How to Optimize CNC Mill Performance for Maximum Efficiency and Precision

In the rapidly evolving landscape of manufacturing, optimizing CNC mill performance is essential for achieving maximum efficiency and precision. According to a report by the International Federation of Robotics, the global market for CNC machines is projected to reach $100 billion by 2025, highlighting the increasing reliance on automated processes.

With industries facing the pressure of reducing operational costs while maintaining high-quality output, it is vital for manufacturers to focus on enhancing the capabilities of their CNC mills. Research indicates that optimizing machining parameters can lead to a 20% increase in productivity and a significant reduction in waste. This guide aims to provide actionable strategies for tuning CNC mill operations that not only improve performance but also ensure precision, ultimately positioning businesses to compete effectively in an increasingly demanding market.

Understanding the Key Variables in CNC Milling for Enhanced Performance Comparison

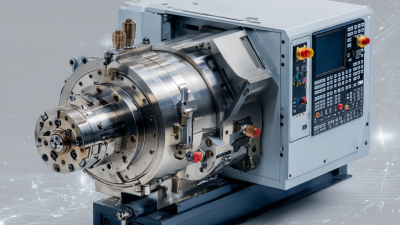

Optimizing CNC mill performance hinges on understanding the key variables that influence efficiency and precision. These variables include feed rate, spindle speed, and material properties. Achieving the right balance between these factors can significantly enhance machining outcomes.

For instance, increasing the feed rate allows for faster production but may compromise surface finish if increased too much. Careful calibration is essential to find the sweet spot that maximizes productivity while maintaining quality.

Tip: Regularly monitor the spindle speed as it directly affects tool wear and energy consumption. Adjusting this parameter according to material hardness can significantly extend tool life and reduce operational costs.

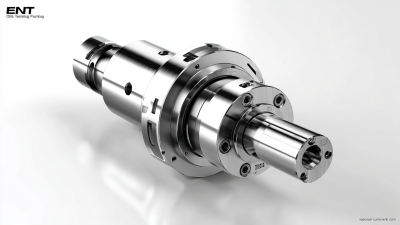

Moreover, maintaining the proper tooling is crucial. The choice of cutting tools, their geometry, and material must align with the specific tasks at hand. Tools designed for high-speed machining, for example, can dramatically improve performance when used on the right materials.

Tip: Implement routine inspections of cutting tools and tooling systems; replacing worn tools promptly can prevent additional costs associated with prolonged machining times and poor-quality outputs.

By focusing on these key variables, CNC operators can achieve remarkable improvements in both efficiency and precision.

Analyzing Cutting Tool Materials: Carbide vs. High-Speed Steel in CNC Milling

When optimizing CNC mill performance, the choice of cutting tool material is crucial. Carbide and high-speed steel (HSS) are the two primary materials in CNC milling, each offering unique advantages. Carbide tools, known for their hardness and wear resistance, can operate at higher speeds and feed rates. According to a report by the International Journal of Machine Tools and Manufacture, carbide tools can improve machining productivity by up to 30% compared to HSS tools, especially in tough materials.

In contrast, high-speed steel tools are more economical and better for machining softer materials. They retain their cutting edge longer at lower speeds, which can translate to cost savings in specific applications. A study conducted by the American Society of Mechanical Engineers indicated that using HSS can be beneficial for jobs requiring intricate detailing, where tool flexibility is a priority.

Tip 1: Always match the tool material to the specific application to maximize efficiency and precision. Carbide is ideal for hard materials, while HSS works well with softer ones.

Tip 2: Regularly monitor tool wear to determine when to switch cutting tools. Early detection can prevent unexpected downtimes and maintain consistent product quality.

Tip 3: Implement optimal feed rates based on the tool material used. Running carbide tools at higher speeds can dramatically reduce cycle time while ensuring precision.

Optimizing Feed Rates and Speeds: Finding the Ideal Balance for Precision

When it comes to CNC milling, achieving the perfect balance between feed rates and spindle speeds is crucial for enhancing both efficiency and precision. The optimal feed rate is dependent on several factors, including the material being machined, the type of cutting tool used, and the desired surface finish. A higher feed rate may decrease machining time but can lead to reduced precision and increased tool wear, while a slower feed rate can improve accuracy but extend production time. Therefore, it’s essential to determine a sweet spot where efficiency does not compromise the quality of the output.

When it comes to CNC milling, achieving the perfect balance between feed rates and spindle speeds is crucial for enhancing both efficiency and precision. The optimal feed rate is dependent on several factors, including the material being machined, the type of cutting tool used, and the desired surface finish. A higher feed rate may decrease machining time but can lead to reduced precision and increased tool wear, while a slower feed rate can improve accuracy but extend production time. Therefore, it’s essential to determine a sweet spot where efficiency does not compromise the quality of the output.

Moreover, spindle speed plays a vital role in the cutting process. Selecting the right RPM (Revolutions Per Minute) directly influences the cutting temperature and tool life. For harder materials, slower spindle speeds are often recommended to prevent overheating and fracturing. Conversely, softer materials can be machined at higher speeds to maintain productivity. Integrating these two elements effectively—feed rates and spindle speeds—can significantly elevate CNC mill performance. By continuously monitoring and adjusting these parameters, manufacturers can achieve lower cycle times while maintaining the precision necessary for high-quality output.

The Role of CNC Mill Calibration and Maintenance on Operational Efficiency

Calibration and maintenance are critical components in optimizing the performance of CNC mills. According to a report by the National Institute of Standards and Technology (NIST), properly calibrated machines can improve operational efficiency by up to 10%. Regular calibration ensures that cutting tools are aligned correctly, enhancing precision and reducing material waste. When CNC mills are not calibrated, even minor discrepancies can lead to significant errors, impacting the overall quality of the final product.

To maintain optimal performance, it's vital to implement a structured maintenance schedule. A study conducted by the American Machine Tool Distributors' Association (AMTDA) revealed that preventive maintenance can extend equipment lifespan by 20% and reduce unexpected downtime by 30%. Regularly checking and replacing worn-out parts, lubricating moving components, and cleaning machine systems play a significant role in maintaining a CNC mill’s efficiency.

**Tip:** Perform a monthly calibration check to ensure the machine maintains required precision levels. **Tip:** Establish a weekly maintenance log that includes checks on coolant levels and tool conditions to prevent minor issues from escalating. Adhering to these practices not only enhances efficiency but also ensures high-quality output, fostering long-term productivity.

Optimization of CNC Mill Performance: Calibration and Maintenance Impact

This chart illustrates the impact of CNC mill calibration and maintenance on operational efficiency. As shown, both calibration and maintenance processes significantly enhance the operational efficiency, demonstrating the importance of regular upkeep in maximizing precision and performance.

Comparative Analysis of Different CNC Mill Designs and Their Impact on Performance

When evaluating the performance of CNC mills, the design of the mill cutter plays a crucial role in determining efficiency and precision. Specifically, a large helix angle in the mill cutter can significantly affect the axial and radial forces experienced during machining. As the helix angle increases, the axial force on the end mill tends to rise while the radial force and vibration decrease. This phenomenon is essential for achieving smoother cuts and extending tool life, as reduced vibration minimizes wear on the cutter and the workpiece.

When evaluating the performance of CNC mills, the design of the mill cutter plays a crucial role in determining efficiency and precision. Specifically, a large helix angle in the mill cutter can significantly affect the axial and radial forces experienced during machining. As the helix angle increases, the axial force on the end mill tends to rise while the radial force and vibration decrease. This phenomenon is essential for achieving smoother cuts and extending tool life, as reduced vibration minimizes wear on the cutter and the workpiece.

Tips for Optimization:

1. Select the Right Helix Angle: Choosing a cutter with an appropriate helix angle can enhance chip evacuation and reduce cutting forces, leading to improved surface finishes and higher production rates.

2. Monitor Cutting Conditions: Regularly inspect and adjust cutting speeds and feeds based on the specific materials being machined. Proper settings can help balance the axial and radial forces, resulting in optimal performance.

3. Regular Maintenance: Keep your CNC mill and cutters well-maintained. Regular checks ensure that any wear and tear are addressed promptly, preventing performance degradation and ensuring precision in manufacturing processes.

By understanding the impact of different CNC mill designs and making informed adjustments to cutter selection and operating conditions, users can significantly enhance the efficiency and accuracy of their machining operations.

Related Posts

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

Emerging Trends in CNC Vertical Machining Centers for 2025 A Comprehensive Guide

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy