5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

In an increasingly competitive manufacturing landscape, CNC turning has emerged as a pivotal process that propels efficiency and precision. According to recent industry reports, the global CNC lathe market is projected to reach USD 6.8 billion by 2026, growing at a CAGR of 6.2% from 2021 to 2026. This significant growth underscores the demand for high-quality manufacturing solutions capable of meeting diverse industrial needs. As manufacturers seek to enhance productivity and reduce operational costs, CNC turning offers a compelling solution through automation, accuracy, and reduced lead times.

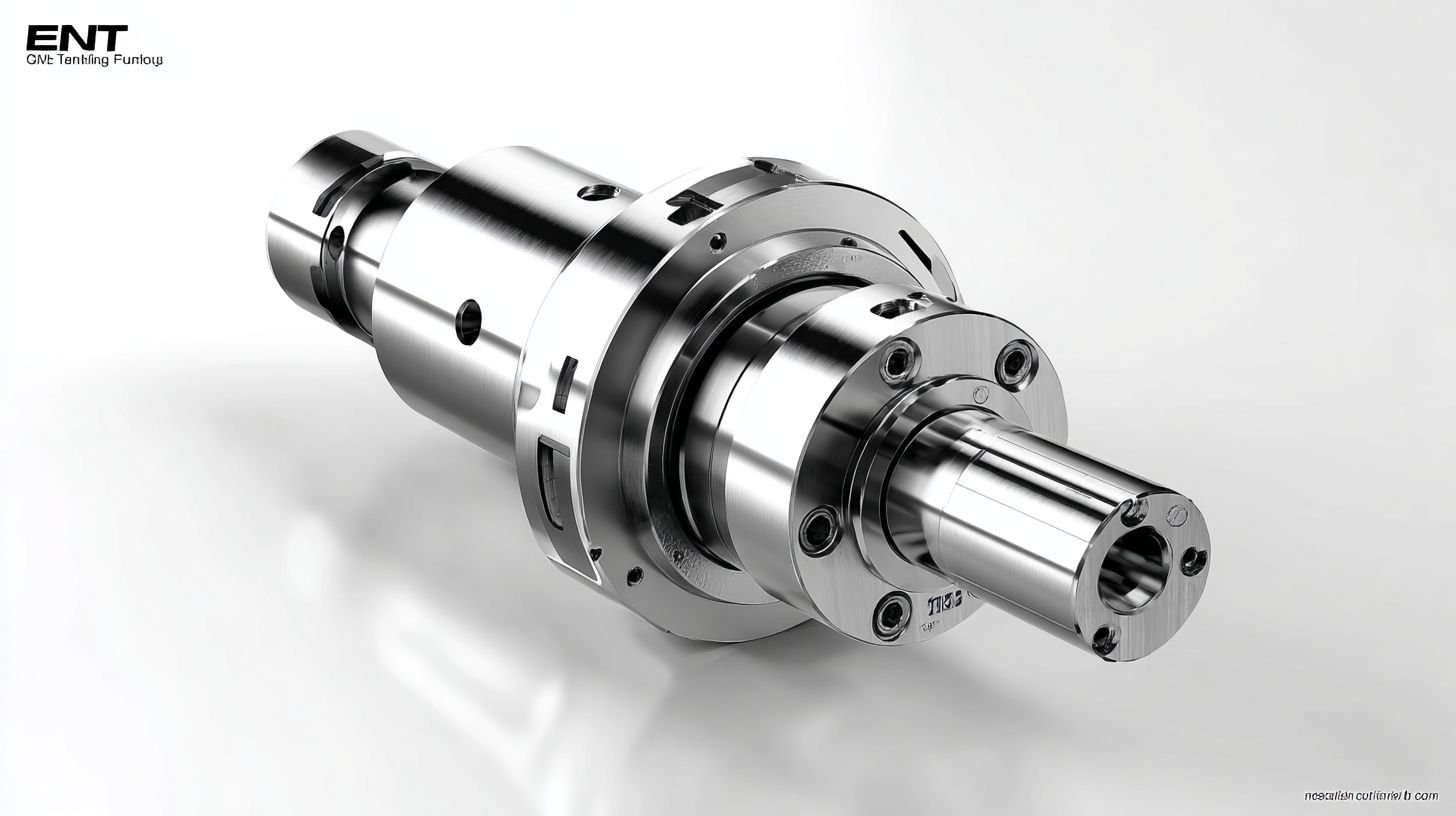

With its ability to produce complex geometries and tight tolerances, CNC turning not only enhances the manufacturing process but also positions businesses to compete effectively in a global market where quality is paramount. Ultimately, embracing the advantages of CNC turning can be the key to unlocking operational excellence and gaining a competitive edge on the world stage.

With its ability to produce complex geometries and tight tolerances, CNC turning not only enhances the manufacturing process but also positions businesses to compete effectively in a global market where quality is paramount. Ultimately, embracing the advantages of CNC turning can be the key to unlocking operational excellence and gaining a competitive edge on the world stage.

Maximizing Production Capacity with Advanced CNC Turning Techniques

Maximizing production capacity in today's competitive manufacturing landscape requires the adoption of advanced techniques, particularly in CNC turning. The integration of cutting-edge technologies into CNC turning processes enables manufacturers to achieve unprecedented efficiencies. For instance, the introduction of analytical modeling and deep neural networks allows for optimizing the machining of innovative materials like LM25Al/VC composites. These advancements not only enhance machinability but also significantly reduce production times and costs, thereby directly impacting overall efficiency.

Maximizing production capacity in today's competitive manufacturing landscape requires the adoption of advanced techniques, particularly in CNC turning. The integration of cutting-edge technologies into CNC turning processes enables manufacturers to achieve unprecedented efficiencies. For instance, the introduction of analytical modeling and deep neural networks allows for optimizing the machining of innovative materials like LM25Al/VC composites. These advancements not only enhance machinability but also significantly reduce production times and costs, thereby directly impacting overall efficiency.

Moreover, the latest innovations in CNC turning centers play a pivotal role in maximizing productivity. New single-spindle models with multitasking capabilities are transforming traditional machining approaches. These machines streamline operations by incorporating built-in automation features, which facilitate faster setup times and allow for continuous production without the need for frequent manual intervention. As manufacturers embrace these advanced CNC turning techniques, they are not only boosting their production capacity but also positioning themselves at the forefront of industry innovation.

Reducing Waste and Enhancing Precision in CNC Turning Processes

In today’s manufacturing landscape, enhancing precision and minimizing waste through CNC turning processes is crucial for maintaining a competitive edge. Traditional lubrication systems, while beneficial, can be improved upon to further decrease friction and machining defects, leading to better product quality and consistency. By optimizing lubrication and other machining parameters, manufacturers can significantly reduce waste during the turning process, which not only cuts costs but also contributes to more sustainable practices.

The integration of advanced technologies such as artificial intelligence in CNC machining is revolutionizing the industry. AI-driven systems can analyze vast amounts of data in real-time, allowing for the fine-tuning of processes that enhance both precision and efficiency. This adaptability leads to smarter machining operations, reduced material waste, and ultimately, higher productivity. As companies increasingly adopt these innovative techniques, the manufacturing sector is set to experience substantial growth, underscoring the importance of CNC turning in modern industrial practices.

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

This bar chart illustrates the key benefits of CNC turning in enhancing manufacturing efficiency. The percentages represent the impact in various areas such as reduced waste, improved precision, increased production speed, lower energy consumption, and enhanced tool life. These metrics showcase how implementing advanced CNC turning can significantly streamline manufacturing processes.

The Role of CNC Turning in Meeting Industry 4.0 Standards

CNC turning plays a pivotal role in the evolution towards Industry 4.0, a paradigm characterized by smart manufacturing, interconnected systems, and real-time data analytics. According to a report by McKinsey, companies that implement smart manufacturing practices can increase operational efficiency by 25 to 30 percent through optimized processes and reduced downtime. CNC turning machines, equipped with advanced sensors and IoT connectivity, allow manufacturers to collect and analyze performance data in real time, leading to informed decision-making and proactive maintenance strategies.

Moreover, the integration of CNC turning into automated production lines enhances flexibility and responsiveness, essential features for meeting the demands of today’s fast-paced markets. A study by Deloitte indicates that manufacturers leveraging Industry 4.0 technologies have reported up to a 20% reduction in lead times. This agility allows businesses to quickly adapt to changing customer needs while maintaining high precision and quality in their output, thereby ensuring competitiveness in an increasingly automated landscape. The strategic adoption of CNC turning not only streamlines production but also aligns manufacturing processes with the broader objectives of Industry 4.0, setting the stage for sustainable growth.

Market Trends: Projected Growth of the CNC Turning Sector by 2025

The CNC turning sector is projected to experience substantial growth by 2025, driven by increasing demand for precision manufacturing across various industries. With advancements in technology and the growing adoption of automation, manufacturers are turning to CNC turning machines for their ability to produce intricate components with high accuracy and minimal human intervention. This trend is not only improving product quality but also significantly reducing lead times and operational costs.

Moreover, the integration of smart technologies into CNC turning processes further enhances efficiency. The emergence of Industry 4.0 is prompting manufacturers to utilize data analytics and IoT capabilities, allowing for real-time monitoring and optimization of production workflows. This evolution ensures that companies can swiftly adapt to market changes and customer demands while maintaining a competitive edge. As businesses continue to recognize the benefits of CNC turning, the sector is poised for continued expansion, making it an exciting area to watch in the manufacturing landscape.

5 Reasons Why Best CNC Turning Enhances Your Manufacturing Efficiency

| Reason | Description | Impact on Efficiency |

|---|---|---|

| Precision Manufacturing | CNC turning provides high accuracy in producing complex shapes. | Reduces material waste and rework time. |

| Increased Production Speed | Automated machining processes allow for faster production cycles. | Enhances overall output rates. |

| Flexibility | Easily adaptable for different materials and product designs. | Allows manufacturers to respond quickly to market demands. |

| Consistency | Maintains uniform quality across production runs. | Minimizes errors and improves customer satisfaction. |

| Reduced Labor Costs | Lower dependency on manual labor through automation. | Decreases operational costs significantly. |

Cost-Benefit Analysis: Investing in High-Quality CNC Turning Machinery

Investing in high-quality CNC turning machinery can significantly enhance manufacturing efficiency and provide substantial cost benefits. The latest market trends suggest a promising future for CNC technologies, with the metal processing machinery market expected to grow significantly by 2032. This anticipated growth indicates that businesses focusing on advanced CNC solutions will likely see increased productivity and reduced operational costs.

When considering the financial aspect, it’s essential to analyze the cost-to-benefit ratio of CNC turning investment. High-quality machinery may come with a higher upfront cost but can yield savings through improved precision, reduced waste, and faster production times. For example, exceptional accuracy in machining minimizes the need for rework, ultimately leading to cost savings.

Tips for Maximizing Your Investment:

- Regular maintenance of CNC equipment can enhance its longevity and performance, ensuring you get the most out of your investment.

- Consider training your operators to leverage the full capabilities of your CNC machinery, optimizing workflows and improving output quality.

- Stay updated with market trends and advancements in CNC technology to make informed decisions about upgrades and replacements.