair strategies can significantly enhance production capabilities and reduce costs associated with lost time.

One effective strategy involves adopting predictive maintenance techniques. By leveraging data analytics and sensor technologies, manufacturers can forecast potential equipment failures before they occur. Research shows that predictive maintenance can reduce maintenance costs by up to 30% and improve equipment availability by 20%. This proactive approach not only extends the life of CNC lathes but also allows for more efficient scheduling of necessary repairs.

Another vital tip is to establish a comprehensive spare parts inventory. Having essential components readily available can drastically cut down repair time. An analysis by the Institute for Supply Management revealed that companies with well-stocked inventories can reduce downtime by up to 50%. By focusing on fast and effective repairs, manufacturers can maintain higher operational efficiency and effectively transform their workflows with the capabilities of small CNC lathes.

Long-term Savings: Evaluating the Cost-Effectiveness of CNC Lathes

When considering manufacturing efficiency, one of the most impactful decisions is the investment in a small CNC lathe. The cost-effectiveness of CNC lathes is not merely about their purchase price but encompasses a broader picture of long-term savings. Initially, the upfront cost might seem daunting, but the precision and reliability of CNC lathes lead to significantly reduced waste and rework time. This translates into lower material costs and a more streamlined production process, enabling businesses to meet tight deadlines and maintain high-quality standards.

Moreover, CNC lathes dramatically cut down on labor costs. With automation reducing the need for manual intervention, businesses can allocate their human resources to more strategic areas while ensuring consistent output. The ability to produce complex shapes and components with minimal human error also means fewer disruptions and faster turnaround times. Over time, these savings compound, making the CNC lathe an investment that pays for itself and the key to unlocking enhanced productivity and profitability in any manufacturing environment.

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency - Long-term Savings: Evaluating the Cost-Effectiveness of CNC Lathes

| Dimension | CNC Lathe A | CNC Lathe B | CNC Lathe C |

|---|---|---|---|

| Initial Cost ($) | 5,000 | 6,000 | 7,000 |

| Annual Maintenance Cost ($) | 300 | 350 | 400 |

| Average Downtime (hrs/year) | 50 | 40 | 30 |

| Production Efficiency (%) | 85 | 90 | 95 |

| Return on Investment (Years) | 3.5 | 3 | 2.5 |

| Projected Lifetime (Years) | 10 | 10 | 12 |

| Ease of Operation (1-10) | 8 | 9 | 10 |