2026 How to Use a CNC Lathe for Precision Machining Projects?

In the world of precision machining, CNC lathes stand out as transformative tools. John Smith, a renowned expert in CNC technology, once stated, “A CNC lathe is the key to achieving unmatched accuracy.” This machine allows users to create intricate designs with remarkable precision. However, mastering its use requires understanding and practice.

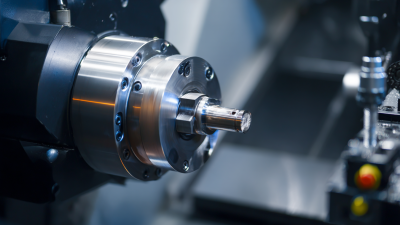

The CNC lathe operates by removing material from a rotating workpiece, shaping it into desired forms. Users can program intricate designs, making it ideal for complex projects. Yet, this process is not without its challenges. Mistakes can lead to wasted material and time. It’s crucial to pay attention to details in every step.

While the benefits of a CNC lathe are immense, there is always room for improvement. Each project provides an opportunity to learn and refine skills. Embracing these challenges can lead to better outcomes in the long run. Working with a CNC lathe can be daunting, but the precision it delivers is worth the effort.

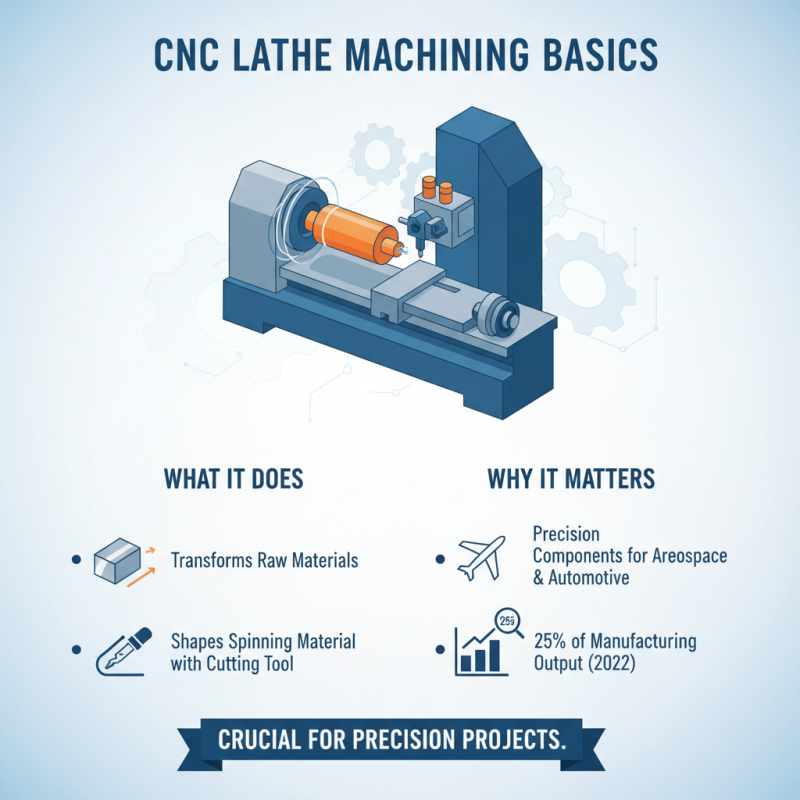

Understanding CNC Lathe Basics for Precision Machining

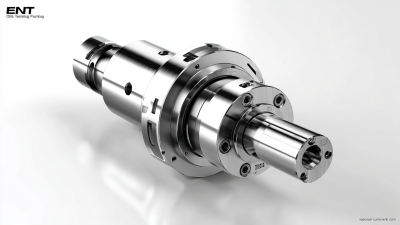

Understanding the basics of CNC lathe machining is crucial for precision projects. A CNC lathe transforms raw materials into precise components. It moves a cutting tool to shape the material as it spins. This process is essential in various industries, including aerospace and automotive. According to a 2022 industry report, CNC machining accounts for nearly 25% of manufacturing output.

Many seek to master CNC lathe operation but face challenges. The setup is not always straightforward. Knowing the right tooling and settings is vital for achieving desired tolerances. Reports indicate that a 0.001” error can significantly impact component performance. Innovating with feed rates, spindle speeds, and tool paths can yield better results. Yet, even experienced machinists can struggle with complex designs.

Practice and ongoing education are necessary. Simulation software helps visualize potential outcomes. Participants in a recent survey noted they often rely on trial and error. This method can waste time and resources. Fostering discussion within the community can lead to improved techniques. Understanding the intricacies of CNC lathes will always require ongoing reflection and adaptation.

Essential Tools and Accessories for CNC Lathe Operation

When setting up for precision machining projects with a CNC lathe, access to essential tools and accessories is crucial. A report from the Manufacturing Technology Association highlights that over 80% of successful machinists utilize advanced measuring tools. These include calipers, micrometers, and gauges, which help ensure dimensional accuracy in parts production. Measurement errors can lead to project delays and increased material waste.

In addition, consider tooling options like high-speed steel or carbide inserts. According to industry research, carbide tools provide a longer lifespan and maintain sharper edges for a more consistent finish. Using quality tool holders and fixtures allows for stable workpiece clamping. This stability helps reduce vibrations, leading to finer detail and better surface finishes.

However, some machinists overlook the importance of regular maintenance. Neglecting to calibrate or clean tools can affect performance. In fact, a study shows that regular maintenance can enhance the accuracy of CNC operations by up to 15%. So, while investing in tools is essential, ongoing care is equally important for achieving precision in machining tasks.

Step-by-Step Process of Setting Up a CNC Lathe

Setting up a CNC lathe requires precision and careful planning. Begin by ensuring your workspace is clean and well-organized. A clutter-free area promotes safety and efficiency. Gather all necessary tools, including measuring instruments and tooling. Accuracy is crucial in CNC machining. Studies show that a well-set machine can improve output quality by up to 30%.

Next, install the CNC lathe according to the manufacturer’s guidelines. Check the levels and ensure rigidity. A poorly aligned lathe can lead to vibration and affect the final product. Industry reports indicate that 25% of machining errors come from setup issues. Regularly calibrate your machine after installation. It's vital to define machining parameters correctly. Monitor RPM and feed rates to avoid material waste.

Finally, conduct a test run on scrap material. Observe the results closely. Look for inconsistencies that might call for adjustments. Errors made during setup can be costly. In fact, nearly 40% of project delays relate to initial setup errors. Keep a checklist handy to troubleshoot common problems during this phase. Learning from mistakes is crucial in mastering CNC lathe operations.

Key Techniques for Achieving Precision in Machining

When using a CNC lathe for precision machining, accuracy is paramount. To achieve this, operators must focus on key techniques. Proper tool selection is critical. Choosing the right materials for tools can enhance precision. Studies show that using carbide inserts can improve surface finish by up to 40%. Maintaining a sharp cutting edge also reduces friction, leading to a smoother operation.

Additionally, setting the correct speed and feed rates is vital. The right combination minimizes chatter, which can disrupt the machining process. According to industry reports, optimizing feed rates can enhance productivity by 25%. It’s essential to regularly evaluate these settings based on material and desired outcome. Experimenting with slightly varied parameters can lead to insights on performance improvements.

Operators often overlook the importance of regular maintenance. A well-maintained CNC lathe performs consistently better. Neglecting wear and tear can lead to inaccuracies. It might seem tedious, but routines can prevent issues down the line. Operators should implement checklists to help remember these crucial maintenance tasks. Regular reflections on machining practices could lead to improved outcomes and higher precision.

Common Challenges in CNC Lathe Projects and Solutions

CNC lathe projects present various challenges that can impact precision machining outcomes. One common issue is the calibration of the machine. Data from industry reports show that nearly 30% of machining errors stem from incorrect calibration. Regular checks and adjustments are essential to ensure that the machine operates within specified tolerances. Ignoring calibration leads to defects in the final product, which can be costly.

Tool wear is another significant challenge. Studies indicate that tools can degrade by up to 50% over time, affecting the quality of the machined parts. A systematic approach to monitoring tool conditions helps. Replacing worn tools on time not only improves precision but also reduces material waste.

Operators may face difficulties with workpiece setup. Poor setup results in misalignment, leading to inaccuracies. Data suggests that approximately 15% of projects encounter alignment issues. Investing time in proper setup techniques and using reliable fixtures can minimize these risks. Despite these challenges, the pursuit of precision machining through CNC lathes offers a path to innovation and efficiency.

2026 How to Use a CNC Lathe for Precision Machining Projects? - Common Challenges in CNC Lathe Projects and Solutions

| Challenge | Description | Common Solution | Prevention Tips |

|---|---|---|---|

| Tool Wear | Deterioration of tool sharpness resulting in poor surface finish. | Regular tool inspection and replacement. | Use optimal cutting speeds and feeds. |

| Vibration | Unwanted oscillations leading to inaccuracies. | Install dampening systems or change cutting parameters. | Ensure proper machine setup and part clamping. |

| Chip Removal | Accumulation of chips can cause blockages and faults. | Use efficient chip removal systems. | Regular cleaning and maintenance of the machine. |

| Dimensional Accuracy | Parts may not meet specified tolerances. | Frequent calibration of the CNC lathe. | Monitor the machine's performance regularly. |

| Surface Finish | Poor finish quality affecting end product. | Adjust cutting tool geometry and settings. | Select appropriate materials and coatings for tools. |

Related Posts

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

-

Unlocking Precision: How CNC Lathe Machines Revolutionize Modern Manufacturing Efficiency

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Unlocking Precision: The Impact of CNC Machine Tools on Manufacturing Efficiency in 2023

-

Discover the Excellence of Quality China Made CNC Machine Tools for Global Markets