Exploring Innovative Alternatives to CNC Machine Parts for Enhanced Manufacturing Efficiency

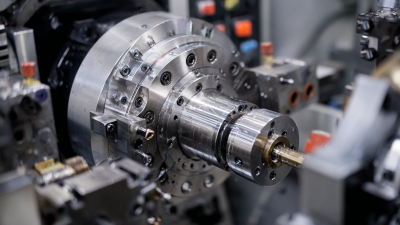

In the rapidly evolving landscape of manufacturing, traditional CNC machine parts are increasingly being scrutinized for their limitations in efficiency and adaptability. As industries strive to enhance productivity and reduce costs, it becomes essential to explore innovative alternatives that can not only match but exceed the performance of conventional CNC components. This blog delves into a variety of cutting-edge solutions and technologies, examining the reasons behind the shift towards these alternatives. We will discuss how these innovations can improve operational efficiency, shorten production times, and ultimately lead to greater cost-effectiveness in manufacturing processes. Join us as we uncover the potential of these forward-thinking options and their impact on the future of CNC machining.

Alternative Materials for CNC Machine Parts: A Closer Look

In the pursuit of enhanced manufacturing efficiency, the exploration of alternative materials for CNC machine parts has become a focal point for industries looking to push the boundaries of their capabilities. Traditional metals like aluminum and steel have long been the go-to choices due to their strength and availability; however, the advent of composite materials and advanced polymers presents exciting opportunities for manufacturers. These innovative alternatives not only reduce the weight of machine components but also offer superior resistance to wear, corrosion, and thermal stress, thereby extending the lifespan of parts and improving overall operational efficiency.

Furthermore, the implementation of 3D printing technologies has revolutionized the way manufacturers approach the creation of CNC machine parts. Materials like nylon, carbon fiber composites, and even biodegradable plastics can be utilized in additive manufacturing processes, resulting in intricate designs that are both lightweight and robust. This flexibility allows for faster prototyping and production cycles, enabling manufacturers to adapt swiftly to market demands. By integrating these alternative materials into their production lines, companies can not only enhance performance but also reduce material waste and energy consumption, paving the way for a more sustainable manufacturing future.

The Role of Additive Manufacturing in Reducing CNC Dependency

Additive manufacturing (AM) is rapidly reshaping the landscape of manufacturing by offering innovative alternatives to traditional CNC machining. According to a report by Wohlers Associates, the global additive manufacturing market is projected to grow from $12.6 billion in 2020 to $35.4 billion by 2024, indicating a significant shift towards AM technologies. This growth highlights the potential for reducing dependency on CNC machining, which traditionally involves extensive labor and time-consuming processes for producing complex parts.

One of the key advantages of additive manufacturing is its ability to minimize waste and optimize production. A study from the Massachusetts Institute of Technology (MIT) found that AM can reduce material waste by up to 90% compared to subtractive methods like CNC machining. This efficiency not only contributes to cost savings but also aligns with sustainability goals in the manufacturing sector. By leveraging AM technologies, manufacturers can produce lightweight, intricate designs that are difficult or impossible to achieve with CNC, thus enhancing overall manufacturing efficiency and product performance.

Exploring Innovative Alternatives to CNC Machine Parts for Enhanced Manufacturing Efficiency

| Part Type | CNC Machining Time (hrs) | Additive Manufacturing Time (hrs) | Material Cost ($) | Weight Reduction (%) | Production Volume (units) |

|---|---|---|---|---|---|

| Gear | 5 | 2 | 150 | 30 | 100 |

| Bracket | 3 | 1 | 75 | 25 | 200 |

| Connector | 2 | 0.5 | 50 | 20 | 300 |

| Housing | 8 | 3 | 200 | 40 | 150 |

| Mounting Plate | 4 | 1.5 | 100 | 35 | 250 |

Cost-Benefit Analysis of Innovative Part Alternatives in Manufacturing

As the manufacturing industry continues to evolve, exploring innovative alternatives to CNC machine parts presents a compelling opportunity for enhancing efficiency. A recent report by MarketsandMarkets indicates that the global additive manufacturing market is projected to grow from $12.6 billion in 2021 to $35.3 billion by 2026, signifying a shift towards more versatile production methods that reduce lead times and optimize costs.

Innovative alternatives such as 3D printing not only streamline the manufacturing process but also enable the use of lightweight materials that can substantially improve the strength-to-weight ratio of components.

Cost-benefit analyses reveal that companies adopting these innovative approaches can realize significant savings. According to a survey conducted by Deloitte, 60% of manufacturers reported cost reductions ranging from 10% to 30% after transitioning to additive manufacturing technologies. These benefits stem from decreased material waste and the capability to produce complex geometries that traditional CNC methods may struggle with. Furthermore, as supply chain disruptions have become commonplace, adopting these alternatives enhances resilience by facilitating on-demand production without reliance on extensive inventories. By investing in these innovative part alternatives, manufacturers not only lower their operational costs but also position themselves at the forefront of industry advancements.

Enhancing Production Speed: Non-CNC Solutions Worth Considering

As manufacturing industries continue to evolve, the quest for enhanced production speed has led many to explore non-CNC alternatives that promise to streamline processes and reduce costs. While CNC machines are lauded for their precision and automation capability, advancements in materials and technology are giving rise to innovative methods that can complement or even replace traditional CNC methods. Techniques such as additive manufacturing and advanced robotics are rapidly gaining traction, allowing for quicker prototyping and more flexible manufacturing flows.

As manufacturing industries continue to evolve, the quest for enhanced production speed has led many to explore non-CNC alternatives that promise to streamline processes and reduce costs. While CNC machines are lauded for their precision and automation capability, advancements in materials and technology are giving rise to innovative methods that can complement or even replace traditional CNC methods. Techniques such as additive manufacturing and advanced robotics are rapidly gaining traction, allowing for quicker prototyping and more flexible manufacturing flows.

China is emerging as a formidable player in this arena, showcasing its capabilities in integrating these innovative technologies within its industrial sectors. This shift may signal a new competitive landscape for the West, compelling manufacturers to rethink their strategies and consider alternative approaches that not only bolster efficiency but also enhance overall production quality. By examining these alternatives, manufacturers could unlock new opportunities for growth and resilience in an increasingly competitive global market.

Case Studies: Successful Implementations of Alternative Manufacturing Methods

In the realm of advanced manufacturing, the Industrial Internet of Things (IIoT) has emerged as a key driver for transformation. By integrating smart technologies, IIoT enables comprehensive monitoring and control at every level of production. This transition not only optimizes efficiency but also paves the way for innovative approaches to manufacturing. Case studies from various industries illustrate how IIoT implementations have revolutionized operations, leading to significant cost savings and enhanced product quality.

In the realm of advanced manufacturing, the Industrial Internet of Things (IIoT) has emerged as a key driver for transformation. By integrating smart technologies, IIoT enables comprehensive monitoring and control at every level of production. This transition not only optimizes efficiency but also paves the way for innovative approaches to manufacturing. Case studies from various industries illustrate how IIoT implementations have revolutionized operations, leading to significant cost savings and enhanced product quality.

One notable development in this context is the breakthrough achieved by researchers at a prominent university in harnessing 3D printing technology for automotive components, particularly headlights. This innovative method showcases a shift from traditional manufacturing practices, resulting in improved precision and production rates. As industries increasingly adopt alternative manufacturing methods, the lessons learned from these successful implementations highlight the vital role of IIoT in facilitating smarter, more efficient manufacturing processes. By focusing on these advancements, companies can remain competitive while embracing the future of manufacturing.

Related Posts

-

Top 10 Innovative CNC Machine Parts You Didn't Know You Needed

-

Essential Checklist for Sourcing Quality CNC Machine Parts in Global Markets

-

Insights on Best CNC Lathe Parts in 2025 Industry Trends and Comprehensive Comparison Guide

-

Future Trends in Best CNC Machine Parts Market Analysis for 2025 with Real World Examples

-

What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency

-

The Ultimate Guide to Choosing the Best CNC Mill for Your Business Needs