Unlocking Precision: How CNC Lathe Machines Revolutionize Modern Manufacturing Efficiency

In today's rapidly evolving manufacturing landscape, the adoption of cutting-edge technologies has become paramount for achieving operational efficiency and precision. Among these technological advancements, the CNC lathe machine stands out as a transformative tool, reshaping the way components are crafted across various industries. According to a report by the International Federation of Robotics, the global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for automated fabrication processes.

CNC lathe machines, in particular, have demonstrated their ability to enhance production rates and reduce waste, contributing to an overall surge in manufacturing efficiency. As manufacturers pivot towards automation and smart manufacturing practices, understanding the mechanisms behind CNC lathe technology is essential for harnessing its full potential in optimizing production workflows and driving industry competitiveness.

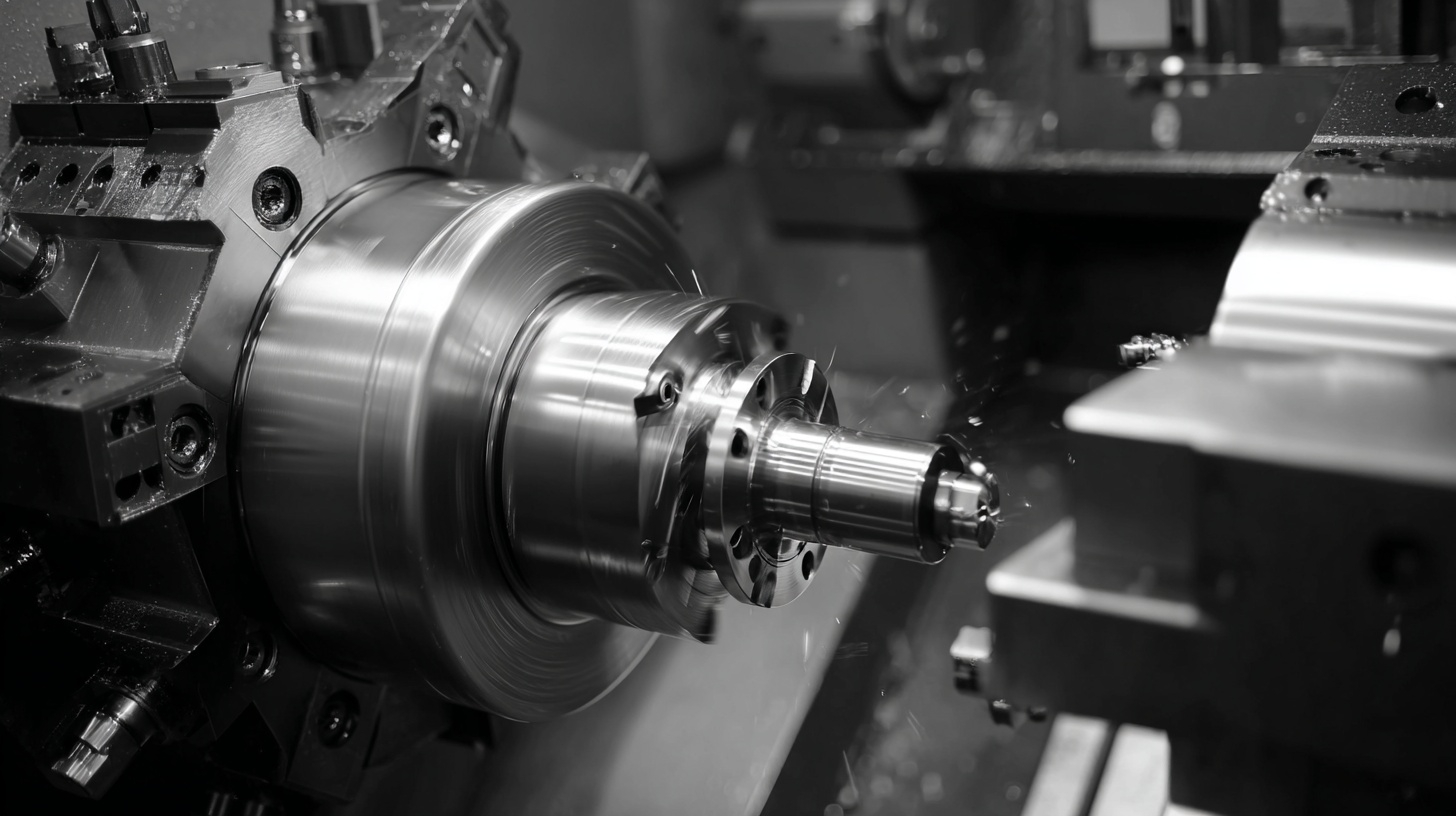

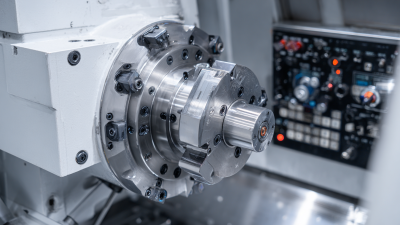

The Role of CNC Lathe Machines in Streamlining Production Processes

CNC lathe machines play a pivotal role in streamlining production processes, significantly enhancing manufacturing efficiency in various industries. One of the latest advancements in this realm is the integration of digital twin technology, which creates a virtual replica of physical CNC lathes. This innovation ensures high precision in parts production while minimizing the risk of collisions. By aligning virtual and real-time data, manufacturers can refine their operations, leading to smoother workflows and reduced downtime, ultimately increasing productivity.

Moreover, the recent surge in AI-powered CNC programming revolutionizes the way cutting files are created, allowing for faster and more accurate machining processes. As reported, the adoption of new digital manufacturing technologies has led to a remarkable increase in productivity across numerous sectors—illustrated by an impressive growth in the global metal cutting tools market, projected to reach $113 billion by 2030. With the continual evolution of automation technologies, CNC machining is becoming increasingly accessible, especially for high-mix, low-volume job shops, simplifying operations and enabling businesses to meet diverse production demands efficiently.

