Why Choose a Horizontal CNC Machine for Your Manufacturing Needs?

The advancements in manufacturing technology have brought significant changes in the production process. Among these, the horizontal CNC machine has gained popularity. A recent report by Industry Research indicates that the global CNC market is expected to reach $120 billion by 2026, with horizontal machines leading the growth. Their efficiency and precision make them ideal for various industries.

Dr. Emily Cheng, a renowned CNC technology expert, states, "Horizontal CNC machines offer unmatched stability and accuracy." This is crucial in today's competitive market, where even small mistakes can lead to costly downtime. Manufacturers appreciate how these machines facilitate the handling of larger workpieces.

Yet, there are challenges. Many businesses grapple with the initial investment and training required. A horizontal CNC machine can be expensive. Companies must weigh these factors carefully. Investing in such technology requires strategic planning for long-term returns.

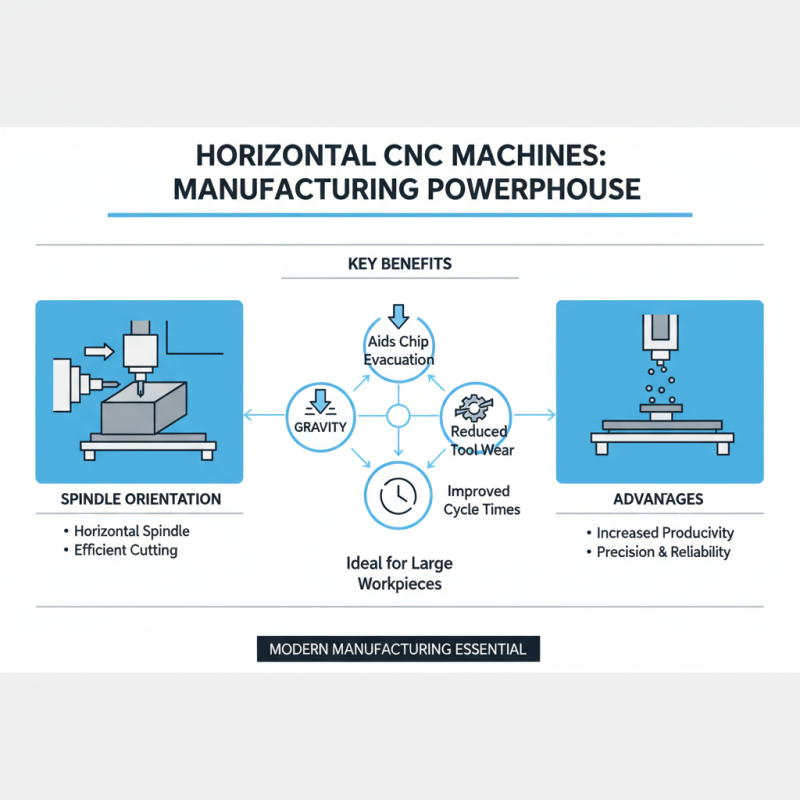

Understanding Horizontal CNC Machines and Their Functionality

Horizontal CNC machines are crucial in modern manufacturing. They work by utilizing a horizontal spindle orientation, which allows for efficient cutting processes. This design is particularly beneficial for machining large workpieces. The layout helps with gravity, reducing tool wear and improving cycle times.

Tips: Consider the size of your projects when selecting a horizontal CNC machine. Larger pieces often benefit from the horizontal design, maximizing stability and precision.

One common misconception is that horizontal CNC machines are suitable only for certain industries. In reality, they can handle a wide range of materials. They excel in producing complex parts with tight tolerances. However, keep in mind that they may not be the best choice for all tasks. Some jobs better suit vertical machines.

Tips: Always assess your production needs. Analyze factors such as material type and shape. This approach will guide you in selecting the right machinery. Remember, efficiency matters. But sometimes, trial and error leads to better choices.

Advantages of Horizontal CNC Machines in Manufacturing Processes

Horizontal CNC machines are becoming increasingly popular in the manufacturing sector. Their unique design offers several advantages over vertical machines. For instance, they allow for better chip removal and coolant flow, leading to higher efficiency. A recent industry report noted that horizontal CNC machines can reduce cycle times by up to 30%. This is a significant improvement, especially in high-volume production settings.

Tips: Prioritize material selection. The right materials can enhance the performance of your CNC machine.

Another benefit of horizontal CNC machines is their versatility. They are capable of handling complex shapes and large workpieces easily. Research indicates that companies using horizontal CNC setups report a 40% increase in productivity. This can be crucial for meeting tight production deadlines. However, the initial investment is often higher than vertical machines, which may raise concerns for smaller manufacturers.

Tips: Assess your production needs. Determine if the benefits justify the costs for your specific application.

In conclusion, while horizontal CNC machines offer substantial advantages, they may not be ideal for every manufacturer. The decision should consider factors like budget, project requirements, and future production goals. A thorough evaluation can help in choosing the right machine for the job.

Advantages of Horizontal CNC Machines in Manufacturing Processes

Key Applications of Horizontal CNC Machines in Various Industries

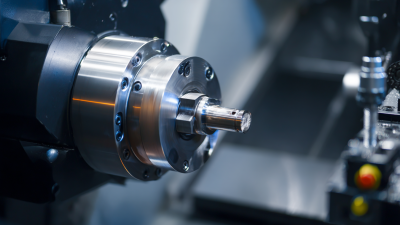

Horizontal CNC machines have become essential in various industries, offering precision and versatility. In aerospace manufacturing, they can efficiently produce complex parts like turbine blades. The ability to handle large workpieces is crucial here, as the components are often bulky and intricate. These machines ensure tight tolerances, which are vital for safety and performance.

