Unlocking Precision: The Impact of CNC Machine Tools on Manufacturing Efficiency in 2023

In 2023, the manufacturing landscape is increasingly defined by the integration of technology, with CNC machine tools standing at the forefront of this transformation. According to a report by MarketsandMarkets, the global CNC machine tools market is projected to reach $100 billion by 2026, driven by the demand for precision and efficiency across various industries. The ability of CNC machine tools to enhance manufacturing processes is evidenced by a significant reduction in production times and increased accuracy levels, impacting everything from aerospace to automotive sectors. As manufacturers face the dual challenges of rising labor costs and the need for high-quality production, embracing CNC technology has become essential. Furthermore, a survey by KPMG highlights that 80% of manufacturers believe that automation through tools like CNC machines will greatly contribute to their operational efficiency and competitiveness in the coming years. This evolution not only underscores the importance of CNC machine tools but also sets the stage for a more productive and innovative manufacturing future.

The Evolution of CNC Machine Tools in Modern Manufacturing

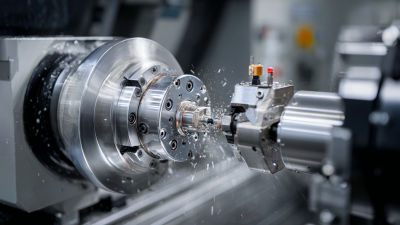

The evolution of CNC (Computer Numerical Control) machine tools has significantly transformed modern manufacturing, driving efficiency and precision to new heights. According to a report by MarketsandMarkets, the CNC machine tool market is projected to reach USD 100 billion by 2026, growing at a CAGR of 6.7%. This growth is largely driven by the demand for automation in production processes, allowing manufacturers to streamline operations and reduce human error. The advancements in CNC technology have also introduced capabilities such as multi-axis machining and increased tooling options, enabling factories to produce complex components with unmatched precision.

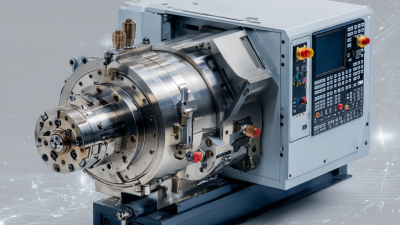

Moreover, the integration of Industry 4.0 technologies with CNC machinery enhances operational efficiency. A study by the Massachusetts Institute of Technology found that manufacturers utilizing smart CNC machines can increase production uptime by up to 20% through predictive maintenance and real-time monitoring. This data reflects the increasing necessity for manufacturers to adopt advanced CNC technologies, not only to keep pace with industry standards but also to achieve greater flexibility and responsiveness in their production lines. As CNC machine tools continue to evolve, they are set to play a pivotal role in redefining manufacturing efficiency in the years to come.

Unlocking Precision: The Impact of CNC Machine Tools on Manufacturing Efficiency in 2023

| Aspect | 2021 | 2022 | 2023 |

|---|---|---|---|

| Market Size (Billion USD) | 5.6 | 6.2 | 7.0 |

| Growth Rate (%) | 4.5 | 10.7 | 12.9 |

| CNC Production Efficiency (%) | 75 | 78 | 82 |

| Adoption Rate (%) | 40 | 52 | 65 |

| Types of CNC Machines in Use (%) | 35 (Mills) | 30 (Lathes) | 20 (Plasma) |

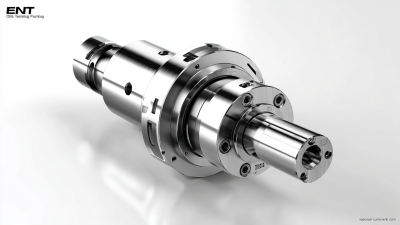

Key Technologies Driving CNC Machine Tool Precision

The demand for precision in manufacturing is driving significant advancements in CNC (Computer Numerical Control) machine tools, with the global market anticipated to grow from $13.263 billion in 2025 to $22.946 billion by 2032. This steady expansion, projected at a compound annual growth rate (CAGR) of 8.1%, underscores the increasing emphasis on high accuracy and efficiency in production processes. In particular, the grinding machine sector, which was valued at $4.72 billion in 2018, is expected to reach $9.01 billion by 2032, reflecting a CAGR of 4.4%. The Asia-Pacific region dominated the grinding machine market in 2018, holding a considerable share of 55.51%, illustrating its key role in global manufacturing dynamics.

