Top Features to Consider When Buying a CNC Milling Machine for Your Workshop

In the rapidly evolving landscape of manufacturing, the CNC milling machine stands as a cornerstone for precision engineering in workshops across various industries. According to a recent IBISWorld report, the global CNC machining services market is expected to grow at an annual rate of 4.1%, reaching a value of approximately $70 billion by 2026. This growth underscores the increasing reliance on CNC technologies, where the efficiency, accuracy, and flexibility of CNC milling machines are paramount.

Industry expert Dr. Jane Roberts, a leading figure in CNC technology research, emphasizes the importance of selecting the right machine by stating, "Investing in a quality CNC milling machine is not just about immediate cost; it's about the long-term impact on productivity and innovation." As workshop owners face an array of choices with diverse functionalities, understanding the crucial features of CNC milling machines becomes essential for making informed purchasing decisions.

In this guide, we will delve into the top features to consider when acquiring a CNC milling machine for your workshop, ensuring that you are equipped with the knowledge to enhance your production capabilities and drive your business forward. From precision specifications to software compatibility, every aspect plays a vital role in the machine's overall performance and suitability for your specific needs.

Key Specifications to Assess for CNC Milling Machines

When considering the purchase of a CNC milling machine for your workshop, assessing key specifications is essential to ensure you choose the right fit for your operations. One of the most critical specifications to evaluate is the machine's axis configuration. Most CNC milling machines come with at least three axes, which allow for complex shapes and designs. However, advanced models with five or more axes provide greater flexibility and precision, enabling intricate machining processes while reducing the need for multiple setups. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow from $62.68 billion in 2020 to $100.9 billion by 2025, highlighting the increasing demand for high-precision equipment across various industries.

Another vital aspect to consider is the spindle speed and power. The spindle speed, usually measured in RPM (revolutions per minute), determines how quickly the machine can operate, which directly impacts productivity. A higher spindle speed allows for faster material removal rates, especially when working with softer materials. The spindle power, measured in kilowatts or horsepower, indicates the machine's ability to handle tougher materials. Variability in these specifications can significantly affect overall efficiency; for instance, a study from the International Journal of Scientific & Engineering Research indicates that optimizing spindle speed can result in a 20-30% increase in machining efficiency, making it a critical parameter in your purchasing decision.

Types of CNC Milling Machines and Their Applications

When considering a CNC milling machine for your workshop, it's essential to understand the different types available and their specific applications. CNC milling machines can be broadly categorized into vertical and horizontal milling machines. Vertical machines feature a spindle that points downwards, making them ideal for precision work on flat surfaces, intricate designs, and drilling operations. They are commonly used in industries such as aerospace, automotive, and metal fabrication, where detailed precision is paramount.

On the other hand, horizontal CNC milling machines have a spindle that is oriented horizontally, which allows for greater stability and the ability to handle larger workpieces. These are particularly advantageous for heavy-duty operations and are often used for manufacturing complex parts that require multiple processes to be performed in a single setup. Products from sectors such as energy, defense, and large-scale manufacturing benefit from the capabilities of horizontal machining centers due to their efficiency and robustness. Understanding these distinctions will help you choose the right CNC milling machine that aligns with your workshop's specific production needs.

Top Features to Consider When Buying a CNC Milling Machine

Understanding CNC Machine Tolerance and Precision Levels

When selecting a CNC milling machine for your workshop, understanding machine tolerance and precision is crucial. Tolerance refers to the allowable deviation from a specified dimension, which can significantly impact the quality of the finished product. Depending on the projects you take on, knowing the required tolerance levels can help you choose the right machine. For instance, intricate designs or components that fit together precisely demand a machine capable of achieving tight tolerances. Therefore, evaluating the machine's capability to maintain these specifications reliably is essential for producing high-quality results.

Precision levels are another critical aspect to consider, as they determine how accurately the machine can reproduce a design. A CNC milling machine with high precision will ensure that each piece produced matches the intended dimensions, reducing the need for extensive post-processing. When assessing precision, look for specifications that indicate repeatability and accuracy, as these metrics provide insight into the machine's performance under various conditions. By prioritizing tolerance and precision, you can make a well-informed decision, ensuring your CNC milling machine meets the rigorous demands of your workshop applications.

