Top CNC Machine Websites to Consider in 2025 for Your Business Needs

As the manufacturing landscape continues to evolve, the demand for precision and efficiency in production processes has never been more critical. In this context, the role of a reliable CNC machine website cannot be overstated. These platforms serve as vital resources for businesses seeking to procure advanced machinery that meets their operational needs while staying ahead of technological trends. In 2025, the importance of selecting the right CNC machine website will be paramount, as companies aim to adapt to the rapidly changing market dynamics.

Navigating through a plethora of CNC machine websites can be overwhelming, yet understanding the key features and services these platforms offer can significantly influence the success of a business's manufacturing capabilities. From comprehensive product catalogs to user-friendly interfaces and customer support options, the right CNC machine website can streamline the decision-making process for manufacturers. As we move forward into a new era of production, this guide will highlight the essential aspects to consider when evaluating CNC machine websites to ensure that your business is equipped to thrive in an increasingly competitive environment.

Top Features to Look for in CNC Machine Websites in 2025

When exploring CNC machine websites in 2025, it's crucial to prioritize specific features that can significantly enhance your business operations. Firstly, a user-friendly interface is essential. Navigating a website that is intuitively designed allows potential customers to find necessary information about products and services seamlessly. This includes clear categorization of different CNC machines, as well as detailed specifications and comparisons, enabling informed decision-making.

Additionally, robust technical support and resource offerings are key features to look for. Websites should provide comprehensive product manuals, troubleshooting guides, and access to customer support representatives via chat or email. Effective online support enhances user experience and fosters a sense of trust in the company’s commitment to customer satisfaction. Furthermore, educational resources such as blogs, webinars, and tutorials can help users stay informed about industry trends and best practices, creating additional value for their investment in CNC technology.

Top CNC Machine Features in 2025

This bar chart illustrates the key features that CNC machine websites should emphasize in 2025, based on their importance ratings. High precision stands out as the most crucial aspect, closely followed by user-friendly software and customer support.

Key CNC Machine Brands to Consider for Your Business Needs

When exploring CNC machines for your business needs in 2025, it's essential to focus on brands that emphasize innovation and reliability. Key players in the industry consistently invest in advanced technology to enhance precision and efficiency. They offer a variety of machine types, including mills, lathes, and multi-tasking machines, designed to accommodate diverse manufacturing processes and materials. Their commitment to quality ensures that businesses can trust their equipment to perform optimally in demanding environments.

In addition to technological advancements, leading CNC machine brands prioritize user experience and customer support. Many provide comprehensive resources such as training programs, software tools, and responsive service teams to assist businesses in maximizing their investments. This level of support can be crucial for companies looking to integrate CNC technology into their operations smoothly, allowing for seamless training and quick troubleshooting. By considering these attributes, businesses can make informed decisions that align with their operational goals and enhance their productivity in the competitive landscape of 2025.

Top CNC Machine Websites to Consider in 2025 for Your Business Needs

| Feature | Description | Rating (out of 5) | Price Range |

|---|---|---|---|

| Machine Type | 3-Axis CNC Milling Machine | 4.5 | $20,000 - $50,000 |

| Control System | Advanced CNC Control | 4.8 | $1,500 - $5,000 |

| Support & Service | 24/7 Customer Support | 4.7 | Included |

| Software | User-Friendly CAD/CAM Software | 4.6 | $2,000 - $10,000 |

| Customization | Tailored Solutions Available | 4.4 | Varies |

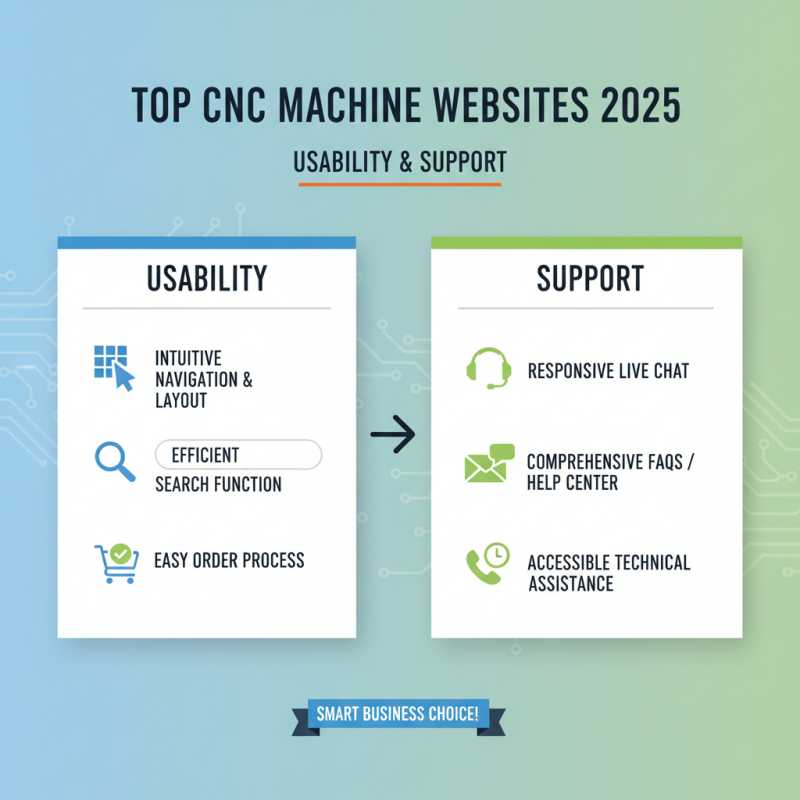

How to Evaluate CNC Machine Website Usability and Support

When considering the best CNC machine websites for your business in 2025, evaluating usability and support is crucial. A user-friendly website enhances your experience, allowing you to navigate easily, whether you are looking for product specifications or placing an order. Look for websites that have clear, logical layouts with intuitive menus and quick access to essential information. Additionally, ensure that the search function is efficient, providing accurate results without unnecessary complexity.

Tips: Prioritize websites that offer comprehensive resources, such as detailed product descriptions, technical specifications, and video tutorials. A responsive design that works well on mobile devices can also enhance usability, especially for on-the-go business owners.

Support is another vital factor. Effective customer support can make a significant difference in your purchasing journey. Check if the website provides multiple ways to reach out, such as live chat, email support, or a dedicated support center with FAQs. Additionally, consider the availability of expert advice or consultation, which can help you make informed decisions based on your specific needs.

Tips: Look for websites that offer extensive knowledge bases or community forums. This can be invaluable for troubleshooting and peer advice, contributing to a more satisfying user experience.

Comparative Analysis of CNC Machine Pricing and Performance

When evaluating CNC machines for your business in 2025, a comparative analysis of pricing and performance is crucial. The market offers a diverse range of CNC machines, each with unique specifications that can significantly impact production efficiency and operational cost. A key factor to consider is the initial investment versus the long-term benefits in terms of speed, precision, and maintenance costs. Businesses should analyze total cost ownership, which includes not just the purchase price but also the expected lifespan and potential return on investment based on production capabilities.

Additionally, performance metrics such as cutting speed, accuracy, and versatility play a vital role in optimizing production processes. It's essential to assess how different machines stack up in these areas relative to their pricing. A machine with a lower upfront cost might incur higher maintenance or operating costs, making it less attractive in the long run. Therefore, businesses should develop a comprehensive understanding of their specific production needs and incorporate these insights into their purchasing decisions, ensuring that they select a CNC machine that aligns with both their budget and operational goals.

Future Trends in CNC Technology and Their Impact on Business Decisions

As we look toward 2025, the landscape of CNC (Computer Numerical Control) technology is expected to evolve significantly, driven by advancements in automation, artificial intelligence, and materials science. A recent report from MarketsandMarkets predicts that the global CNC machine market will reach $114.69 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.1% from 2021. The integration of AI and machine learning into CNC operations will enhance precision and efficiency, leading businesses to reconsider their investment strategies in machinery to maintain competitiveness.

The implications of these trends are profound. Businesses will need to weigh the benefits of adopting cutting-edge technology against traditional methods, especially as Industry 4.0 continues to promote smart manufacturing practices. According to a survey by Deloitte, 61% of manufacturers believe that investing in smart technologies will significantly impact their operational efficiency by 2025.

This shift emphasizes the importance of staying ahead in technology options, such as adaptive machining and predictive maintenance, which not only reduce downtime but also lower operational costs. Companies that recognize and adapt to these trends will likely gain a substantial edge in the increasingly competitive market.

Related Posts

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

10 Best CNC Machine Websites for Your Precision Engineering Needs

-

Discover the Excellence of Quality China Made CNC Machine Tools for Global Markets