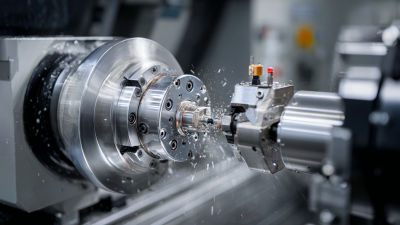

7 Amazing CNC Machine Innovations Changing the Industry Forever

The CNC machine industry is undergoing a remarkable transformation, driven by innovations that enhance efficiency, precision, and versatility. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, growing at a CAGR of 6.3%. This growth is fueled by advances in automation, artificial intelligence, and material science, which are redefining how manufacturers approach production.

The integration of smart technologies into CNC machines not only optimizes manufacturing processes but also enables real-time monitoring and predictive maintenance, significantly reducing downtime. As the demand for customized production increases, these advancements are making CNC machines more essential in various sectors, from aerospace to healthcare. In this blog, we will explore seven groundbreaking CNC machine innovations that are not only changing the industry today but are also poised to shape its future indefinitely.

Revolutionary Advancements in CNC Machining Technology

In recent years, the landscape of CNC machining technology has undergone revolutionary advancements that are transforming the industry. One of the most significant innovations is the integration of artificial intelligence (AI) into CNC machines, enabling them to learn from past operations and optimize their performance in real-time. This shift not only enhances precision but also allows for predictive maintenance, minimizing downtime and improving overall efficiency. Manufacturers can now achieve greater consistency and quality in their products, setting a new standard in the machining world.

Another groundbreaking development is the rise of 3D printing capabilities within CNC processes. This hybrid technology allows manufacturers to produce complex geometries that were previously unattainable, significantly expanding design possibilities. By combining additive manufacturing with traditional subtractive methods, CNC machines can create intricate parts with reduced material waste and faster turnaround times. As these innovations continue to emerge, they pave the way for more sustainable and cost-effective practices within the industry, ultimately reshaping how products are designed and manufactured.

Integrating Artificial Intelligence for Enhanced Precision and Efficiency

The integration of artificial intelligence (AI) into CNC machining is revolutionizing the industry, paving the way for unprecedented precision and efficiency. AI algorithms can analyze vast amounts of data in real time, allowing CNC machines to make adjustments on-the-fly for optimal performance. This adaptability not only reduces production errors but also enhances the overall quality of the finished product. With AI-driven predictive analytics, manufacturers can foresee equipment failures, ensuring timely maintenance and minimizing downtime.

Moreover, AI is empowering CNC machines to learn from past operations. By utilizing historical data, these machines can identify the most efficient machining paths, reducing cycle times and minimizing waste. The incorporation of machine learning techniques enables CNC systems to continuously improve their output, fostering innovation in design and production methods. As AI technology continues to advance, the possibilities for CNC machining are limitless, setting the stage for a new era of manufacturing where precision meets unparalleled efficiency.

The Role of IoT in Smart CNC Machines and Real-Time Monitoring

The advent of the Internet of Things (IoT) has revolutionized the landscape of CNC machining, enabling smarter, more efficient operations. According to a recent report by MarketsandMarkets, the global IoT in manufacturing market is projected to grow from $29.9 billion in 2020 to $90.4 billion by 2025, highlighting the significant shift towards interconnectivity in industrial processes. Smart CNC machines equipped with IoT capabilities allow for real-time monitoring, which can drastically reduce downtime and enhance overall productivity. By gathering and analyzing data from various machine components, manufacturers can make informed decisions that lead to improved operational efficiency.

Tip: To leverage the advantages of IoT, consider investing in CNC machines that come with built-in sensors and connectivity features. This will not only streamline your production processes but also facilitate the predictive maintenance of your equipment, thus minimizing costly repairs.

