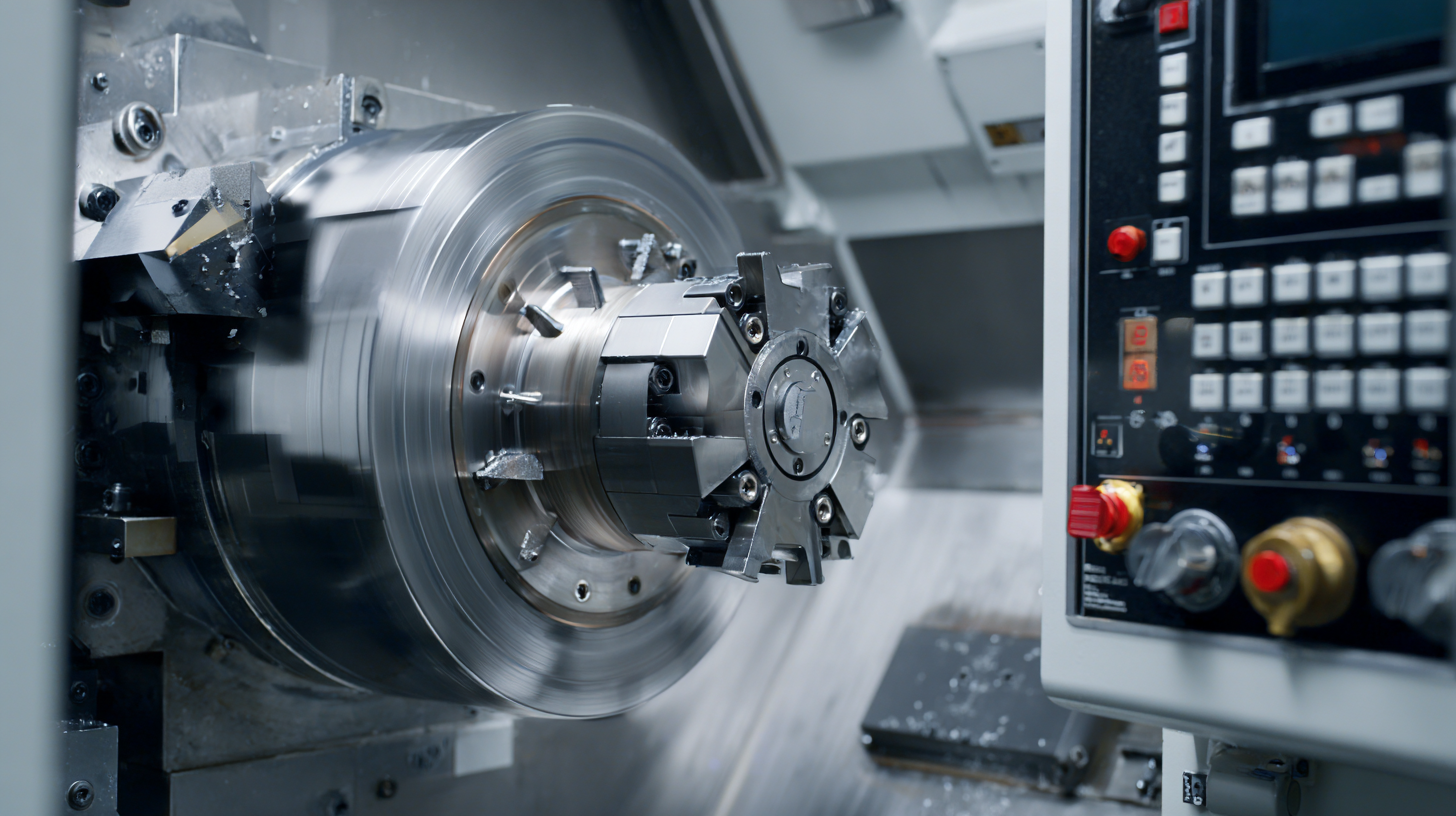

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

In today's rapidly evolving manufacturing landscape, the significance of import and export certifications for CNC turning machines cannot be overstated. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2026, driven by the increasing adoption of automation and precision engineering. In this context, understanding the various certifications that govern the import and export of CNC turning machines is crucial for manufacturers aiming to meet international standards and remain competitive. Certified machines not only assure quality and compliance but also enhance marketability in overseas markets, where regulatory frameworks can vary significantly. Thus, diving into the benefits of these certifications can provide manufacturers with valuable insights into optimizing their operations and expanding their global footprint.

Key Certifications Required for Importing CNC Turning Machines

When considering the import of CNC turning machines, understanding the necessary certifications is crucial for compliance and operation. Key certifications such as CE marking, ISO certification, and local safety standards play a vital role in ensuring that imported machinery meets the required safety and quality benchmarks. These certifications not only facilitate smoother customs processes but also assure buyers about the reliability and performance of the machines they are investing in.

In the current landscape, where the industry faces technological restrictions, particularly from major manufacturing hubs, navigating the certification process becomes even more imperative. As companies seek to innovate and overcome these limitations, adherence to rigorous certification standards can serve as a gateway for new entrants to establish credibility and gain market access. By prioritizing essential certifications, manufacturers can position themselves competitively, even in a challenging environment marked by ongoing debates on technology constraints.

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market - Key Certifications Required for Importing CNC Turning Machines

| Certification Name | Issuing Authority | Purpose | Region |

|---|---|---|---|

| CE Marking | European Union | Indicates compliance with health and safety standards | EU Member States |

| ISO 9001 | International Organization for Standardization | Quality management systems certification | Global |

| UL Certification | Underwriters Laboratories | Safety certification for electrical devices | USA |

| RoHS Compliance | European Union | Restriction of hazardous substances in electrical equipment | EU Member States |

| FDA Approval | Food and Drug Administration | Approval of machines used in food and medical applications | USA |

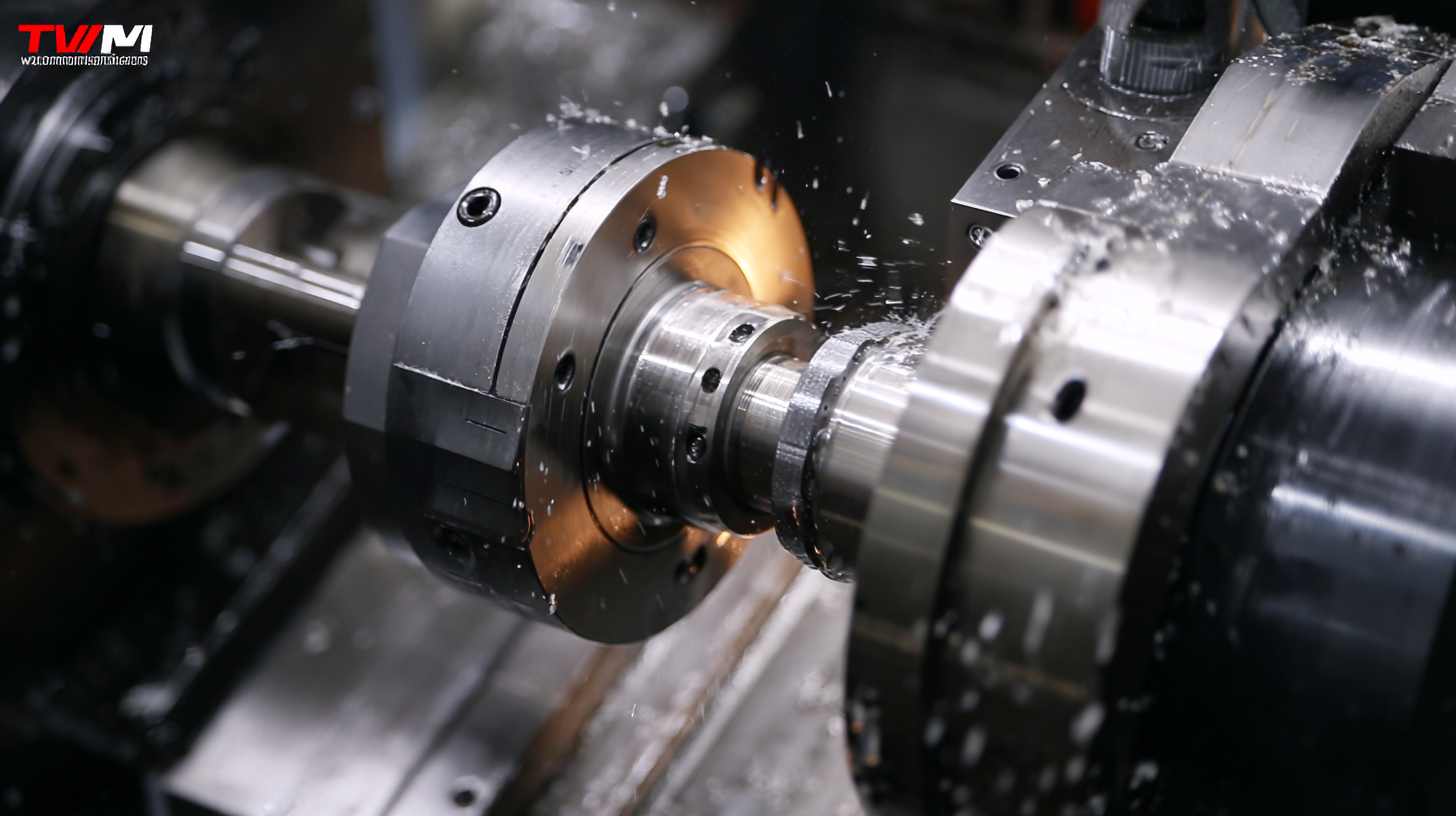

Understanding the Impact of Certification on Machine Quality and Safety

In today's competitive manufacturing landscape, understanding the impact of certifications on the quality and safety of CNC turning machines is crucial for businesses aiming to invest wisely in their machinery. Certifications such as ISO 9001, CE, and those specific to the industry, ensure that machines meet stringent quality controls and safety standards. According to a report by Grand View Research, the global CNC machinery market is expected to reach $100 billion by 2025, driven in part by the adoption of certified equipment that guarantees reliability and performance.

Certified machines not only enhance operational safety but also minimize the risk of costly downtimes. A study published by Technavio reveals that companies investing in certified equipment have reported a 15% reduction in maintenance costs and a significant decrease in workplace incidents. Moreover, certified CNC turning machines often come with comprehensive warranties and customer support, further assuring users of their investment. As manufacturers seek to maximize productivity while ensuring compliance with international standards, the importance of understanding and selecting certified machinery cannot be overstated.

Essential Documentation for Exporting CNC Turning Machinery

When it comes to exporting CNC turning machinery, having the right documentation is crucial. This includes understanding import and export certifications that ensure compliance with international regulations. According to industry reports, the global CNC machine tool market is expected to reach over $100 billion by 2025, making it imperative for manufacturers to navigate export requirements efficiently. Certifications not only facilitate smoother transactions but also enhance buyer confidence, critical for competitive success in today's market.

Tips for exporters include researching specific certification requirements for the target country, as these can vary widely. For instance, the International Organization for Standardization (ISO) certifications can significantly impact market access and performance metrics. Additionally, staying informed about sanctions and export controls, much like those currently affecting geopolitical landscapes, is vital. Exporting companies must adopt a proactive approach to compliance, potentially involving legal consultations to ensure adherence to all regulations.

Another critical tip is to maintain organized and up-to-date documentation for all transactions. This should include pro forma invoices, packing lists, and certificates of origin, as these are often required at customs. Being meticulous with these details not only avoids delays but also positions your company for greater trust and reliability in the global machining market.

Navigating International Standards for CNC Equipment Compliance

In today's global market, understanding the intricacies of import and export certifications is vital for manufacturers, particularly those dealing with CNC turning machines. Navigating international standards for equipment compliance can be a daunting task, as countries impose various regulations to ensure safety, quality, and environmental responsibility. Companies must familiarize themselves with these standards to avoid costly delays and penalties in both importing and exporting their products.

The recent developments in maritime trade underscore the importance of streamlined processes for legal entry and exit. Modernizing facilities, like shipyards, can significantly enhance the efficiency of trade operations, enabling businesses to adhere to international compliance standards more effectively. Similarly, leveraging technologies such as AI can facilitate compliance with environmental, social, and governance (ESG) regulations, ensuring sustainable sourcing and transparent supply chains. By staying informed and compliant, manufacturers of CNC machines can not only enhance their market presence but also contribute to a more responsible and efficient global economy.

Tips for Choosing the Right Certification for Your CNC Machine Needs

When selecting a CNC turning machine, understanding the various import and export certifications is essential for ensuring compliance and quality. Certifications not only demonstrate that the machine meets industry standards, but they also signify reliability in performance. To choose the right certification for your needs, consider the specific market requirements and the certification bodies recognized in your region.

One important tip is to check for internationally recognized certifications such as ISO 9001 or CE marking. These certifications can assure you that the CNC turning machine adheres to high-quality management standards and is safe for use in various applications. Additionally, it's wise to evaluate the manufacturer's reputation and the certifications they possess, as this can significantly influence the machine's performance and durability over time.

Another key consideration is the intended application of the CNC machine. Different industries may require specific certifications that address environmental standards, safety regulations, or energy efficiency. Take the time to research which certifications align best with the demands of your particular field to ensure you make a well-informed selection that meets both your operational and regulatory needs.