Unlocking the Potential of Vertical CNC Machines for Precision Engineering

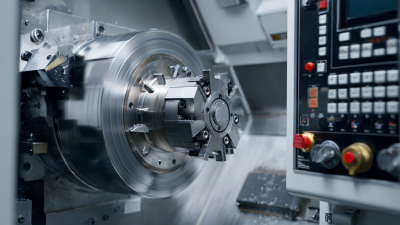

In the realm of precision engineering, the advent of vertical CNC machines represents a monumental leap forward in manufacturing technology. These machines, characterized by their upright spindle orientation, offer unparalleled accuracy and efficiency in machining complex components. As industries increasingly demand intricate designs and tighter tolerances, the vertical CNC machine stands at the forefront, capable of delivering intricate cuts and smooth finishes that are essential for modern applications. The integration of digital advancements such as advanced programming software and real-time monitoring systems not only enhances the machine's capabilities but also streamlines the production process, ultimately leading to improved productivity and reduced cycle times. This article delves into the various ways vertical CNC machines can be harnessed to unlock their full potential, exploring innovations and best practices that propel precision engineering into a new era.

Understanding the Basics of Vertical CNC Machines and Their Advantages

Vertical CNC machines have gained significant traction in precision engineering due to their versatility and capabilities. These machines utilize a vertically-oriented spindle, which can easily accommodate various tooling and setups, thereby streamlining the manufacturing process. According to industry reports, the vertical machining center market is projected to grow at a CAGR of around 5.4% from 2023 to 2028, indicating a robust demand for such technology in the manufacturing sector.

One of the key advantages of vertical CNC machines is their ability to produce intricate designs with high precision, which is vital in industries like aerospace and automotive. They allow for easier access to the workpiece, reducing setup times and improving workflow efficiency. Furthermore, advancements in motion control technology have enhanced the automation capabilities of these machines, facilitating the production of complex geometries with minimal human intervention. As manufacturers increasingly prioritize efficiency and precision, the integration of vertical CNC machines into their operations is set to become a fundamental aspect of modern manufacturing practices.

Unlocking the Potential of Vertical CNC Machines for Precision Engineering

Key Features to Look for in Vertical CNC Machines for Precision Engineering

When selecting vertical CNC machines for precision engineering, several key features play a crucial role in achieving optimal performance and reliability. First and foremost, the rigidity of the machine is essential, as it directly affects the accuracy and surface finish of machined parts. A rigid structure can withstand vibrations and forces during machining, ensuring that precision is maintained throughout the process. Additionally, the spindle speed and power contribute significantly to the versatility and efficiency of the machining operations, allowing the machine to handle a wide variety of materials and cutting tools with ease.

Moreover, advanced control systems featuring AI and automation are becoming increasingly important in vertical CNC machines. These technologies enhance operational capabilities by offering improved precision, real-time monitoring, and predictive maintenance, ultimately leading to reduced downtime and increased productivity. Furthermore, the integration of multi-axis capabilities enables complex machining operations in a single setup, streamlining workflows and further enhancing machining precision. As the market for CNC machines continues to expand, these features will be instrumental in meeting the growing demand for high-precision engineering solutions.

Unlocking the Potential of Vertical CNC Machines for Precision Engineering - Key Features to Look for in Vertical CNC Machines for Precision Engineering

| Feature | Description | Importance | Typical Range |

|---|---|---|---|

| Spindle Speed | The maximum speed at which the spindle can rotate. | Higher speeds improve material removal rates. | 8000 - 24000 RPM |

| Travel Range | The maximum movement distance of the cutting tool along the axes. | Larger travel ranges allow for bigger workpieces. | X: 600 - 2000 mm, Y: 400 - 1000 mm, Z: 400 - 800 mm |

| Tool Change Time | The time it takes to change tools in the spindle. | Faster tool changes increase overall productivity. | 1.5 - 5 seconds |

| Accuracy | The degree of conformity of the machine's output to the specified dimensions. | Precision is critical in engineering applications. | ±0.005 mm |

| Control System | Type of CNC control system used to program and operate the machine. | Advanced control systems enhance programming flexibility and efficiency. | Fanuc, Siemens, Haas |

Step-by-Step Guide to Setting Up and Operating Vertical CNC Machines

Vertical CNC machines have revolutionized precision engineering, offering significant advantages in both setup and operation. A step-by-step guide to effectively using these machines begins with proper installation. According to a report by the International Journal of Advanced Manufacturing Technology, ensuring precise leveling and alignment of the machine can enhance accuracy by up to 30%, making the initial setup critical for successful operations.

Once installed, operators should focus on familiarizing themselves with the machine’s controls and software. Training programs that emphasize programming and operational efficiency have shown to reduce error rates by up to 25%, according to findings from the Association for Manufacturing Technology. An important aspect of operation includes regular maintenance checks, which can extend the lifespan of the machine significantly. By adhering to a structured routine, businesses can maximize their investment in vertical CNC technology, leading to improved productivity and output quality.

Best Practices for Maintaining and Optimizing Vertical CNC Machines

Maintaining and optimizing vertical CNC machines is critical for precision engineering. One of the foremost best practices involves regular maintenance schedules, which include lubrication, parts inspection, and calibration checks. Consistency in maintenance not only prolongs the life of the machines but also ensures their performance remains at peak efficiency. Operators should foster a routine of keeping the machines clean and promptly addressing any signs of wear or malfunction.

Tips: To enhance the efficacy of your vertical CNC machines, consider implementing a digital maintenance log. This log can aid in tracking service intervals and automatically remind you of upcoming maintenance tasks. Additionally, training staff on the importance of these practices can further instill a culture of care and attentiveness towards the machinery.

Optimization also involves smart integration with advanced software, such as post processors. These tools bridge the gap between CAD models and CNC machines, allowing for precise control over machining operations. Understanding how to configure and utilize post processors effectively can significantly boost production accuracy and efficiency.

Tips: Regularly updating the software and ensuring compatibility with your CNC machines can prevent potential operational disruptions. Engaging in workshops and training sessions can also deepen your team’s understanding of software nuances, thereby improving workflow and productivity in the machining process.

Common Applications of Vertical CNC Machines in Precision Engineering

Vertical CNC machines play a pivotal role in precision engineering, serving a variety of applications where accuracy and customization are paramount. Industries such as aerospace, automotive, and medical manufacturing heavily rely on these machines to produce intricate components with tight tolerances. The CNC machine market is on a robust growth trajectory, projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This growth underscores the increasing demand for precision in manufacturing processes.

One prominent application of vertical CNC machines is in the production of billet crankshafts, which exemplify innovation in design and performance. These components enable engineers to achieve a higher degree of control over engine functionality, thereby enhancing performance in high-stakes environments. Additionally, with the recent advancements in CNC technology, companies are introducing specialized capabilities such as marine manufacturing projects, which further illustrate the versatility of vertical CNC machines in addressing specific industry needs. This adaptability and precision are key drivers in expanding the applications of vertical CNC technology across various sectors.

Related Posts

-

Crafting Excellence with the Best CNC Machines from China for Global Service

-

Challenges Associated with Choosing the Best CNC Milling Machine for Your Needs

-

How to Choose the Best Multi Axis CNC Machine for Your Manufacturing Needs

-

The Ultimate Guide to Choosing the Best CNC Mill for Your Business Needs

-

How to Maximize Efficiency with Vertical CNC Machine Optimization Techniques

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market