Furthermore, real-time monitoring allows for better quality control and risk assessment. A report by Deloitte indicates that companies adopting IoT technologies can reduce their operational costs by 10-15%. By continuously monitoring machine performance, companies can detect issues before they escalate into serious problems, thereby ensuring the quality of the final product remains uncompromised.

Tip: Implement a user-friendly dashboard that integrates all IoT data. This will help your team quickly assess machine status and production metrics, leading to quicker decision-making and enhanced response capabilities.

7 Amazing CNC Machine Innovations Changing the Industry Forever

| Innovation | Description | Impact on Industry | Key Technology |

|---|---|---|---|

| Adaptive Machining | Machines adjust parameters in real-time for optimal results. | Increased precision and reduced waste. | IoT Sensors |

| Automated Quality Control | Continuous monitoring of product quality during production. | Fewer defects and faster troubleshooting. | Vision Systems |

| Predictive Maintenance | Forecast machine failures before they occur. | Reduced downtime and maintenance costs. | Machine Learning Algorithms |

| Remote Monitoring | Operators can check machine status from anywhere. | Enhanced flexibility and response time. | Cloud Technologies |

| Smart Tooling | Tools embedded with sensors to optimize their usage. | Improved tool life and performance. | IoT-Enabled Tools |

| Integrated Supply Chain | Real-time tracking of material and part availability. | Optimized production schedules and reduced delays. | Blockchain Technology |

| Augmented Reality (AR) Training | AR applications for training operators on CNC machines. | Faster training and improved safety. | AR Headsets and Applications |

3D Printing and CNC: A New Era of Manufacturing Synergy

The landscape of manufacturing is undergoing a remarkable transformation, driven by the combination of CNC machining and 3D printing technologies. Together, they represent a new era of manufacturing synergy, enhancing production capabilities and introducing unprecedented levels of efficiency. CNC machines excel at precision and consistency, making them ideal for creating complex geometries with tight tolerances. Meanwhile, 3D printing offers unmatched flexibility, allowing designers to produce intricate designs without the need for traditional tooling; this accelerates prototyping and reduces waste.

Integrating 3D printing with CNC machining opens the door to hybrid manufacturing processes, providing manufacturers with the best of both worlds. By initially creating parts with 3D printing, companies can rapidly prototype and test designs before moving to CNC for final production. This not only shortens lead times but also significantly lowers costs associated with material waste and manufacturing setup. As these technologies continue to evolve and integrate, the industry will witness innovative advancements that push the boundaries of design and functionality, ultimately reshaping traditional manufacturing paradigms.

7 Amazing CNC Machine Innovations Changing the Industry Forever

This bar chart illustrates the impact scores of various CNC machine innovations. Each innovation is evaluated on a scale from 0 to 100, showcasing how they are changing the manufacturing landscape and driving efficiency in production processes.

Sustainable Practices: Eco-Friendly Innovations in CNC Machinery

CNC machining has historically been associated with precision and efficiency, but the latest innovations are steering the industry towards sustainability. Eco-friendly practices are becoming crucial as manufacturers seek to minimize their environmental impact. One of the groundbreaking advancements is the integration of biodegradable materials in CNC processes. These materials not only reduce waste but also contribute to a circular economy, ensuring that products can be repurposed or decomposed without harming the planet.

Another significant innovation is the use of energy-efficient CNC machinery. These machines are designed to consume less power while maintaining high productivity levels, significantly lowering the carbon footprint of manufacturing operations. Coupled with advanced software solutions that optimize tool paths and reduce material waste, this approach exemplifies how technology can align with sustainable practices. As the industry continues to evolve, these eco-friendly innovations not only enhance operational efficiency but also pave the way for a greener future in CNC machining, proving that sustainability and productivity can go hand in hand.

Related Posts

-

What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency

-

How to Optimize Production Efficiency with CNC Turning Centers

-

How to Choose the Best Multi Axis CNC Machine for Your Manufacturing Needs

-

Mastering CNC Milling and Turning: A Comprehensive Tutorial for Precision Manufacturing

-

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering

-

Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers