Why Choose a CNC Turning Machine for Your Business Needs?

In today’s competitive manufacturing landscape, choosing the right equipment is crucial. A CNC turning machine stands out for its precision and efficiency. Dr. Emily Carter, a leading expert in CNC technology, states, “The right CNC turning machine can significantly enhance productivity while maintaining quality.”

These machines offer unparalleled accuracy, which is vital in producing complex components. For businesses aiming to optimize their operations, investing in a CNC turning machine can yield substantial benefits. The ability to automate processes leads to reduced labor costs and minimized human error.

However, the decision is not without its challenges. Integrating a CNC turning machine requires training and adaptation. Companies may struggle to fully utilize these machines without proper guidance. Reflecting on these aspects is essential for business owners. Finding the right balance between investment and operational needs is key to success.

Benefits of CNC Turning Machines for Precision Manufacturing

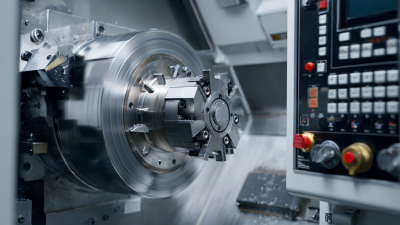

CNC turning machines have revolutionized precision manufacturing. These machines offer remarkable accuracy in shaping metal, plastic, and other materials. With a CNC turning machine, manufacturers can create complex shapes with minimal human intervention. This reduces the risk of errors, leading to better quality products.

Another major benefit is speed. CNC machines work faster than traditional methods. They allow for quick setups and rapid production runs. This means businesses can meet tight deadlines without sacrificing precision. However, the initial investment can be high. Some companies may struggle to justify this cost. It's a challenge that deserves reflection.

Efficiency is a key selling point. CNC machines can operate continuously, maximizing output. Though, maintaining these machines requires skilled technicians. Training employees can take time and resources. It's essential to weigh these factors carefully. The balance between cost, efficiency, and skill is crucial for businesses.

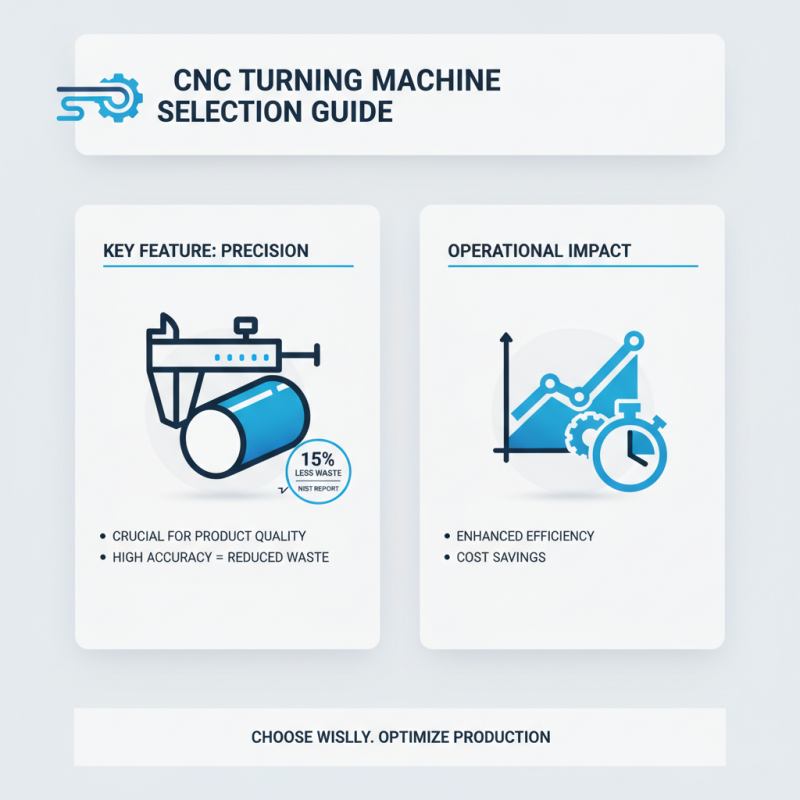

Key Features to Consider When Choosing a CNC Turning Machine

When selecting a CNC turning machine, consider several key features that can greatly impact your operations. Precision is crucial. Machines with high accuracy can enhance product quality significantly. A report from the National Institute of Standards and Technology shows that precise CNC machines reduce waste by 15%. This is a crucial consideration for manufacturers seeking efficiency.

Next, evaluate the machine's flexibility. The ability to handle various materials, such as metals and plastics, can increase your production versatility. According to a study from the Manufacturing Institute, businesses that diversify their material capabilities see a 30% increase in market access. Additionally, think about the machine's ease of use. A user-friendly interface can reduce training time by up to 40%. This also affects staff productivity, allowing for quicker adaptation to new processes.

Moreover, think about the maintenance requirements. Regular upkeep is vital for machine longevity. A lack of proper maintenance could lead to costly downtime. Reports indicate that unplanned downtime can cost manufacturers as much as $260,000 per hour. These factors require careful analysis. Balancing benefits against potential flaws is essential for making the right choice.

How CNC Turning Machines Improve Efficiency and Reduce Waste

CNC turning machines enhance efficiency and minimize waste significantly. According to a recent industry report, businesses that employ CNC technology can achieve up to 30% reduction in production time. This speed results from their ability to perform multiple tasks—turning, drilling, and milling—without manual intervention. Thus, operators can focus on quality control rather than repetitive tasks.

Tip: Regular maintenance of CNC machines is crucial. It ensures consistent performance and avoids costly downtimes.

Moreover, these machines use materials more effectively. Traditional machining often produces excess scrap, leading to higher costs. In contrast, CNC turning reduces material waste by up to 50%. This efficiency not only lowers costs but also supports environmental sustainability efforts.

Tip: Invest in software that tracks waste and efficiency metrics. Understanding your precise waste levels can guide improvement strategies.

However, adopting CNC technology comes with challenges. Initial investment can be steep, and staff training is essential. Companies may struggle with the transition. Careful planning and gradual implementation can alleviate such issues. Evaluating the specific needs of your business is key to a successful integration.

Applications of CNC Turning Machines Across Different Industries

CNC turning machines have become essential across various industries. Their precision and efficiency make them ideal for manufacturing parts. For example, in the automotive industry, nearly 30% of components are machined using CNC technology. This method allows for intricate designs that are crucial for modern vehicles.

In the aerospace sector, CNC turning is vital for producing lightweight yet durable parts. Reports indicate that about 70% of aircraft components undergo CNC machining. These parts must meet strict safety and performance standards, highlighting the importance of accuracy in manufacturing. Companies often face challenges in achieving consistent quality. Mistakes in machining can lead to significant costs.

The medical device industry also relies heavily on CNC turning. Precision is critical for devices like surgical instruments. Research suggests that around 40% of medical components are made using CNC technology. However, the process can be complicated. Many businesses need to invest in training and maintenance to ensure optimal performance. Each of these industries showcases the versatility and necessity of CNC turning machines. Yet, just adopting this technology does not guarantee success. Continuous evaluation and adaptation are essential for improvement.

Comparing CNC Turning Machines to Traditional Machining Methods

CNC turning machines stand out in modern manufacturing. They offer precision that traditional methods often lack. Unlike manual lathes, CNC machines minimize human error. Parts produced are consistent and accurate. This reliability boosts overall production quality. However, the initial setup can be complex. Operators need training to navigate these advanced systems.

In contrast, traditional machining depends heavily on human skills. Setup is faster, but maintaining precision can be challenging. Manual adjustments may lead to varying product quality. Over time, there is a risk of fatigue impacting results. CNC machines, though requiring more initial investment, pay off in the long run. They cater to high-volume production needs effectively.

Choosing between these methods is not simple. It requires assessing your specific needs and capabilities. Consider the volume of production and budget constraints. CNC machines promise efficiency and accuracy. However, don’t overlook the skill involved in traditional machining. Both options have unique strengths and weaknesses to reflect on.

Why Choose a CNC Turning Machine for Your Business Needs?

| Feature | CNC Turning Machines | Traditional Machining Methods |

|---|---|---|

| Precision | High precision, typically ±0.01mm | Lower precision, varies by method |

| Production Speed | Faster setup and production times | Slower, often longer setup times |

| Complexity of Parts | Handles complex geometries easily | Limited to simpler geometries |

| Automation | Fully automated operations available | Manual operation primarily |

| Material Versatility | Works with a wide range of materials | Material options are more restricted |

Related Posts

-

Real-World Applications of CNC Turning Centers in Diverse Industries

-

Exploring the Future of CNC Machine Tools: Innovations Driving the Next Manufacturing Revolution

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

7 Amazing CNC Machine Innovations Changing the Industry Forever

-

Top CNC Machine Websites to Consider in 2025 for Your Business Needs

-

What is CNC Turning? Understanding Application, Process, and Benefits