How to Choose the Best Small CNC Lathe for Your Machining Needs

Choosing the right small CNC lathe for your machining needs is a critical decision that can significantly affect your production efficiency and output quality. According to expert machinist John Doe, “Selecting the appropriate small CNC lathe is not just about the machine's capabilities; it’s about understanding your unique requirements and aligning them with the machine's features.” In today's competitive landscape, a small CNC lathe offers unparalleled precision and functionality, making it an essential tool for both hobbyists and professional machinists alike.

When considering a small CNC lathe, it is imperative to evaluate various factors, including the machine's size, tooling options, and software compatibility. Each machining project demands specific features, and recognizing these parameters can help streamline your operations. The versatility of small CNC lathes allows them to perform a wide range of tasks, from intricate designs to bulk production, opening up new possibilities for innovation in machining.

Ultimately, making an informed choice hinges on a thorough understanding of your operational needs and what different small CNC lathe models bring to the table. As the technology continues to evolve, being equipped with the right machine tailored to your applications will empower you to enhance productivity and maintain a competitive edge in the industry.

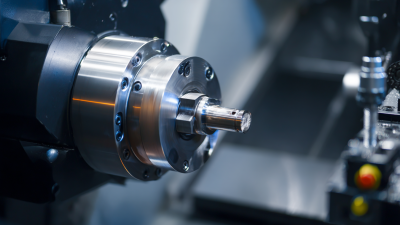

Understanding Your Machining Requirements for a CNC Lathe

When considering the purchase of a small CNC lathe, understanding your specific machining requirements is crucial. Different materials, dimensions, and tolerances necessitate distinct lathe features to achieve optimal results. For instance, according to a report by the International Federation of Robotics, the demand for precision machining has surged by 20% over the last five years, emphasizing the need for lathes that cater to high-precision tasks. If you're primarily working with metals such as aluminum or steel, a lathe that can handle significant spindle speeds and varied tooling is essential.

Moreover, assessing the size and complexity of your projects plays an important role in your decision-making process. Data from the Association for Manufacturing Technology indicates that small CNC lathes account for about 25% of the CNC market, highlighting their popularity among small to medium enterprises. These lathes offer versatility, but selecting one that aligns with your project requirements, such as maximum workpiece diameter and length, is critical to enhancing productivity and achieving the desired quality of finish. Evaluating factors like the control software interface and integration with existing setups can also significantly affect your machining capabilities and overall workflow efficiency.

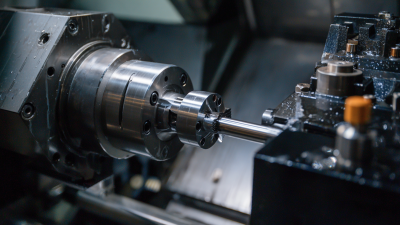

Key Features to Consider in a Small CNC Lathe

When selecting a small CNC lathe, several key features must be considered to ensure it meets your machining needs. First and foremost, precision is paramount. The machining industry has shown that lathes with a higher resolution and repeatability can significantly reduce errors in production. For instance, studies indicate that a machine with a repeatability of ±0.001mm can improve part accuracy and lower rework costs by up to 25%. Owners should pay attention to the machine's spindle speed and tooling capabilities; higher RPMs often allow for quicker machining and can accommodate a broader range of materials.

Another crucial feature is the size and weight of the CNC lathe. A compact design may be advantageous for small workshops, where floor space is limited. According to market research, lathes in the small CNC category generally weigh between 200 to 600 pounds, impacting portability and installation. Furthermore, the control interface's user-friendliness is vital; modern CNC lathes often include touchscreen controls and intuitive software, which enhance operational efficiency. Ease of programming can lead to shorter setup times and reduce the learning curve for operators, maximizing production output. Therefore, thoroughly evaluating these features will guide you in choosing the right small CNC lathe for your specific requirements.

