Real-World Applications of CNC Turning Centers in Diverse Industries

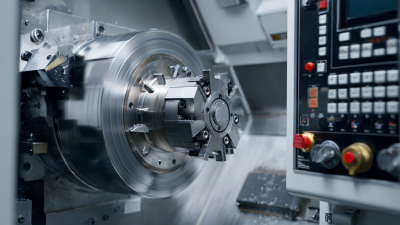

In the ever-evolving landscape of manufacturing, the CNC turning center has emerged as a vital tool across diverse industries, revolutionizing the way we approach precision machining. With its remarkable ability to produce intricate designs and high-quality components with unparalleled efficiency, the CNC turning center is not just a technological marvel; it is a game changer for businesses seeking to enhance productivity and reduce waste.

From the automotive sector, where precision is paramount for safety and performance, to the aerospace, medical, and electronics fields, these machines are redefining what is possible in terms of creativity and production capability. This blog will explore the myriad real-world applications of CNC turning centers, highlighting their significance in various industries and providing insights into how they help optimize operations, streamline workflows, and drive innovation.

Join us as we delve into the fascinating world of CNC turning centers and uncover their transformative impact on modern manufacturing.

Applications of CNC Turning Centers in Automotive Manufacturing

CNC turning centers have become indispensable in the automotive manufacturing industry, where precision and efficiency are paramount. These advanced machining tools enable the production of complex components with tight tolerances and intricate geometries, which are essential for the performance and safety of vehicles. From engine parts like crankshafts and camshafts to wheel hubs and transmission components, CNC turning centers ensure that each piece is crafted to meet stringent industry standards.

By automating the turning process, manufacturers can significantly reduce production times while enhancing the consistency and quality of their outputs. This capability allows for rapid prototyping and the efficient scaling of production, accommodating both high-volume runs and custom orders. Additionally, the integration of CNC turning centers with CAD/CAM software streamlines the design-to-manufacturing process, empowering engineers and designers to innovate without the constraints of traditional machining methods. This alignment of technology with automotive needs not only enhances productivity but also supports the industry's push towards more sustainable manufacturing practices.

Precision Engineering: The Role of CNC Turning in Aerospace Components

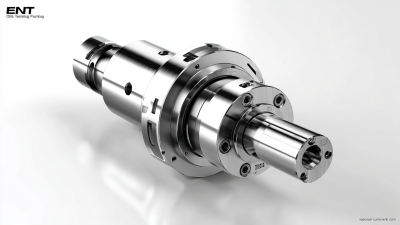

CNC turning centers have revolutionized the production of aerospace components by delivering unparalleled precision and efficiency. In the aerospace sector, where tolerances can be exceedingly tight and reliability is paramount, CNC turning plays a crucial role in manufacturing essential parts such as engine components, landing gear, and other critical assemblies. The advanced capabilities of CNC machining allow for complex geometries and intricate designs to be realized, ensuring that aerospace manufacturers can meet stringent safety and performance standards.

As the demand for high-quality aerospace components continues to surge, companies like Precision Aerospace Holdings are leveraging CNC technology to enhance their production capabilities. The integration of advanced CNC turning centers facilitates a significant reduction in lead times while maintaining superior quality assurance. This positioning not only strengthens their competitive edge in the rapidly evolving aerospace market but also underscores the importance of precision engineering in supporting global defense and aerospace initiatives. The ongoing advancements in CNC technology promise to further enhance manufacturing processes, driving innovation and reliability in the aerospace industry.

Innovative Solutions: CNC Turning in Medical Device Production

CNC turning centers have revolutionized the production of medical devices, offering precision and efficiency that traditional manufacturing methods cannot match. These advanced machines allow for the creation of complex and intricate parts, such as surgical instruments and implants, ensuring they meet stringent quality standards. With the medical industry constantly evolving, CNC turning provides innovative solutions to design challenges, enabling manufacturers to develop products that are not only functional but also tailored to specific patient needs.

When implementing CNC turning in medical device production, it is essential to consider the choice of materials. Opt for biocompatible materials that ensure safety and effectiveness for patients. Additionally, conducting thorough testing and validating processes will help ensure that the devices meet regulatory requirements.

Another key tip is to invest in operator training. Skilled operators can maximize the potential of CNC turning centers, leading to improved productivity and reduced errors. Regular maintenance and updates to the machinery can enhance performance and extend the longevity of the equipment, ultimately benefiting the quality of the final product.

Enhancing Efficiency: CNC Turning Centers in Electronics Manufacturing

CNC turning centers have become indispensable in the electronics manufacturing sector, significantly enhancing efficiency and precision. As industries increasingly adopt advanced digital manufacturing technologies, CNC machines are at the forefront of this transformation. The growing demand for high-quality electronic components necessitates precise machining capabilities, and CNC turning centers deliver on this demand, ensuring optimal performance and reduced production times.

The market for CNC machines is projected to reach USD 170.4 billion by 2033, showcasing a substantial growth trajectory fueled by the increasing reliance on automation in manufacturing processes. In particular, the integration of AI-driven technologies is redefining the landscape of CNC machining. Manufacturers can leverage these innovations not only to improve operational efficiency but also to adapt swiftly to evolving market needs, further solidifying the role of CNC turning centers as vital instruments in electronics production. Such advancements underscore the importance of CNC technology in not just meeting current demands but also anticipating future trends in the industry.

Real-World Applications of CNC Turning Centers in Electronics Manufacturing

This chart illustrates the efficiency gains in various electronic components manufacturing processes through the implementation of CNC turning centers. The data highlights the percentage increase in production efficiency across different categories.

Custom Solutions: Tailored Applications of CNC Turning in Small Businesses

CNC turning centers have revolutionized manufacturing processes across various small businesses, offering tailored applications that meet specific production needs. According to a report by Technavio, the global CNC machine market is projected to grow by over $7.0 billion from 2021 to 2025, indicating a significant trend towards automation and customization. Small businesses, particularly in industries such as automotive and aerospace, utilize CNC turning to produce intricate parts with precision and efficiency. This technology allows for short production runs, which is essential for small enterprises that cater to niche markets.

Moreover, the adaptability of CNC turning centers enables small businesses to innovate and offer customized solutions to their clientele. For example, a manufacturer producing bespoke components can quickly recalibrate their CNC machines to accommodate varying designs without extensive downtime, significantly enhancing productivity. A study by the American Society of Mechanical Engineers highlighted that businesses implementing CNC machining saw productivity improvements of up to 40%, emphasizing the advantages of integrating such technology. By leveraging CNC turning, small businesses can remain competitive and responsive to market demands while enhancing the quality and consistency of their outputs.

Related Posts

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers

-

Top Strategies for Choosing the Best CNC Turning Machine for Your Business

-

Essential Checklist for Sourcing Quality CNC Machine Parts in Global Markets