Exploring the Future of CNC Machine Tools: Innovations Driving the Next Manufacturing Revolution

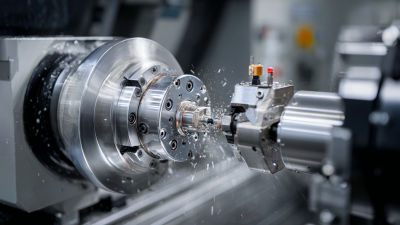

As we stand on the brink of a new era in manufacturing, the evolution of CNC machine tools is set to play a pivotal role in shaping the industry's future. These advanced machines, which have already transformed the landscape of precision engineering, are now integrating cutting-edge technologies such as artificial intelligence, IoT, and automation to enhance their capabilities further. This article delves into the innovations driving this next manufacturing revolution, examining how CNC machine tools are not only improving efficiency and accuracy but also enabling greater flexibility and customization in production processes. As we explore these advancements, we will uncover tips and insights for manufacturers seeking to leverage the full potential of CNC machine tools and stay ahead in a rapidly changing market. With the right approach and understanding of these innovations, businesses can navigate the complexities of modern manufacturing and unlock new opportunities for growth and success.

Innovative Technologies Shaping CNC Machine Tools for Tomorrow

The future of CNC machine tools is being defined by a series of innovative technologies that promise to revolutionize the manufacturing industry. One of the most significant advancements is the integration of artificial intelligence and machine learning algorithms. These technologies enable CNC machines to analyze performance data in real-time, leading to enhanced decision-making processes. By predicting when maintenance is needed and optimizing production schedules, these smart systems can significantly reduce downtime and improve efficiency.

Additionally, the advent of additive manufacturing techniques is poised to reshape the landscape of CNC machining. By combining subtractive and additive processes, manufacturers can enhance design flexibility and material usage, resulting in more sustainable production methods. Furthermore, advancements in materials science, such as the development of high-strength composites and lightweight alloys, are expanding the capabilities of CNC machines, allowing for the production of more complex geometries with improved strength-to-weight ratios. As these innovative technologies continue to evolve, they will play a critical role in shaping the CNC machine tools of tomorrow, driving forward the next manufacturing revolution.

The Role of Automation and AI in Enhancing CNC Machining Efficiency

The landscape of CNC (Computer Numerical Control) machining is rapidly evolving, with automation and artificial intelligence (AI) playing pivotal roles in enhancing efficiency and precision. The integration of AI into CNC machines enables them to learn from past operations, predict maintenance needs, and adapt to varying manufacturing conditions. This not only optimizes performance but also reduces downtime, leading to significant cost savings and improved productivity.

Tips: To get the most out of your CNC tools, consider investing in AI-driven software that can analyze your machining processes. This software can offer insights on optimizing feeds and speeds, thus extending tool life and improving surface finishes.

Furthermore, automation technologies, such as robotic arms and conveyor systems, complement CNC machines by streamlining production processes. These systems can handle material loading and unloading, which minimizes human error and speeds up operations. As manufacturers increasingly embrace these technologies, they find themselves capable of short-run productions with a level of automation that was previously reserved for high-volume manufacturing.

Tips: Regularly evaluate your automation setup to identify areas for improvement. Simple adjustments, such as better alignment or upgrading to more sophisticated robotics, can enhance the overall efficiency of your production line.

Sustainability Trends in CNC Machine Tool Development

As CNC machine tool development moves toward the future, sustainability trends are becoming a pivotal focus in the industry. According to a market research study by Custom Market Insights, the global machine tools market, valued at approximately $228.3 billion, is projected to experience significant growth from 2025 to 2034. This expansion is driven by the increasing demand for high-precision and automated equipment, showcasing the industry's shift towards sustainable practices and advanced CNC technologies.

In particular, the Asia Pacific machine tools market is anticipated to play a crucial role in this growth, with projections highlighting a resilient market fueled by innovation and sustainability efforts. Reports predict that by 2033, the woodworking CNC tools market could grow to USD 13.4 billion, reflecting a compound annual growth rate (CAGR) of 5.0%. This surge is largely attributed to the rising demand for precision engineering, as well as a growing emphasis on eco-friendly manufacturing practices. Events like the Taiwan International Machine Tool Show have further emphasized dual themes of Digital Transformation and Green Transformation, indicating a clear industry alignment towards sustainable development goals.

Exploring the Future of CNC Machine Tools: Sustainability Trends

Future Materials and Their Impact on CNC Manufacturing Processes

Future materials are poised to revolutionize CNC manufacturing processes, introducing unprecedented possibilities in design and functionality. Advances in composite materials, such as carbon fiber and advanced thermoplastics, offer lightweight yet durable alternatives to traditional metals. These materials not only enhance the performance of finished products but also reduce machining time and energy consumption during production. As CNC machines become more adept at handling these specialized materials, manufacturers can push the boundaries of creativity and productivity.

Additionally, the development of smart materials—substances that respond dynamically to environmental stimuli—can significantly enhance CNC machining capabilities. For instance, materials that change shape or properties in response to temperature or stress can lead to innovative solutions in industries such as aerospace and automotive. Integrating these smart materials into CNC manufacturing processes requires a rethinking of machining strategies, tools, and technologies. As manufacturers begin to harness the potential of future materials, the CNC industry stands on the brink of a transformative era that promises to redefine efficiency, sustainability, and design.

The Importance of Software Integration in Next-Gen CNC Systems

The advancement of CNC (Computer Numerical Control) machine tools is heavily influenced by the integration of sophisticated software systems. According to a report by MarketsandMarkets, the global CNC software market is projected to reach USD 6.3 billion by 2025, growing at a CAGR of 6.4% from 2020 to 2025. This growth underscores the critical role that software integration plays in enhancing the functionality and efficiency of CNC systems. Modern CNC machines equipped with advanced software can optimize machining processes, improve accuracy, and reduce downtime, directly impacting overall productivity in manufacturing.

As industries move towards Industry 4.0, the focus on smart manufacturing solutions becomes paramount. Software integration enables real-time monitoring and data analytics, allowing manufacturers to make informed decisions quickly. A report from Deloitte shows that companies leveraging advanced analytics in their CNC operations can boost productivity by up to 15%. This ability to adapt and optimize production processes in real-time is vital for maintaining a competitive edge in the fast-evolving manufacturing landscape. The seamless integration of software with CNC systems not only enhances operational efficiency but also paves the way for innovative manufacturing practices, driving the next revolution in the industry.

Related Posts

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

7 Amazing CNC Machine Innovations Changing the Industry Forever

-

How to Optimize Production Efficiency with CNC Turning Centers

-

Challenges Associated with Choosing the Best CNC Milling Machine for Your Needs

-

How to Choose the Best Multi Axis CNC Machine for Your Manufacturing Needs

-

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering