Why is Welded Wire Mesh Important for Construction and Security?

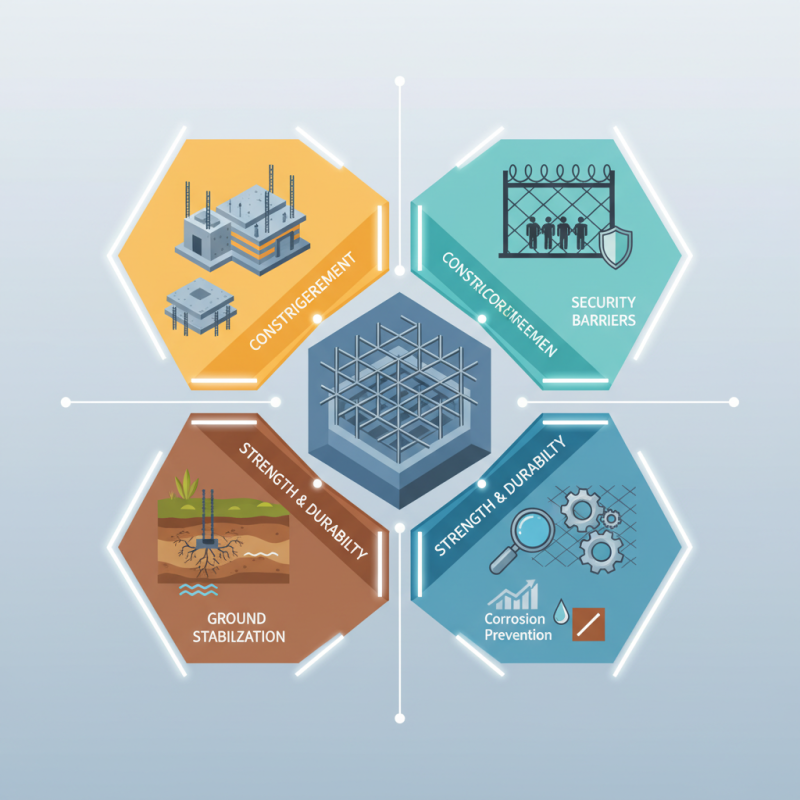

welded wire mesh plays a crucial role in modern construction and security. According to a report by the Global Market Insights, the welded wire mesh market is projected to exceed USD 6 billion by 2026, reflecting its growing significance. This versatile material is used in various applications, from reinforcing concrete structures to providing security for fences. Its strength and durability make it a preferred choice among contractors.

The steel wires used in welded wire mesh are precisely welded at intersections, ensuring high tensile strength. This feature minimizes the risk of structural failures. For instance, in high-seismic areas, welded wire mesh improves the integrity of buildings. A study from the American Concrete Institute highlighted that the inclusion of welded wire mesh in concrete slabs can enhance load-bearing capacity.

While welded wire mesh is efficient, it is not without challenges. Proper installation is vital to prevent issues like corrosion and degradation over time. Experts recommend regular inspections to maintain security and structural integrity. As demand rises, attention to quality standards is essential to avoid potential pitfalls in construction projects.

Importance of Welded Wire Mesh in Construction Projects

Welded wire mesh is a crucial element in construction projects. It provides essential reinforcement for concrete structures. This mesh consists of intersecting wires, creating a grid that enhances strength and durability. Builders often use it in floors, walls, and ceilings, ensuring stability in various types of buildings.

Using welded wire mesh can prevent cracking and improve load distribution. Yet, it’s important to choose the right gauge and spacing for specific applications. Poor selection may lead to structural issues later. Moreover, while welded wire mesh is cost-effective, it can rust if not properly coated. This can undermine its integrity over time.

In security applications, welded wire mesh serves as a deterrent to unauthorized access. It’s used in fencing and barriers, providing visibility without sacrificing safety. However, relying solely on mesh can be naive. A determined intruder might find ways around it. Therefore, combining it with other security measures enhances overall protection. Each construction project requires thoughtful consideration of material choices and their long-term implications.

Importance of Welded Wire Mesh in Construction Projects

Key Benefits of Using Welded Wire Mesh for Structural Integrity

Welded wire mesh is crucial in construction. It enhances structural integrity and stabilizes buildings. This mesh consists of cross wires that are welded at their intersections. This design allows for even weight distribution across the structure.

One key benefit is its versatility. Welded wire mesh can be used in walls, floors, and ceilings. This adaptability makes it popular for various construction projects. The material is also durable and weather-resistant. It withstands adverse conditions over time.

However, some might overlook its proper installation. If not correctly placed, the mesh can compromise strength. Regular inspection is also important. Small damages can lead to larger structural issues later. When used correctly, welded wire mesh offers long-lasting security and strength. It’s a vital component of modern architecture.

Applications of Welded Wire Mesh in Security Fencing

Welded wire mesh plays a vital role in security fencing. Its strong and durable structure makes it an ideal choice for protecting properties. Often used in commercial and residential settings, it effectively deters unauthorized access. This type of fencing allows visibility while still providing a robust barrier. Many areas utilize it to enhance security measures.

In addition, welded wire mesh is adaptable. It can be shaped and configured to meet various needs. Some installations include adding barbed wire on top for extra protection. This small addition can impact security significantly. Community parks and schools often rely on this mesh for safe boundaries. While it is effective, some installations may require maintenance over time. Rust or wear may occur in harsh environments.

Installation is key to its effectiveness. A poorly installed fence can compromise security. It is crucial to ensure that gates are secured properly. Although welded wire mesh is strong, the details matter. Each project requires attention to the specific environment and needs. The versatility of welded wire mesh makes it an excellent choice, but its effectiveness hinges on proper application and upkeep.

Durability and Longevity of Welded Wire Mesh in Various Environments

Welded wire mesh is a cornerstone in construction and security. Its durability makes it ideal for various environmental conditions. Whether used in fencing, concrete reinforcement, or as a safety barrier, it withstands the tests of time. It resists rust and corrosion when coated properly, offering prolonged life even in harsh environments. This resilience appeals to builders and developers alike.

In many cases, using welded wire mesh can reduce the need for frequent replacements. In coastal areas, for example, exposure to salt can deteriorate other materials quickly. However, wire mesh can endure, provided it's treated correctly. Yet, some still overlook its benefits, opting for cheaper alternatives that may not perform as well. The choice to invest in reliable materials can be challenging, especially when budgets are tight. Nonetheless, considering long-term performance often pays off in the end.

The flexibility of welded wire mesh also allows it to adapt to various projects. It can be cut, bent, or formed to fit specific needs. This versatility can save time on-site, but it requires skilled handling. Misjudging the required specifications can lead to wasted resources. Finding a balance between creativity and practical use is essential when integrating welded wire mesh into any project.

Comparative Analysis of Welded Wire Mesh vs. Other Materials in Building

Welded wire mesh stands out in construction and security. It provides robust support and ensures safety with its high tensile strength. Compared to traditional materials like wood or plastic, welded wire mesh is more durable and cost-effective. According to a recent industry report, using welded wire mesh can reduce building material costs by up to 30%.

While alternatives like chain link fences offer some benefits, they often lack the structural integrity that welded wire mesh provides. This mesh can withstand heavy loads, making it suitable for reinforcing concrete structures. However, not all welded wire mesh is created equal. It's essential to source quality products to avoid failures, especially in critical applications.

Tips: Always check the specifications of mesh thickness and spacing. Better quality often means higher safety and longevity. It's worth considering the environmental impact as well. Some materials may seem cheaper at first but can lead to costly repairs later.