7 Tips for Choosing the Best CNC Machine Parts for Enhanced Precision and Efficiency

In the world of precision machining, the right CNC machine parts can make all the difference in achieving superior results and maximizing operational efficiency. Choosing high-quality components is crucial for ensuring that your CNC machines operate at their best, delivering accuracy, reliability, and longevity. As the demand for precision engineering continues to rise, understanding how to select the best CNC machine parts becomes paramount for manufacturers and engineers alike. This blog will guide you through seven essential tips that will not only help you identify reputable manufacturers but also empower you to make informed decisions in your procurement process. By focusing on factors such as material quality, tolerances, and supplier reputation, you will be better equipped to enhance the performance of your CNC machines and achieve optimal results in your projects.

Identifying Essential CNC Machine Parts for Optimal Performance in Manufacturing

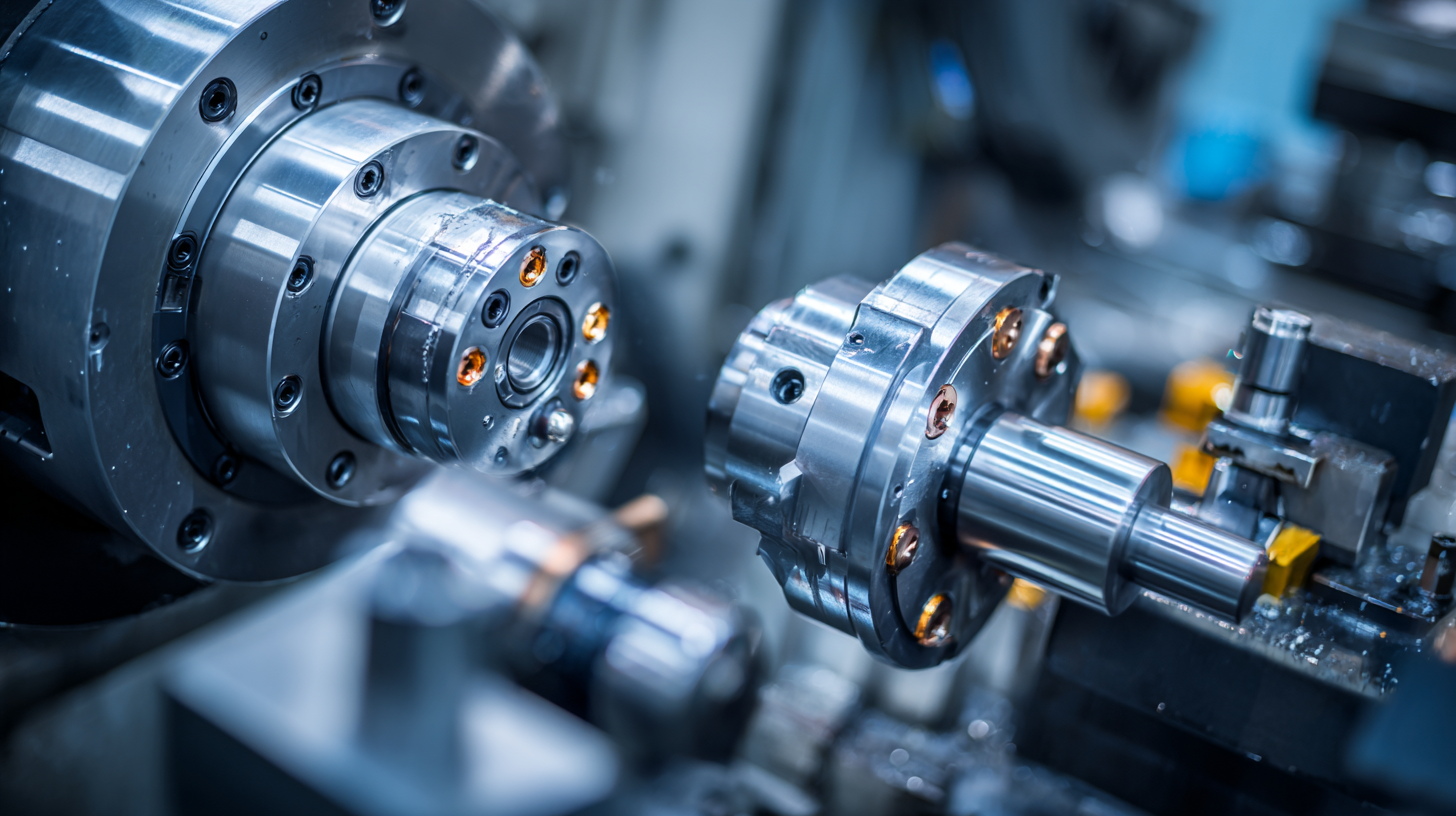

When it comes to enhancing performance in manufacturing, choosing the right CNC machine parts is crucial. Each component plays a vital role in ensuring operational efficiency and precision. Essential parts like spindles, tool holders, and linear guides are fundamental for achieving optimal results. High-quality spindles not only affect the speed and power of machining operations but also contribute to the overall accuracy. Selecting tool holders that minimize runout can significantly improve part geometry, resulting in finer finishes and tighter tolerances.

