The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering

In the ever-evolving landscape of CNC milling and turning techniques has become essential for manufacturers seeking to enhance productivity and maintain a competitive advantage. According to a report by Grand View Research, the global CNC machining market is anticipated to reach USD 100 billion by 2026, driven by the growing demand for high-quality, precise components across various industries. CNC milling and turning not only offer unparalleled accuracy but also enable the production of complex geometries that traditional machining methods struggle to achieve.

As automation and technological advancements reshape manufacturing processes, understanding and optimizing these techniques will empower engineers and machinists to meet increasing demands with efficiency and precision. This guide aims to equip you with the insights and skills necessary to master CNC milling and turning, fostering innovation and excellence in your engineering projects.

Understanding CNC Milling vs. Turning: Key Differences in Manufacturing Processes

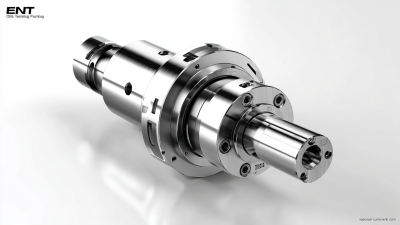

CNC milling and turning are two fundamental machining processes that serve distinct purposes in precision engineering. While both methods involve the removal of material from workpieces to achieve desired shapes, the primary difference lies in the way the material is manipulated. CNC milling employs a rotating cutting tool that moves along multiple axes to cut away material from a stationary workpiece. This technique is particularly effective for creating complex shapes, contours, and features such as grooves or pockets.

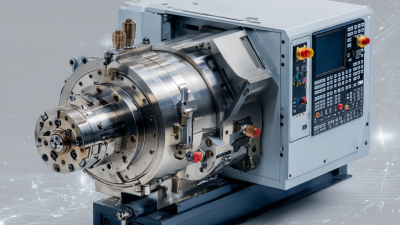

On the other hand, CNC turning involves rotating the workpiece itself while a stationary cutting tool removes material. This method is ideal for producing cylindrical parts, such as shafts, rods, and fittings. The rotational motion enables high-speed cuts and a smooth finish, making it advantageous for applications requiring tight tolerances. Understanding these key differences can help engineers and machinists choose the right process for their specific manufacturing needs, thereby optimizing production efficiency and product quality.

Precision Accuracy: Comparing Tolerance Standards in CNC Milling and Turning

In the realm of precision engineering, understanding the tolerance standards in CNC milling and CNC turning is crucial for achieving optimal results. Tolerance refers to the permissible limit of variation in a physical dimension, and it is essential in maintaining the integrity of mechanical components. When comparing the tolerance standards for CNC milling and turning, it becomes evident that each process has its unique advantages. For instance, CNC milling typically allows for tighter tolerances due to its ability to control multiple axes simultaneously, making it ideal for intricate designs and complex geometries.

On the other hand, CNC turning shines in producing cylindrical parts with high precision, especially when it comes to maintaining concentricity and surface finish. While the tolerances achievable in turning may not always match those of milling, factors such as tool wear and machine rigidity come into play. Understanding these differences allows engineers to select the appropriate machining method that aligns with the specific requirements of their projects, ultimately enhancing both efficiency and quality in production.

Material Compatibility: What Materials Are Best Suited for Milling and Turning Operations?

When it comes to CNC milling and turning operations, selecting the right materials is crucial for achieving precision and efficiency. Recent advancements in manufacturing technologies highlight the importance of material compatibility. For instance, CVD diamond processing tools have gained prominence since the 1980s due to their exceptional hardness and wear resistance, making them ideal for machining tough materials and composites. This is particularly relevant when dealing with novel materials like LM25Al/VC composite, which combines aluminum with vanadium carbide to enhance machinability. Studies reveal that using analytical modeling alongside deep learning techniques can significantly optimize machining processes for such composites, emphasizing the need for compatible tooling.

Moreover, the increasing use of composite materials in various industries further underscores the importance of material selection. A review of advances in composite applications, particularly in the automotive sector, showcases their lightweight properties and strength benefits over traditional metals. For CNC machining, materials like fiber-reinforced composites are rapidly gaining traction due to their excellent performance characteristics and versatility. As industries move towards incorporating these advanced materials, manufacturers must ensure that their CNC techniques and tools are well-suited to handle the specific demands posed by these innovative materials.

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering - Material Compatibility: What Materials Are Best Suited for Milling and Turning Operations?

| Material Type | Best Application | Machinability Rating | Typical Feed Rate (mm/min) | Cutting Speed (m/min) |

|---|---|---|---|---|

| Aluminum | Aerospace components | 90 | 200-500 | 150-300 |

| Steel | Structural parts | 60 | 100-250 | 100-200 |

| Titanium | Medical implants | 40 | 50-120 | 60-100 |

| Plastic | Consumer products | 70 | 300-600 | 80-150 |

| Copper | Electrical components | 75 | 100-300 | 150-400 |

Cost Efficiency Analysis: CNC Milling vs. Turning — Which Provides Greater ROI?

When it comes to precision engineering, choosing between CNC milling and turning is crucial for maximizing cost efficiency. CNC milling is often preferred for complex shapes and detailed features, while turning excels at producing cylindrical parts with high precision. A recent analysis shows that CNC turning typically offers a greater return on investment (ROI) due to its faster setup times and reduced material waste. Understanding the strengths of each technique can ultimately guide engineers in selecting the right process for their projects.

**Tip:** Always conduct a thorough analysis of project requirements before deciding on a machining method. By assessing factors such as part geometry, materials, and production volume, you can determine whether milling or turning will lead to lower costs and increased efficiency.

**Tip:** Consider investing in multi-axis CNC machines that can handle both milling and turning processes. This versatility not only streamlines production but can also significantly cut down on overhead costs associated with maintaining separate machines for each process.

Understanding these dynamics allows for informed decisions and better alignment with business objectives, ensuring that your engineering projects are both cost-effective and high quality.

The Cost Efficiency Analysis: CNC Milling vs. Turning

Future Trends: The Impact of Automation on CNC Milling and Turning Techniques

As automation continues to revolutionize the manufacturing landscape, CNC milling and turning techniques are experiencing profound transformations. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2025, with a significant portion of this growth driven by automation technologies. Automation not only enhances production efficiency but also improves precision, allowing manufacturers to streamline operations and reduce human error in machining processes.

The integration of advanced robotics and AI in CNC milling and turning setups offers the potential for increased adaptability in production lines. Research by McKinsey indicates that automation can lead to a productivity increase of up to 30% in manufacturing operations. By utilizing automated systems, companies can also achieve more consistent quality in their output, thereby meeting the ever-growing demand for precision engineering in various industries, such as aerospace and automotive. These trends highlight the importance of embracing cutting-edge technology to stay competitive and meet future challenges in precision engineering.

Related Posts

-

How to Optimize CNC Mill Performance for Maximum Efficiency and Precision

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

Crafting Excellence with the Best CNC Machines from China for Global Service