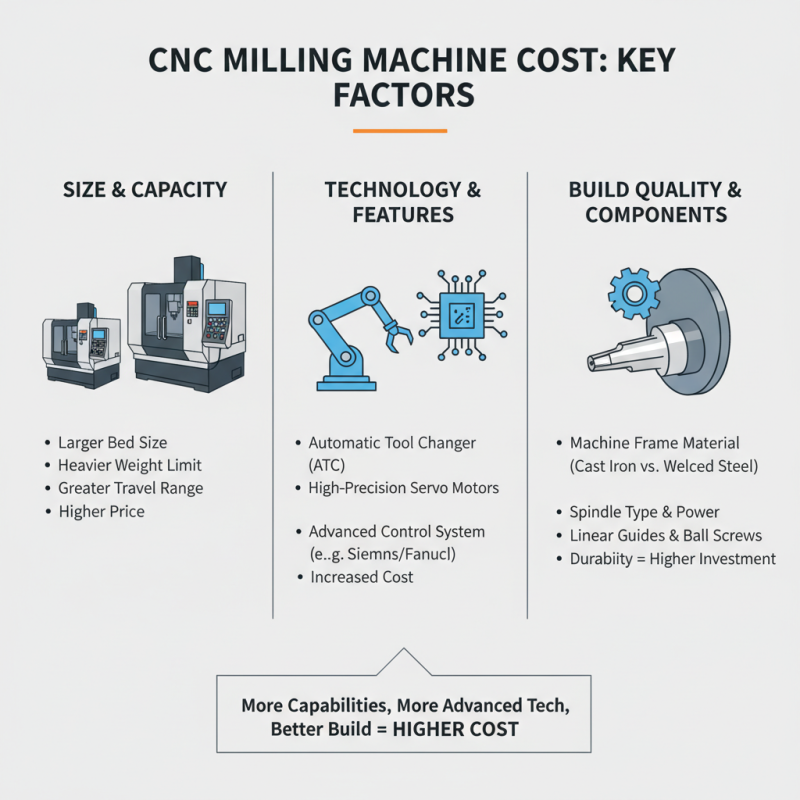

Factors Influencing the Cost of CNC Milling Machines

When considering the purchase of a CNC milling machine for your workshop, it's crucial to understand the various factors that influence their cost. The machine's size and capacity are primary determinants; larger machines with greater capabilities tend to command higher prices. Additionally, the technology used in the machine plays a significant role. Machines equipped with advanced features like automatic tool changing, high precision servo motors, and enhanced control systems will typically be more expensive than their basic counterparts.

Another key factor is the level of durability and build quality. Machines constructed from high-grade materials and designed for rigorous usage generally come with a higher upfront cost. However, investing in a sturdy machine can result in better performance and lower maintenance costs over time.

**Tips:** When evaluating options, focus on the total cost of ownership rather than just the initial purchase price. Consider long-term operational costs, potential downtime, and maintenance fees. Moreover, evaluate the availability of parts and service; investing in equipment with strong support can save you money in the long run. Lastly, do not underestimate the importance of user training—it can have a significant impact on the efficiency and productivity of your new CNC milling machine.

Essential Software Compatibility for CNC Milling Operations

When selecting a CNC milling machine for your workshop, ensuring compatibility with essential software is crucial. The right software can greatly enhance the machine's efficiency and the quality of the finished products. Look for CNC milling machines that support popular CAM (Computer-Aided Manufacturing) software packages, as these are often used to create intricate designs and automate machining processes. Additionally, consider whether the machine can handle various file formats, which may be necessary for integrating with different design software used in your business.

Moreover, the usability of the CNC machine's software interface can significantly impact your workflow. An intuitive user interface can simplify the programming process, allowing operators, regardless of their experience level, to quickly navigate through complex tasks. Compatibility with CAD (Computer-Aided Design) software is also essential since it enables seamless transition from design to production. A machine capable of integrating design and manufacturing software not only streamlines operations but also minimizes the risk of errors during the machining process. Always evaluate the software requirements and ensure it aligns with your current and future operational needs.

Related Posts

-

How to Optimize CNC Mill Performance for Maximum Efficiency and Precision

-

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering

-

Unlocking Precision: The Impact of CNC Machine Tools on Manufacturing Efficiency in 2023

-

Mastering CNC Milling and Turning: A Comprehensive Tutorial for Precision Manufacturing

-

Top 10 CNC Milling Parts You Need for Precision Engineering Success

-

Revolutionizing Precision: How CNC Machine Tools are Shaping the Future of Manufacturing Technology