How to Optimize Production Efficiency with CNC Turning Centers

In today's rapidly evolving manufacturing landscape, optimizing production efficiency is crucial for maintaining competitiveness, and CNC turning centers play an essential role in this process. According to a recent report by the Association for Manufacturing Technology, the CNC machining market is expected to reach USD 100 billion by 2025, driven by advancements in automation and precision machining techniques.

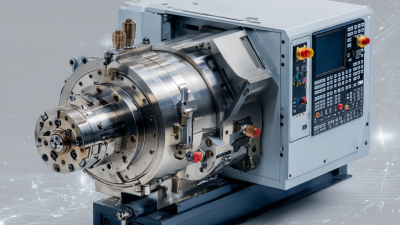

CNC turning centers, known for their ability to produce high-precision components with minimal human intervention, have become indispensable tools in various industries, including automotive and aerospace. By leveraging the capabilities of CNC turning centers, manufacturers can significantly reduce lead times and production costs while enhancing product quality. Consequently, understanding how to effectively utilize these sophisticated machines will empower businesses to streamline their operations and meet the growing demand for customized solutions.

Understanding CNC Turning Centers: The Key Components and Their Functions

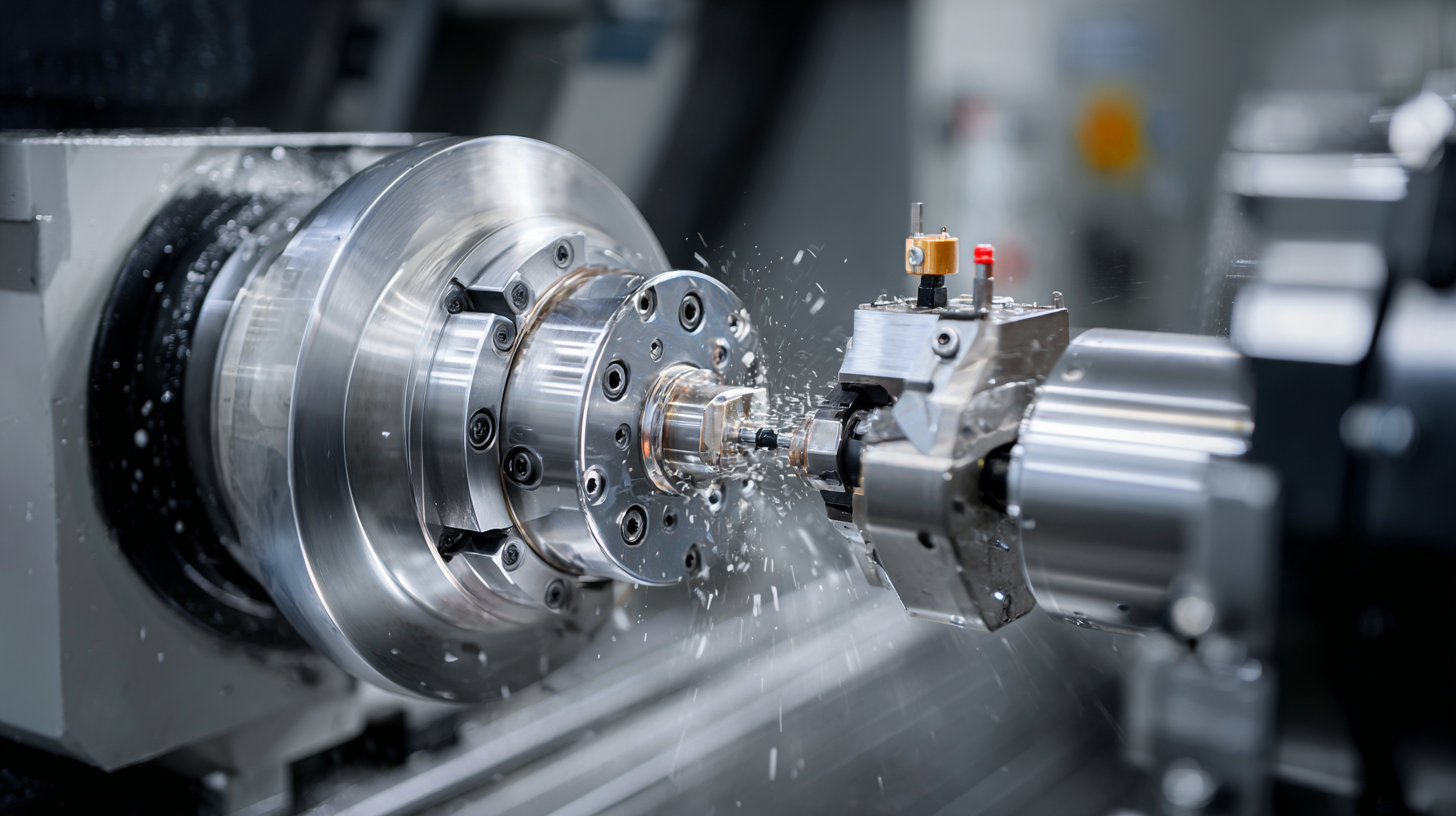

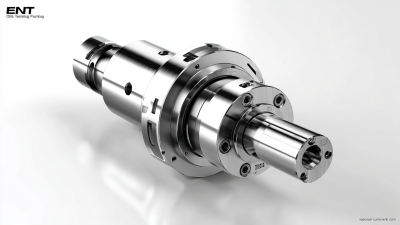

CNC turning centers are pivotal in modern manufacturing, significantly enhancing production efficiency. These advanced machines are composed of key components that work in unison to execute precise machining tasks. The primary feature is the spindle, which rotates the workpiece at high speeds, allowing for accurate shaping and cutting. This rotational motion, combined with the movement of various tools, enables the creation of complex geometries that are essential in various industries, from automotive to aerospace.

