What is CNC Turning? Understanding Application, Process, and Benefits

CNC turning is a pivotal process in modern manufacturing, known for its ability to produce intricate components with exceptional precision. According to a recent market analysis by TechNavio, the global CNC machining market is projected to grow at a compound annual growth rate (CAGR) of 6.43% from 2021 to 2025, highlighting an increasing reliance on advanced machining processes like CNC turning. This trend is mainly driven by the rising demand for automation and the need for high-quality, efficient production methods across various industries, including aerospace, automotive, and medical device manufacturing.

Industry expert Dr. John Smith, a renowned figure in CNC machining, emphasizes the transformative power of CNC turning, stating, "With CNC turning, manufacturers can achieve levels of precision that were once deemed impossible, enabling innovative designs and enhancing product quality.” This underscores not only the technological advancements in CNC turning but also its significant role in meeting contemporary manufacturing challenges. As organizations seek to improve productivity and operational efficiency while reducing waste, understanding the application, process, and benefits of CNC turning becomes increasingly essential. This article aims to provide a comprehensive overview of CNC turning, exploring its applications in diverse industries, the intricacies of the process, and the advantages it offers, establishing its vital role in the future of manufacturing.

What is CNC Turning?

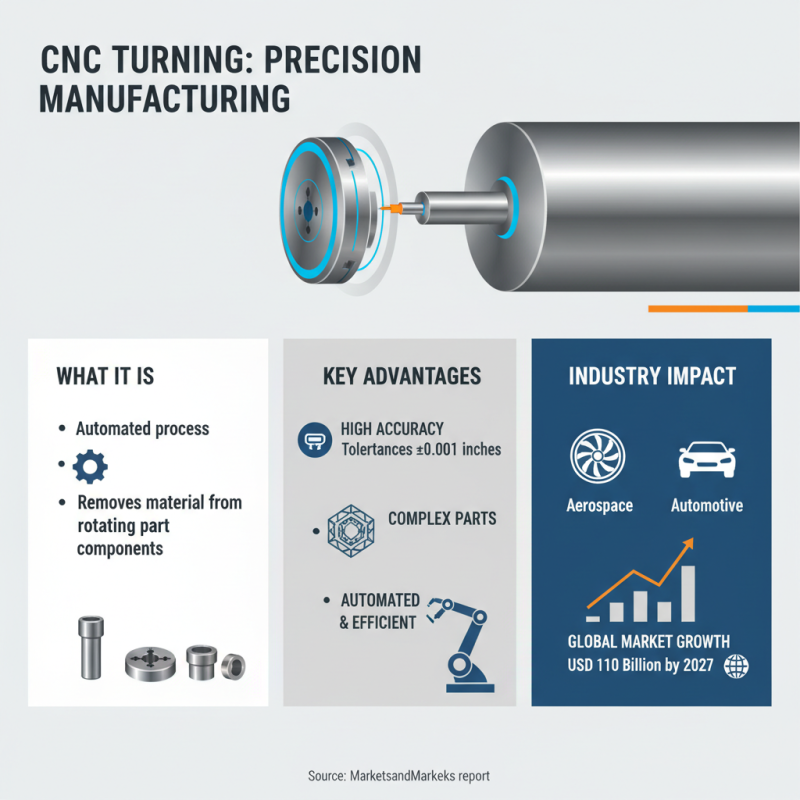

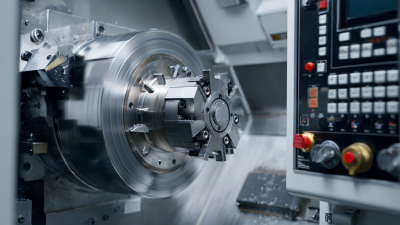

CNC turning, or Computer Numerical Control turning, is a manufacturing process that uses automated machinery to precisely remove material from a rotating workpiece. This technique is essential in producing cylindrical components with high accuracy, such as shafts, bushings, and fittings. With CNC turning, manufacturers can achieve tolerances as tight as ±0.001 inches, making it a critical process in industries like aerospace and automotive, where component precision is paramount. According to a report by MarketsandMarkets, the global CNC machine tools market is expected to reach USD 110 billion by 2027, driven in part by the increasing adoption of CNC turning for complex parts production.

Utilizing CNC turning not only enhances accuracy but also improves efficiency. Traditional turning methods often require manual intervention, which can introduce errors and slow down production. CNC turning, on the other hand, allows for continuous operation and the capability to monitor the process in real-time. This translates to reduced labor costs and fewer production errors, ultimately leading to enhanced profitability for manufacturers. It is worth noting that about 30% of time can be saved in production cycles when employing CNC turning techniques, according to a study by TechSci Research.

Tips: When considering CNC turning for production, ensure to evaluate the machine's capabilities and the complexity of the parts to be produced. Engaging in a thorough material selection process will also aid in optimizing the final product's performance. Additionally, regular maintenance of CNC machines is vital to prolong their operational lifespan and maintain precision.

Key Applications of CNC Turning in Various Industries

CNC turning is a versatile and efficient machining process widely applied across various industries due to its precision and ability to produce complex geometries. In manufacturing, for example, CNC turning is essential in the production of components such as shafts, fittings, and housings, which are fundamental in the automotive sector. These parts require high accuracy and consistency, and CNC turning ensures the replication of designs at scale while minimizing human error.

Beyond automotive, CNC turning finds key applications in the aerospace industry. Components like turbine housings and hydraulic systems necessitate meticulous engineering and dimensional accuracy to meet strict safety standards. The use of CNC turning technology optimizes the fabrication of these intricate parts, allowing for lightweight yet strong designs that are crucial in aircraft manufacturing. Similarly, in the medical industry, CNC turning plays a vital role in creating precision instruments and implants, where reliability and performance are paramount. The process allows for the customization of sizes and shapes suited to specific medical needs, showcasing the adaptability of CNC turning across different sectors.

The CNC Turning Process: Steps and Techniques Explained

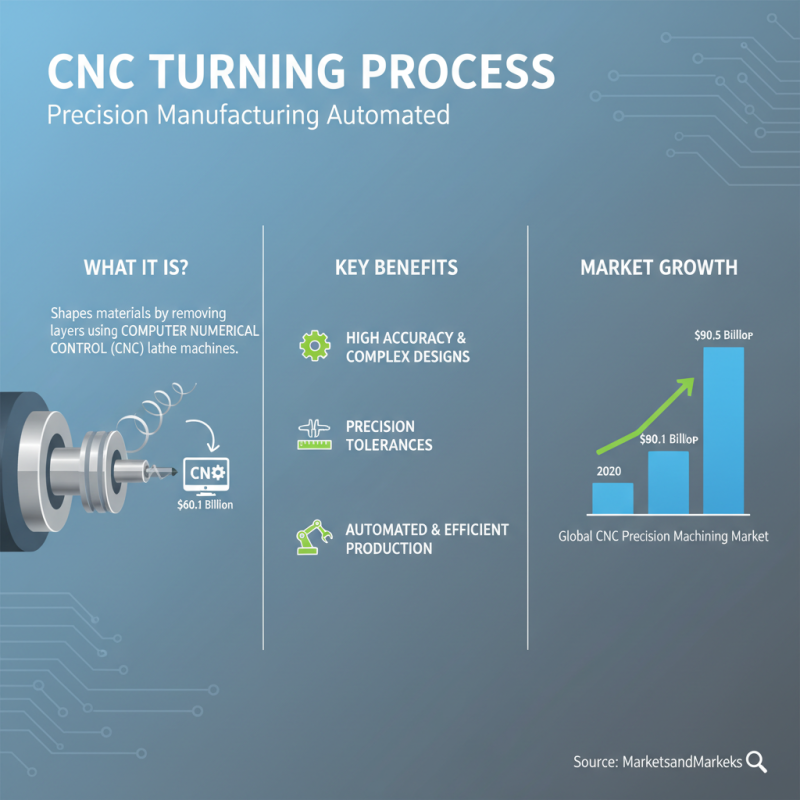

The CNC turning process is a sophisticated method used in manufacturing that involves the precise shaping of materials through the removal of excess layers. It utilizes computer numerical control technology to manage the operation of lathe machines, allowing for intricate designs and high levels of accuracy. According to a report by MarketsandMarkets, the CNC precision machining market is projected to reach $90.5 billion by 2026, highlighting the increasing reliance on automated processes in modern manufacturing.

The CNC turning process typically consists of several key steps, including design, programming, setup, and machining. Initially, a digital model is created using CAD software, which is then translated into G-code that directs the CNC machine. The setup involves securing the workpiece and configuring the tool to begin the turning process. Once initiated, the lathe machine rotates the material against a cutting tool, precisely shaping it into the desired form. Techniques such as live tooling and sub-spindle turning enhance the versatility of the process, allowing manufacturers to produce complex components efficiently. A report from Grand View Research indicates that the increasing demand for lightweight and durable materials in industries such as aerospace and automotive is driving advancements in CNC turning technologies.

Benefits of Using CNC Turning for Precision Machining

CNC turning is a highly efficient method in precision machining that offers numerous benefits for manufacturers and engineers alike. One of the key advantages of using CNC turning is its ability to achieve tight tolerances, often within +/- 0.001 inches or better, which is crucial in industries like aerospace and automotive where precision is paramount. According to a report by Grand View Research, the CNC machine market is projected to reach $117.20 billion by 2028, highlighting the growing reliance on CNC technology for producing complex components with high precision.

Additionally, CNC turning enhances production efficiency by automating the machining process. The integration of CNC technology enables manufacturers to produce parts faster and with fewer errors compared to traditional manual machining methods. For instance, a study by MarketsandMarkets indicates that the global CNC machine tools market is expected to grow at a CAGR of 6.9% from 2021 to 2026, driven largely by the increasing demand for automation in manufacturing processes. This efficiency not only reduces production time but also minimizes material waste, leading to cost savings and sustainability in manufacturing practices.

Overall, the adoption of CNC turning in precision machining not only elevates the quality and consistency of products but also aligns with industry trends towards more automated and efficient manufacturing solutions.

Future Trends in CNC Turning Technology and Innovations

The CNC turning industry is poised for significant advancements driven by ongoing technological innovations. One of the most notable trends is the integration of artificial intelligence and machine learning into CNC systems. These technologies allow for real-time monitoring and adjustment of machining processes, leading to enhanced precision and efficiency. By analyzing data from various sensors, AI can predict tool wear and suggest maintenance schedules, minimizing downtime and improving overall productivity.

Another emerging trend is the shift towards automation and digitalization. Smart manufacturing environments are becoming increasingly prevalent, where CNC turning machines are interconnected through the Internet of Things (IoT). This connectivity enables seamless data exchange and process optimization, allowing manufacturers to respond to market demands more swiftly. Additionally, advancements in additive manufacturing are complementing traditional CNC turning, enabling hybrid production methods that combine subtractive and additive processes for more complex geometries.

Sustainability is also becoming a focal point in CNC turning technology. Innovations aimed at reducing waste and energy consumption are gaining traction, with manufacturers exploring eco-friendly materials and energy-efficient machine designs. These efforts not only minimize the environmental footprint but also align with the growing consumer demand for sustainable practices in manufacturing. As CNC turning continues to evolve, these trends will shape the future landscape of the industry, driving it towards greater efficiency, connectivity, and sustainability.

Related Posts

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

Market Trends for Best CNC Lathe by 2025 and the Future of Advanced Machining Technologies

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers

-

Emerging Trends in CNC Vertical Machining Centers for 2025 A Comprehensive Guide