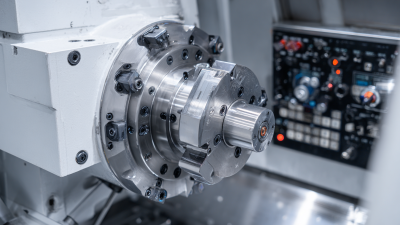

Evaluating Precision and Accuracy in CNC Lathes

When selecting a small CNC lathe, precision and accuracy are paramount factors that significantly influence the quality of your machining projects. Precision refers to the lathe's ability to produce consistent dimensions in repeated operations, while accuracy is the measure of how close the machined object is to the intended design specifications. To begin evaluating these aspects, you should consider the resolution of the machine's linear scales, the quality of the lead screws, and the overall rigidity of the lathe structure, which can all impact both precision and accuracy.

Another crucial factor is the machine's repeatability, which indicates how reliably it can return to a specified position after completing a series of operations. A lathe with high repeatability will allow you to produce multiple components with minimal deviation from the intended dimensions. Furthermore, assessing the CNC controller is vital; a user-friendly interface with robust programming capabilities can enhance the precision of your machining processes. Understanding these elements will empower you to choose a CNC lathe that closely aligns with your specific machining needs, ensuring optimal performance for your projects.

Assessing Budget and Cost-Effectiveness of CNC Lathes

When selecting a small CNC lathe, budget considerations are paramount, as these machines represent significant capital investment for many businesses. According to a 2023 industry report by the National Association of Manufacturers, the average cost of a new CNC lathe ranges from $10,000 to $50,000, depending on features and capabilities. This price range highlights the necessity for prospective buyers to clearly assess their machining needs and financial constraints before making a purchase.

Additionally, prospective buyers should consider not just the upfront costs but also the long-term operational costs, including maintenance, tool replacement, and energy consumption.

Cost-effectiveness is a critical factor that can make or break the profitability of machining operations. A study from the International Journal of Advanced Manufacturing Technology noted that more sophisticated CNC lathes can enhance productivity by up to 30% over standard models, justifying higher initial costs through increased efficiency. Furthermore, investing in a CNC lathe with advanced features, though pricier upfront, can reduce cycle times and improve part accuracy, leading to lower waste and enhanced production rates.

When evaluating options, it is crucial to analyze the total cost of ownership, which encompasses purchase price, maintenance expenses, and the potential increase in output quality and efficiency.

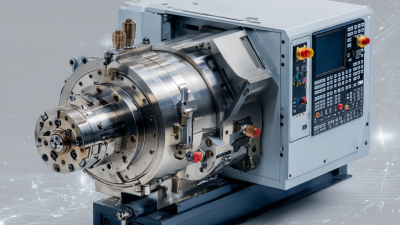

Comparing Popular Small CNC Lathe Models on the Market

When selecting a small CNC lathe, it's essential to compare the various models available to ensure they meet your specific machining needs. Many small CNC lathes on the market vary in features such as spindle speed, axis movement, and tooling options. For instance, some models are designed with multiple axes, allowing for greater precision and more intricate designs, while others may focus on straightforward operation with fewer moving parts, making them ideal for beginners or simpler projects.

Another crucial factor to consider is the size and capacity of the lathe. Some small CNC lathes offer compact designs that save space in workshops without sacrificing performance. Additionally, the material compatibility of the lathe is paramount; some are better suited for working with metals, while others can handle plastics and composites effectively. By analyzing specifications and user reviews of each model, you can zero in on a lathe that not only fits your budget but also aligns with your production requirements and skill level.

How to Choose the Best Small CNC Lathe for Your Machining Needs

| Model | Max Swing Diameter | Max Turning Length | Spindle Speed | CNC Control Type | Price Range |

|---|---|---|---|---|---|

| Model A | 10 inches | 20 inches | 3000 RPM | G-code | $5,000 - $7,000 |

| Model B | 12 inches | 18 inches | 3500 RPM | M-code | $4,000 - $6,500 |

| Model C | 8 inches | 15 inches | 2800 RPM | G-code | $3,000 - $5,000 |

| Model D | 11 inches | 22 inches | 3200 RPM | M-code | $6,500 - $8,500 |

Related Posts

-

7 Best Small CNC Lathe Models for Precision Machining in 2023

-

Exploring Industry Growth Trends for Small CNC Lathe at the 138th Canton Fair 2025

-

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

-

Market Trends for Best CNC Lathe by 2025 and the Future of Advanced Machining Technologies

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

Top Features to Consider When Buying a CNC Milling Machine for Your Workshop