Another critical component is the tool turret, which holds multiple cutting tools and allows for quick tool changes, facilitating diverse operations without the need for manual intervention. This automation not only speeds up production but also reduces the risk of human error. Additionally, the associated control systems implement advanced programming capabilities, enabling operators to produce intricate designs with minimal setup time. Understanding these components and their functions is essential for optimizing production efficiency with CNC turning centers, streamlining processes, and improving overall throughput.

Identifying Production Bottlenecks: Common Issues in CNC Turning Efficiency

In the realm of CNC turning, identifying production bottlenecks is essential for enhancing efficiency. Common issues that impede productivity include tool wear, programming errors, and inadequate machine maintenance. A study by the American Society of Mechanical Engineers revealed that about 20% of production time is often lost due to insufficient setup protocols and poor workflow management. Understanding these bottlenecks allows manufacturers to target their efforts effectively and reduce downtime.

To mitigate these common issues, implementing best practices can significantly boost CNC turning efficiency. For instance, optimizing tooling methods based on the material being processed can lead to a 30% increase in productivity. Regular maintenance schedules should be incorporated to prevent unexpected machine failures, as data suggests that predictive maintenance can reduce downtime by up to 50%.

Here are a few quick tips to enhance productivity: First, invest in advanced CNC software for better programming that can minimize errors. Second, conduct regular training sessions for operators to keep their skills sharp and aware of the latest techniques. Lastly, analyze production data frequently to identify emerging bottlenecks before they escalate, which can further streamline operations.

Implementing Best Practices for Tool Selection and Setup in CNC Turning

When it comes to optimizing production efficiency in CNC turning centers, the initial step is often focused on the effective selection and setup of tools. Choosing the right tool for the job is crucial; it not only affects the quality of the final product but also influences the overall machining time and costs. High-quality tools designed for specific materials can significantly enhance performance and extend tool life.

**Tip 1:** Always refer to the material specifications and machining characteristics when selecting tools. For instance, when working with harder materials, opt for carbide or ceramic tools that can withstand higher temperatures and wear rates.

Setting up the tools correctly is equally important. An improper setup can lead to increased vibration, poor surface finish, and even machine damage. Spend adequate time ensuring that tools are aligned precisely and that their cutting parameters are set according to the manufacturer's recommendations.

**Tip 2:** Use a consistent tightening sequence when securing tools; this minimizes the risk of deformation and maintains accuracy during operations.

Incorporating these best practices in tool selection and setup not only maximizes efficiency but also contributes to a smoother workflow and better end results.

Optimizing Production Efficiency with CNC Turning Centers

Utilizing Automation and Software Solutions to Streamline CNC Operations

In the ever-evolving landscape of CNC machining, automation and software solutions emerge as key drivers for optimizing production efficiency. The integration of advanced technologies allows manufacturers to streamline their operations, reducing manual intervention and minimizing errors. By embracing automated systems, businesses can achieve a level of precision and speed previously unattainable, ensuring consistent quality in their output.

Software solutions play a crucial role in this transformation, offering tools that enhance workflow management, scheduling, and real-time monitoring. For instance, simulation software enables manufacturers to visualize and optimize their processes before implementation, significantly reducing downtime and improving resource allocation. This proactive approach not only boosts productivity but also helps companies adapt to fluctuating market demands while addressing the growing challenge of skilled labor shortages in the CNC field. As the industry looks toward a future where efficiency is paramount, the synergy of automation and innovative software stands at the forefront of manufacturing excellence.

Continuous Improvement: Analyzing Data for Ongoing CNC Efficiency Gains

In the quest for enhanced productivity, CNC turning centers stand out as vital tools for manufacturers. A pivotal aspect of optimizing production efficiency lies in the continuous analysis of data generated during machining processes. By implementing robust data analysis techniques, organizations can uncover patterns and trends that reveal inefficiencies, leading to targeted improvements. Collecting data such as cycle times, tool wear, and machine utilization allows manufacturers to take a proactive approach to maintenance and operational management.

Moreover, regular assessment of performance metrics fosters a culture of continuous improvement. By utilizing advanced analytics, manufacturers can compare historical data against current production outcomes, identify bottlenecks, and predict potential downtimes. This real-time insight enables teams to make informed decisions that not only enhance workflow but also improve the quality of the finished products.

Embracing a data-driven mindset ensures that CNC turning centers are not merely tools of production but integral components of a dynamic and adaptive manufacturing strategy.

Related Posts

-

Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers

-

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

The Ultimate Guide to Mastering CNC Milling and Turning Techniques for Precision Engineering

-

Discover the Excellence of Quality China Made CNC Machine Tools for Global Markets

-

How to Optimize CNC Mill Performance for Maximum Efficiency and Precision