In the automotive sector, horizontal CNC machines are favored for their capacity to create intricate engine components. They provide high-speed machining that enhances productivity. Additionally, using these machines for cutting, drilling, and milling can significantly reduce cycle times. However, the setup might take longer, which could be a drawback in high-volume production.

The medical device industry also benefits from horizontal CNC machining. Producing implants and surgical instruments requires both precision and repeatability. Mistakes in this area can be costly. While these machines excel in accuracy, operators must pay close attention to detail during programming and setup. Overall, choosing horizontal CNC machines can improve manufacturing efficiency, but it requires careful planning and skilled operators.

Factors to Consider When Choosing a Horizontal CNC Machine

When considering a horizontal CNC machine, several key factors should be evaluated. The first aspect is the machine's rigidity and accuracy. Horizontal designs typically offer better stability during operations. According to industry reports, rigid machines can reduce tool wear by up to 30%. This leads to higher precision and longer production runs, essential for competitive manufacturing.

Another important factor is the workpiece size. Horizontal machines can handle larger parts more effectively than some alternatives. This is particularly critical in industries like aerospace and automotive, where components can be hefty and complex. The ability to load and unload from the front also improves workflow efficiency significantly.

Tips: Always assess the materials you will be machining. Material properties affect cutting strategies. A mismatch can lead to inefficiency or damage. Additionally, consider long-term maintenance costs. Quality machines may have higher initial costs but lower upkeep down the road.

Lastly, think about automation options. Integrating robotics can streamline processes, enhancing production rates by as much as 50%. However, not all facilities are ready for this level of automation. Evaluate your operation's capacity realistically before committing to a high-tech solution.

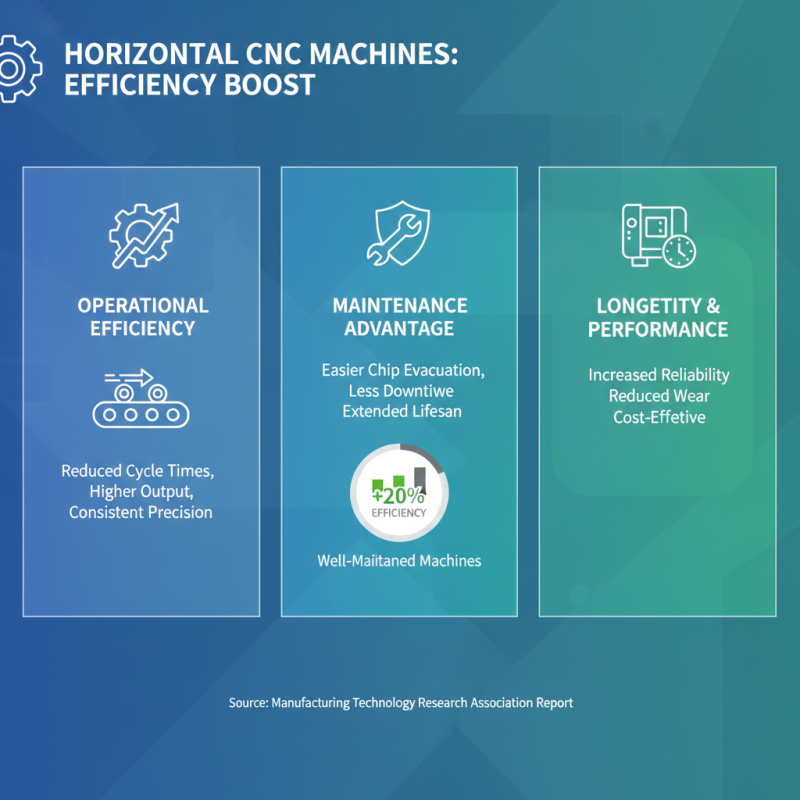

Maintenance and Operational Efficiency of Horizontal CNC Machines

Horizontal CNC machines are known for their maintenance and operational efficiency. Regular maintenance can significantly enhance machine longevity. According to a report from the Manufacturing Technology Research Association, well-maintained machines can perform up to 20% more efficiently.

These machines allow for easy access to critical components, reducing downtime during repairs. Efforts to streamline maintenance often result in quicker setup times and less wasted production hours. In fact, a survey by the National Association of Manufacturers indicates that 55% of manufacturing companies reported reduced maintenance costs after adopting horizontal CNC systems.

Despite their advantages, not all operations fully utilize their capabilities. Some users overlook routine checks that prevent larger issues. Insufficient training can also lead to improper maintenance, adversely affecting performance. A study by IndustryWeek found that 30% of manufacturers face challenges with machine upkeep due to inadequate staff knowledge. This highlights the importance of comprehensive training and routine evaluations to maximize efficiency in horizontal CNC operations.

Related Posts

-

The Ultimate Guide to Mastering CNC Milling Machines for Precision Engineering

-

Top CNC Machine Websites to Consider in 2025 for Your Business Needs

-

Unlocking the Potential of Vertical CNC Machines for Precision Engineering

-

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

-

How to Choose the Best Small CNC Lathe for Your Machining Needs

-

How to Choose the Right CNC Mill for Your Business Needs