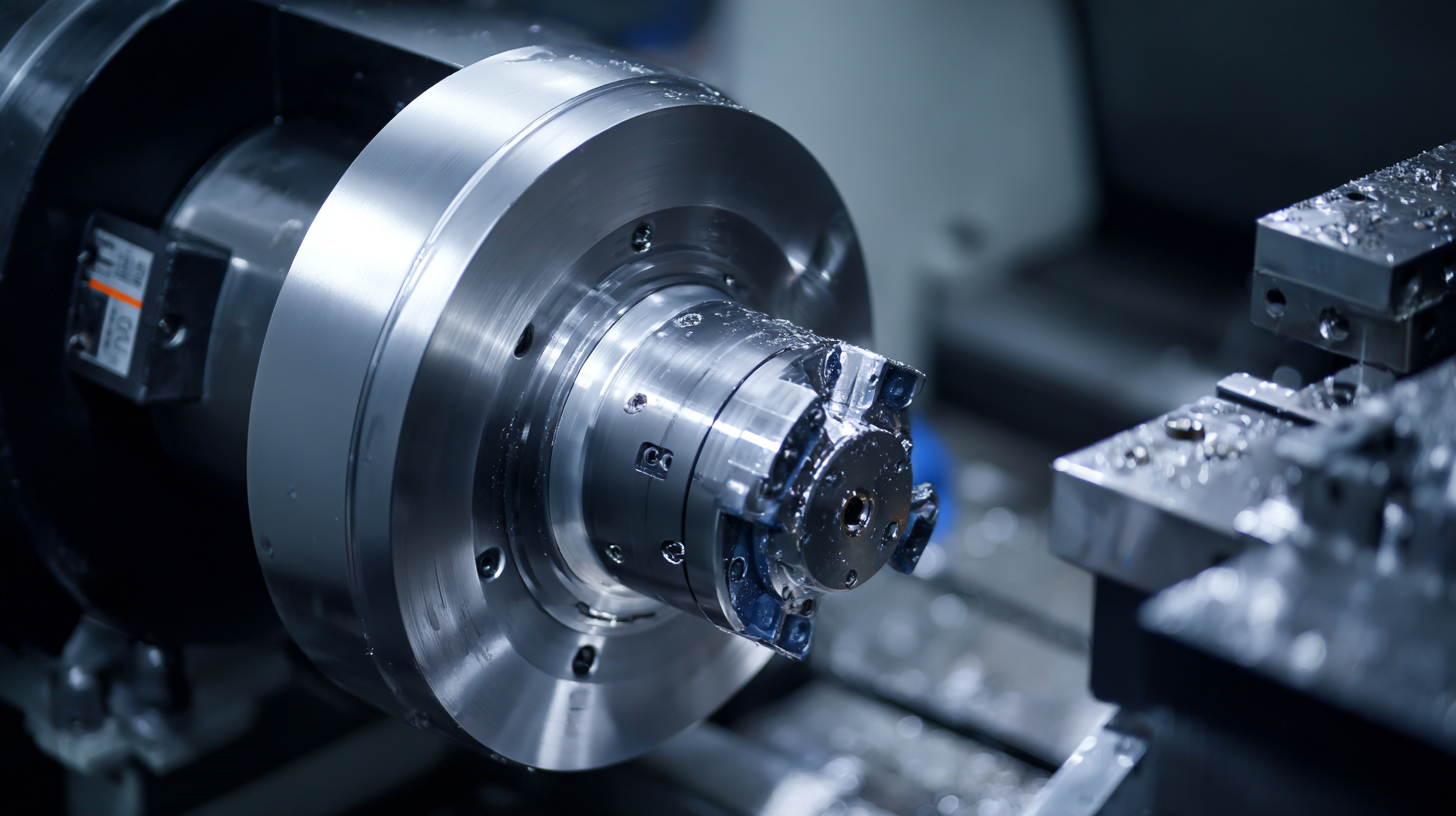

Key Aspects of Precision Engineering in Modern Manufacturing

The demand for precision in modern manufacturing has never been higher, and CNC lathe machines are at the forefront of this transformation. According to a report by Market Research Future, the global CNC machine market is projected to reach USD 100 billion by 2025, reflecting the increasing reliance on automated processes to enhance product quality and operational efficiency. CNC lathes enable manufacturers to produce intricate designs with tolerances as tight as ±0.001 inches, which is essential in industries such as aerospace, automotive, and medical devices.

One of the key aspects of precision engineering facilitated by CNC lathe machines is their ability to maintain consistency across large production runs. A study by Gardner Business Media highlighted that companies utilizing CNC technology experience a 40% reduction in lead times compared to traditional machining methods. This efficiency not only optimizes resource allocation but also elevates a company’s competitive edge in the market. As businesses continue to adopt these advanced technologies, the emphasis on precision engineering will likely redefine best practices within the manufacturing sector, driving innovation and sustainability.

Unlocking Precision: CNC Lathe Machines in Modern Manufacturing

This chart illustrates key performance metrics for CNC lathe machines, highlighting their precision, operating speed, material waste, and setup time, which are essential for improving manufacturing efficiency in modern engineering.

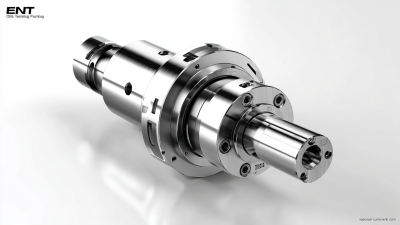

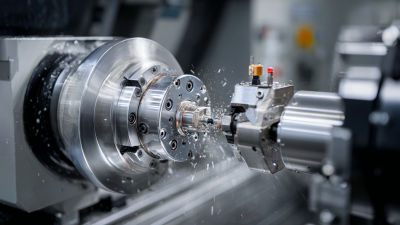

Tips for Maximizing Efficiency with CNC Lathe Technology

The advent of CNC lathe technology has marked a significant shift in manufacturing processes, enhancing efficiency and precision. According to a report by Grand View Research, the global CNC machine market is projected to reach $117.2 billion by 2027, primarily driven by the rising demand for automation across industries. To maximize efficiency when utilizing CNC lathes, manufacturers should employ several key strategies.

First, optimizing tooling and workholding setups can drastically reduce cycle times. It is essential to select the right tool materials and geometries for specific applications. A study by the American Society of Mechanical Engineers (ASME) indicates that proper tool management can improve machining time by up to 30%. Additionally, ensuring that workpieces are secured effectively not only enhances precision but also minimizes downtime caused by retooling.

Second, integrating advanced software solutions can streamline operations further. Implementing CAD/CAM software allows for precise programming and simulation, reducing errors caused by manual input. The Manufacturing Industry Trends Report by Deloitte highlights that companies adopting CAD/CAM technologies have seen productivity increases of approximately 20-25%. By leveraging these tools, manufacturers can gain a competitive edge and fully exploit the capabilities of CNC lathe machines in their production processes.

Innovative Applications of CNC Lathes in Various Industries

CNC lathe machines have become indispensable in various industries, offering innovative applications that enhance productivity and precision. In the automotive sector, CNC lathes are used to create intricate components, such as engine parts and transmission gears, which require exceptional accuracy. Meanwhile, the aerospace industry relies on these machines for manufacturing lightweight and durable components, ensuring that critical parts are produced to exact specifications while maintaining high safety standards.

Tips: When considering the integration of CNC lathes into your manufacturing process, focus on selecting the right software that optimizes machining operations. An efficient CAM (Computer-Aided Manufacturing) system can drastically reduce setup times and improve workflow efficiency.

The medical field also benefits significantly from CNC lathe technology. Precision machining allows for the creation of customized implants and surgical instruments tailored to individual patient needs. As medical advancements continue, the ability to produce complex geometries quickly and accurately is vital to enhancing patient outcomes and streamlining production processes.

Tips: Regular maintenance and calibration of CNC lathes are crucial for maintaining performance. Implementing a preventative maintenance schedule can help avoid costly downtimes and extend the life of the machinery in your production line.

Future Trends in CNC Lathe Machine Technology and Manufacturing

The evolution of CNC lathe machine technology is set to revolutionize manufacturing efficiency in the coming years. As industries increasingly adopt advanced digital manufacturing technologies, productivity gains are projected to be significant. According to industry analysts, the global market for digital readout systems is expected to grow substantially, driven by the demand for precision machining. By 2035, the market is forecasted to expand at a compound annual growth rate (CAGR) of over 7%, reflecting an ongoing shift towards automation and accuracy in manufacturing.

Moreover, the 3D printing sector is witnessing transformative trends that align with the advancements in CNC lathe technology. An executive survey of leading additive manufacturing companies revealed that 78% of respondents foresee a rise in hybrid manufacturing techniques by 2025, integrating CNC machining and 3D printing processes. This convergence enhances the capacity for rapid prototyping and reduces lead times, making manufacturing not only faster but also more versatile. The incorporation of these technologies ensures that manufacturers remain competitive while meeting diverse customer needs efficiently.

Related Posts

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

Exploring Industry Growth Trends for Small CNC Lathe at the 138th Canton Fair 2025

-

7 Amazing CNC Machine Innovations Changing the Industry Forever

-

How to Optimize Production Efficiency with CNC Turning Centers

-

Mastering CNC Milling and Turning: A Comprehensive Tutorial for Precision Manufacturing