Emerging technologies, particularly within the framework of the Industrial Internet of Things (IIoT), are transforming the capabilities of CNC machine tools. By enabling seamless communication and connectivity among frontline production devices, companies can vastly improve operational efficiency and data transmission accuracy. This interconnectedness paves the way for advanced functionalities and smarter automation solutions, allowing manufacturers to shift from traditional operational practices to innovative digital manufacturing technologies. The ongoing integration of precision CNC tools is crucial for meeting the growing demands for higher productivity across diverse industries.

Enhancing Productivity: CNC Techniques for Streamlined Operations

CNC (Computer Numerical Control) machine tools have revolutionized manufacturing processes, significantly enhancing productivity through precision and automation. According to a recent report from the International Federation of Robotics, the global market for CNC machines is expected to grow by over 8% annually, underscoring their critical role in modern manufacturing. By reducing human error and increasing consistency in production, CNC techniques enable manufacturers to streamline their operations, ultimately contributing to faster turnaround times and superior product quality.

The adoption of advanced CNC techniques, such as multi-axis machining and adaptive control systems, further optimizes manufacturing workflows. A study by McKinsey & Company indicates that companies utilizing CNC technology can increase their operational efficiency by up to 30%. This efficiency is achieved by minimizing setup times, improving machining speeds, and enabling complex geometries to be produced with ease. As businesses strive to remain competitive in a rapidly evolving market, leveraging CNC capabilities is essential for cultivating a more agile and responsive manufacturing environment.

Measuring Efficiency: Quantifiable Benefits of CNC Integration

The integration of CNC (Computer Numerical Control) machine tools into manufacturing processes in 2023 has significantly transformed the landscape of efficiency measurement. By automating complex machining tasks, CNC technology enables manufacturers to achieve precision that manual methods simply cannot replicate. This precision not only reduces the margin of error but also minimizes material waste, leading to cost savings and enhanced productivity. Metrics such as cycle time, set-up time, and defect rates are now quantifiable, providing manufacturers with clear data to analyze performance improvements.

Furthermore, CNC machine tools facilitate streamlined production workflows. With the ability to program multiple operations within a single setup, the time traditionally spent on machine changeovers is drastically reduced. This has resulted in increased output rates and faster turnarounds for orders. In addition, real-time monitoring capabilities allow for immediate adjustments during production, further enhancing operational efficiency. The quantifiable benefits of CNC integration, therefore, reflect not just in improved output but also in strategic resource optimization, fostering a competitive edge in the manufacturing industry.

Future Trends: The Role of CNC in Sustainable Manufacturing Practices

In 2023, the role of CNC (Computer Numerical Control) machine tools has evolved significantly, particularly in the context of sustainable manufacturing practices. As industries strive to minimize their environmental footprint, CNC technology offers innovative solutions that enhance resource efficiency. These advanced machines enable precise material removal and reduce waste, allowing manufacturers to optimize their resource usage and create fewer byproducts. This precision directly correlates with the reduction of excess material consumption, leading to not only cost savings but also a greener manufacturing process.

Furthermore, CNC machine tools facilitate the use of sustainable materials and processes. With their ability to work with a wide range of eco-friendly materials, manufacturers can leverage CNC technology to create products that align with sustainability goals. Additionally, the integration of smart technologies and data analytics into CNC systems supports real-time monitoring and optimization of production processes. This synergy aids in minimizing energy consumption and improving overall efficiency, making CNC an indispensable component of sustainable manufacturing strategies in 2023 and beyond. The trend towards automation and intelligent manufacturing is set to continue, further cementing the role of CNC machine tools in a more sustainable future.

Related Posts

-

Discover the Excellence of Quality China Made CNC Machine Tools for Global Markets

-

How to Optimize Production Efficiency with CNC Turning Centers

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Emerging Trends in CNC Vertical Machining Centers for 2025 A Comprehensive Guide