In addition to selecting individual parts, it's essential to consider how these components interact within the CNC machine. For instance, linear guides must be compatible with the machine’s architecture to offer smooth motion and minimize wear over time. Assessing compatibility and performance metrics is key in this selection process. Regular maintenance of these parts can further enhance their longevity and ensure continuous optimal performance. By focusing on the essential components of CNC machines, manufacturers can drive efficiency and precision in their operations, ultimately leading to better productivity and reduced costs.

Understanding Material Selection for CNC Parts: Balancing Cost and Quality

When it comes to selecting materials for CNC machine parts, striking the right balance between cost and quality is paramount. High-quality materials can significantly enhance the precision and efficiency of the final products, but they often come with a higher price tag.

To optimize performance while managing expenses, manufacturers must consider the specific application of the parts. For instance, using stainless steel might provide better durability and corrosion resistance compared to lower-grade metals, but the associated costs could escalate.

It’s also essential to evaluate the sourcing options available in the market. There are competitive service providers that offer advanced materials at various price points, allowing businesses to make informed decisions based on their budgetary constraints without compromising on quality. By leveraging insights into material properties, such as tensile strength and wear resistance, manufacturers can effectively align their CNC part selections with both operational needs and financial goals, ultimately driving industrial efficiency and precision.

Exploring the Role of Precision Manufacturing Tolerances in CNC Part Efficiency

When it comes to CNC machining, precision manufacturing tolerances play a critical role in enhancing the efficiency and performance of machine parts. Tolerances refer to the allowable variation in a part's dimensions, which directly affects how well components fit together and operate. By adhering to strict tolerances, manufacturers can ensure that every part produced meets specific performance criteria, ultimately leading to improved overall machine efficiency.

Furthermore, precision in tolerances not only minimizes the risk of part failure but also optimizes the machining process. Parts manufactured within the designated tolerance range require less rework and adjustment, saving time and resources. For CNC operators, this means achieving higher throughput and reducing waste, as well as delivering high-quality products to customers consistently. Emphasizing the importance of precision tolerances in the CNC manufacturing process empowers businesses to elevate their operational standards and meet the demands of an increasingly competitive market.

7 Tips for Choosing the Best CNC Machine Parts for Enhanced Precision and Efficiency

| Part Type | Material | Tolerance Level (mm) | Application | Efficiency Rating (1-10) |

|---|---|---|---|---|

| Spindle | Steel | 0.01 | Precision Machining | 9 |

| Fixture | Aluminum | 0.05 | Assemblies | 8 |

| Tool Holder | Titanium | 0.02 | Cutting Tools | 10 |

| End Mill | Carbide | 0.02 | Machining Operations | 9 |

| Collet | Brass | 0.01 | Grip Tools | 9 |

Evaluating Supplier Reliability: Key Metrics for Sourcing CNC Machine Components

When sourcing CNC machine components, supplier reliability is paramount to ensuring enhanced precision and efficiency in production. One of the key metrics to evaluate is the supplier's track record. Assessing their history of on-time deliveries and quality control measures can provide valuable insights into their dependability. Suppliers with a consistent history of meeting deadlines and delivering defect-free products are more likely to contribute positively to your CNC machining operations.

Another critical metric to consider is the level of customer support and communication provided by the supplier. A reliable supplier should be responsive and proactive in addressing any concerns or issues that may arise. Look for suppliers who offer transparent communication and are willing to work closely with you to understand your specific needs. This partnership approach not only improves the likelihood of receiving high-quality parts but also fosters a collaborative environment that can enhance overall production processes. By carefully evaluating these metrics, you can minimize risks and ensure that the CNC components sourced contribute to improved operational outcomes.

7 Tips for Choosing the Best CNC Machine Parts

Leveraging Technology: Innovations in CNC Parts for Improved Production Efficiency

In the ever-evolving landscape of manufacturing, leveraging technology in CNC machining is crucial for enhancing production efficiency. Recent industry reports indicate that adopting advanced CNC machine parts can improve operational productivity by as much as 30%. Innovations such as high-speed spindles, optimized tooling systems, and smart sensors are at the forefront of this transformation. These technologies not only facilitate faster production cycles but also enhance the precision of machining processes, reducing error rates significantly.

Additionally, the integration of IoT (Internet of Things) capabilities into CNC machinery has revolutionized maintenance and operational workflows. According to a research study from the Global Manufacturing Research Group, manufacturers utilizing smart CNC systems can achieve a 20% reduction in downtime through predictive maintenance analytics. This capability allows for real-time monitoring and timely interventions, ensuring that machines operate at peak efficiency. As the demand for higher-quality outputs grows, investing in innovative CNC parts is not just a trend, but a strategic move to stay competitive in today’s manufacturing environment.