Top 5 Essential CNC Lathe Parts for Precision Machining Success

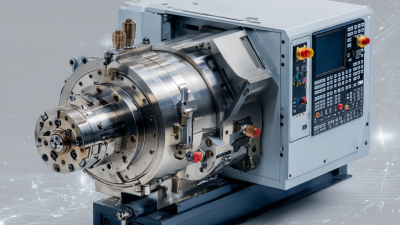

In the realm of precision machining, understanding the critical components that contribute to the efficiency and accuracy of CNC lathes is paramount. As industry expert John Smith, a leading authority in CNC technology, aptly stated, "The quality and compatibility of CNC lathe parts are integral to achieving optimal machining results." This highlights the need for machinists and manufacturers to prioritize the selection of CNC lathe components to ensure operational excellence.

CNC lathe parts not only influence the machine's performance but also play a significant role in the longevity and reliability of machining processes. From spindles to tool holders, each component must be meticulously assessed to meet the specific demands of various applications. As we explore the top five essential CNC lathe parts for precision machining success, it becomes evident that investing in high-quality components is less of an option and more of a necessity for those aiming to stay competitive in an evolving industry.

Key Features of CNC Lathes That Enhance Machining Precision

When it comes to achieving precise machining outcomes, the CNC lathe stands out as a critical component in manufacturing. Within the realm of CNC lathes, some key features greatly enhance machining precision. Features such as high-speed spindle systems, advanced feedback mechanisms, and robust control software enable manufacturers to achieve tighter tolerances and superior surface finishes. A market research study indicates that the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This growth is largely fueled by the increasing demand for precision manufacturing processes.

Tips for maximizing precision in CNC machining include regularly calibrating machinery and optimizing tool paths to reduce cycle time without compromising accuracy. Additionally, utilizing high-quality materials and precision tooling can substantially enhance the final product quality. As industries continue to evolve towards automation, understanding the essential components of CNC lathes will be crucial for manufacturers aiming for efficiency and precision.

Moreover, as the demand for precision machined parts rises, it is essential to be aware of market trends. With the precision turned product manufacturing market expected to hit USD 196.11 billion by 2034, investing in advanced CNC technology can provide a competitive edge. Adopting five-axis machining centers in particular allows for the creation of complex geometries, which are increasingly sought after in modern applications.

Top 5 Essential CNC Lathe Parts for Precision Machining Success

| CNC Lathe Part | Key Features | Impact on Precision |

|---|---|---|

| Spindle | High-speed rotation, low vibration | Ensures smooth cutting and reduces runout |

| Tool Holder | Quick-change design, rigidity | Minimizes setup time and maintains tool stability |

| Chuck | Hydraulic or manual clamping, precision jaws | Enhances workpiece gripping and alignment |

| Control System | CNC interface, programmable features | Allows for complex geometries and repeatability |

| Bed | Rigid construction, precision rails | Provides stability and minimizes deflection during machining |

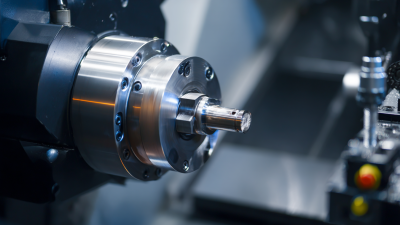

Essential Components for Maintaining CNC Lathe Accuracy

The accuracy of a CNC lathe is pivotal for achieving precise machining outcomes. Key components such as the spindle, tailstock, and tool holders play a significant role in maintaining this accuracy. The spindle, responsible for rotating the workpiece, must be durable and precisely manufactured to ensure that it can handle high speeds without compromising stability. The tailstock supports the opposite end of the workpiece, and any wear or misalignment can lead to significant deviations during machining, making its maintenance essential.

Tool holders also deserve attention, as they secure the cutting tools in place and must provide consistent performance to avoid tool movement during operations. Additionally, the bed of the lathe, where these components are mounted, needs to be rigid and accurately aligned. Any distortion in the bed can affect the entire machining process. As the global CNC lathe market continues to grow, projected to reach $57.54 billion by 2032 with a CAGR of 5.6% from 2018, the importance of these essential components in maintaining accuracy becomes increasingly critical for manufacturers striving for machining success.

Innovative Technologies in CNC Lathe Parts for Improved Performance

The integration of innovative technologies in CNC lathe parts is revolutionizing precision machining, driving productivity across various industries. Digital manufacturing technologies, including advanced automation and smart sensors, enhance the efficiency of CNC lathes, allowing for higher accuracy and faster production cycles. These developments enable manufacturers to respond quickly to market demands while maintaining stringent quality control.

Furthermore, companies are shifting their focus from merely meeting domestic needs to competing on a global scale. This transition underscores the rise of intelligent manufacturing practices, which not only streamline operations but also enhance product capabilities. The unveiling of new high-end machine tools emphasizes this trend, showcasing a commitment to leadership in the market and a dedication to continuous improvement in performance. As the industry evolves, the adoption of cutting-edge technologies will play a crucial role in defining success within the field of precision machining.

Tips for Selecting Quality CNC Lathe Parts for Optimal Results

When selecting CNC lathe parts for precision machining, it is essential to prioritize quality to ensure optimal results. The choice of materials and the precision of manufacturing directly impact the performance of the lathe. High-quality components not only enhance accuracy and efficiency but also extend the lifespan of the machine. Seek parts made from durable materials with tight tolerances to minimize wear and prevent costly downtime associated with failures.

Additionally, understanding the specific requirements of your machining projects can guide you in making informed selections. Consider factors such as the type of machining tasks, desired finish quality, and machining speed. Research various manufacturers and compare features and prices, ensuring that you choose reputable sources that offer reliable support. Investing time in evaluating CNC lathe parts not only leads to better machining outcomes but also contributes to a streamlined production process, ultimately driving success in precision machining endeavors.

Top 5 Essential CNC Lathe Parts for Precision Machining Success

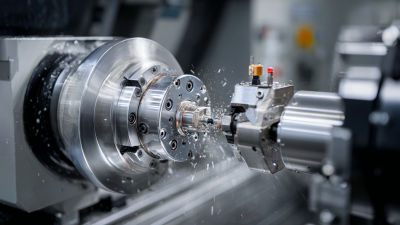

Maintenance Practices to Ensure Longevity of CNC Lathe Components

Maintaining the longevity of CNC lathe components is crucial for ensuring consistent precision in machining operations. Regular inspection of critical parts such as the spindle, tool holder, and drive belt is essential. Operators should implement a routine check that includes looking for wear and tear, as well as ensuring that all components are properly lubricated. Lubrication not only reduces friction but also prevents overheating, which can severely damage sensitive parts and lead to costly repairs.

Additionally, it’s vital to maintain the cleanliness of the lathe environment. Dust and debris can accumulate in moving parts, causing misalignment and reducing overall efficiency. Scheduled cleaning intervals should be established to remove any buildup. Moreover, regular calibration of the machine aids in maintaining precision, as even slight misalignments can affect machining accuracy. Adopting these maintenance practices will not only extend the life of CNC lathe components but also ensure sustained success in precision machining.

Related Posts

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

7 Reasons Why the Best Small CNC Lathe Can Transform Your Manufacturing Efficiency

-

Discover the Excellence of Quality China Made CNC Machine Tools for Global Markets

-

How to Optimize Production Efficiency with CNC Turning Centers

-

Unlocking Precision: The Impact of CNC Machine Tools on Manufacturing Efficiency in 2023

-

What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency