Top 10 CNC Milling Parts You Need for Precision Engineering Success

In the ever-evolving landscape of precision engineering, the importance of high-quality CNC milling parts cannot be overstated. As technology advances, the demand for components that not only meet stringent specifications but also enhance overall efficiency continues to rise. Renowned CNC engineering expert, Dr. Mark Thompson, emphasizes this point: "The right CNC milling parts are crucial for achieving precision and reliability in modern manufacturing processes." This insight underlines the pivotal role these components play in ensuring that engineering projects can be executed with the utmost accuracy and consistency.

As we delve into the “2025 Top 10 CNC Milling Parts You Need for Precision Engineering Success,” it becomes evident that understanding the essential elements is key to navigating the complexities of precision engineering. From custom tool holders to advanced workholding solutions, each part listed contributes significantly to the effectiveness of CNC operations. By highlighting these top components, we aim to provide engineers and manufacturers with the knowledge required to optimize their production capabilities and stay ahead in a competitive market. Whether you are a seasoned professional or a newcomer to the field, recognizing the value of quality CNC milling parts is an essential step toward engineering success.

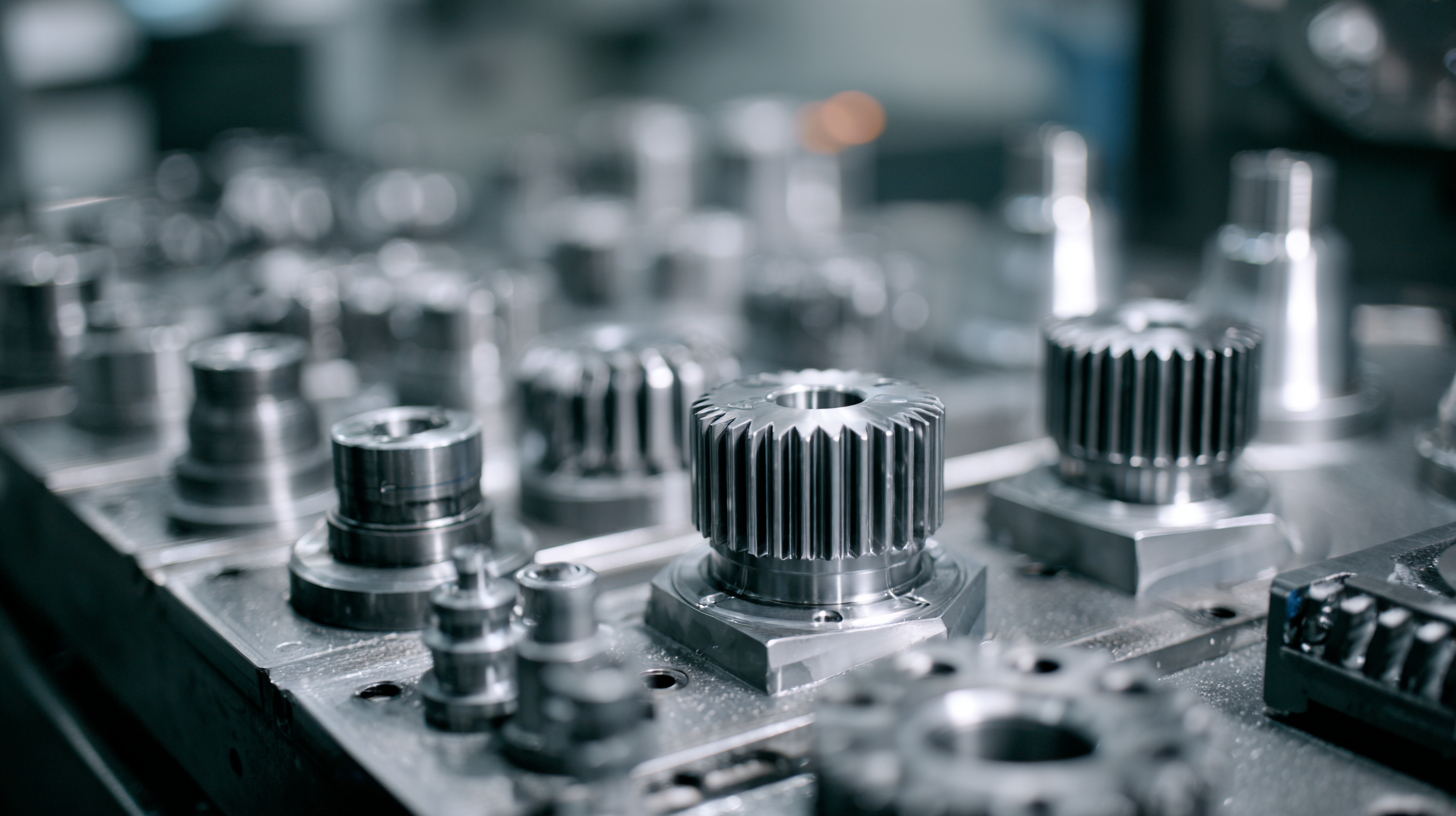

Essential CNC Milling Components for Accurate Fabrication

In precision engineering, the accuracy of fabricated components is heavily reliant on the quality of CNC milling parts. Essential elements such as spindle assemblies, toolholders, and workholding devices play a critical role in achieving tight tolerances and superior surface finishes. According to a recent industry report by MarketsandMarkets, the CNC equipment market is projected to reach $117 billion by 2027, indicating a robust expansion driven by the push for more precise manufacturing solutions.

When selecting CNC milling components, it's vital to consider materials and configurations that minimize vibration and thermal distortion. For instance, investing in high-quality toolholders made from premium alloys can enhance rigidity, resulting in more accurate machining.

Tips: Always perform regular maintenance on your tools and machines to prevent downtime and ensure optimal performance. Additionally, integrating advanced cooling systems can mitigate heat generation, further preserving the integrity of both the tool and the workpiece.

Another significant factor is the precision of the CNC machine itself. Advanced CNC systems now come equipped with real-time monitoring features that help track performance and detect anomalies early. This capability not only boosts productivity but also ensures that precision standards are consistently met.

Tips: Utilize data from machine feedback to calibrate your processes frequently, fostering an environment of continuous improvement in precision engineering.

Key Characteristics of Quality CNC Milling Parts

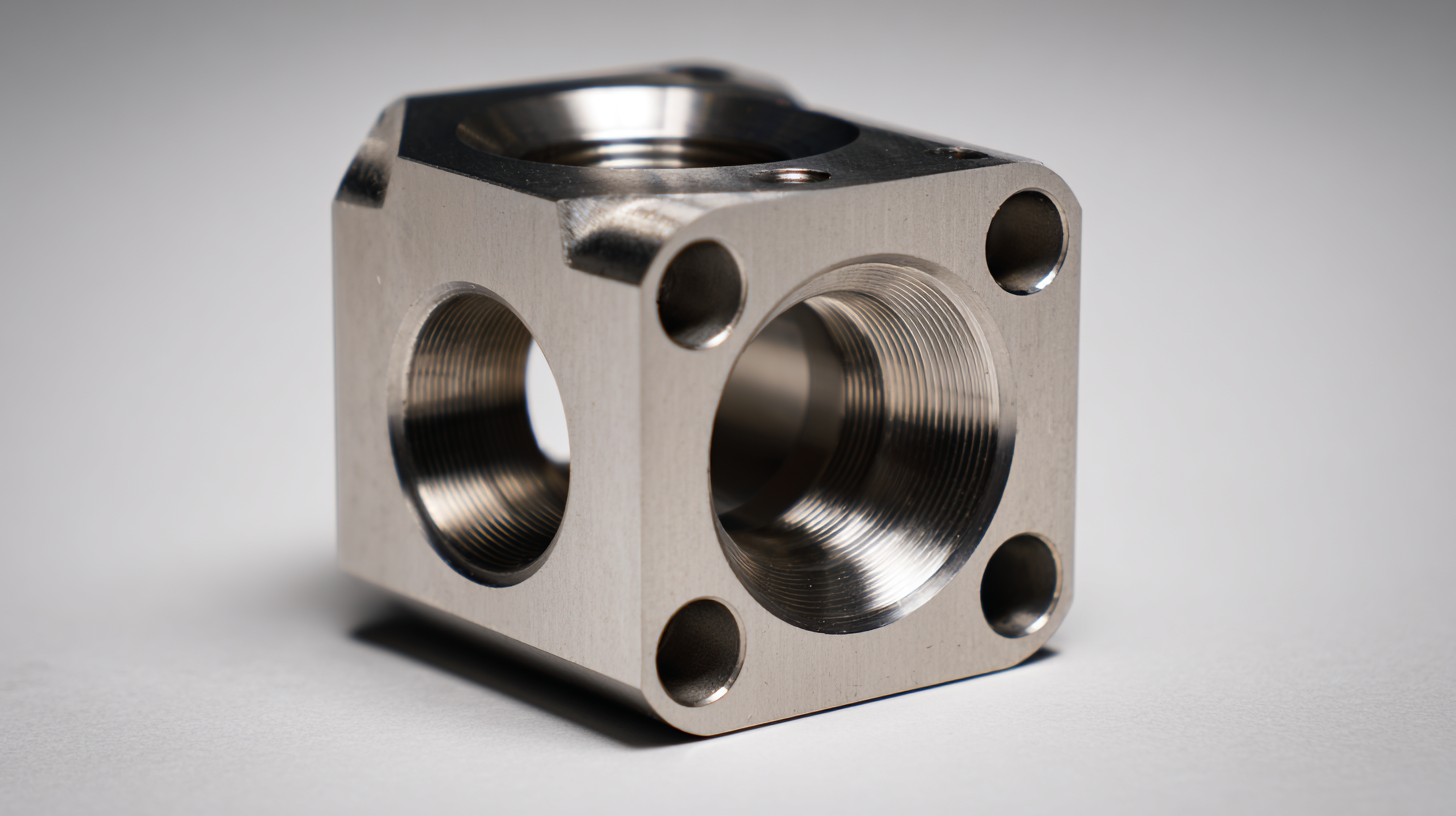

When it comes to precision engineering, the quality of CNC milling parts plays a crucial role in ensuring successful outcomes. One of the key characteristics of high-quality CNC milling parts is their material composition. The choice of materials, such as aluminum, steel, or specialty alloys, directly affects the strength, durability, and resistance to wear of the final products. Premium materials not only enhance the part’s performance but also contribute to the longevity of machinery, reducing the need for frequent replacements.

Another important factor is the precision of manufacturing processes. CNC milling parts must be fabricated with tight tolerances to meet engineering specifications. This precision is achieved through advanced machining techniques and state-of-the-art equipment, ensuring that every component fits seamlessly within larger assemblies.

Surface finish is also a significant characteristic; smooth finishes reduce friction and improve the overall efficiency of the machinery. Ultimately, the combination of high-quality materials and precise manufacturing processes distinguishes exceptional CNC milling parts, making them indispensable for any successful precision engineering endeavor.

Top CNC Materials for Enhanced Durability and Precision

In precision engineering, the choice of CNC materials plays a critical role in enhancing both durability and precision of the final products. When selecting materials for CNC milling, it is essential to consider factors such as tensile strength, machinability, and thermal stability. Steel and aluminum are often favored for their excellent structural integrity and ease of machining, making them ideal for various applications in the manufacturing industry. Additionally, composites and titanium alloys are gaining traction due to their lightweight properties and resistance to corrosion, which is vital for components subjected to harsh environments.

Tips for selecting CNC materials include identifying the specific requirements of your project, such as load-bearing capacity and environmental conditions. Always opt for high-quality materials to ensure long-lasting performance and reduced rework. It's wise to consult with suppliers who specialize in precision CNC manufacturing to gain insights into the best material options available.

As automation increases in metal forming processes, the impact on CNC milling operations is significant. Enhanced automation leads to improved production efficiency and quality consistency, allowing manufacturers to meet the rising market demands. When integrating automation into production systems, consider using advanced feeding solutions like vibratory bowls, as they significantly streamline workflows and minimize downtime in manufacturing processes.

Innovative Technologies in CNC Milling Equipment

The landscape of CNC milling is rapidly evolving with the adoption of innovative technologies that enhance productivity across various industries. As detailed in recent market studies, the global CNC machine market is projected to grow significantly, with a particular emphasis on advancements in milling machines. These innovations not only improve efficiency but also enable manufacturers to achieve higher precision in their operations, catering to the increasing demand for customized and intricate designs.

In addition, the introduction of Iran's first portable CNC milling machine signifies a major leap in industrial technology within the region. This development not only fosters self-sufficiency but also serves as a cost-saving measure, reinforcing the importance of embracing cutting-edge machinery in today's market. As manufacturers explore these advanced CNC milling solutions, they are well-positioned to enhance their production capabilities and drive industry growth.

Best Practices for Selecting CNC Milling Parts for Projects

When embarking on a precision engineering project, selecting the right CNC milling parts is crucial for achieving superior results. First and foremost, it's essential to understand the specific requirements of your project. Consider the materials you'll be working with—different materials, from aluminum to titanium, have unique machining characteristics that influence the choice of tools and parts. Additionally, the complexity of the design will dictate the precision and type of milling components you need.

Another best practice is to prioritize the compatibility of your selected CNC milling parts with your existing machinery. Ensuring that parts can seamlessly integrate with your CNC machine will minimize setup times and enhance overall efficiency. It's also wise to consult with manufacturers or experienced technicians, as they can provide valuable insights into the most effective components for your specific application. Investing time in this selection process not only fosters accuracy but also contributes to the longevity and performance of your engineering projects.

Related Posts

-

How to Optimize CNC Mill Performance for Maximum Efficiency and Precision

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

Challenges Associated with Choosing the Best CNC Milling Machine for Your Needs

-

Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers

-

Emerging Trends in CNC Vertical Machining Centers for 2025 A Comprehensive Guide

-

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering